Pet feed and preparation method thereof

A pet feed and feed technology, applied in the field of pet feed, can solve the problems of lack of growth and health of feed, malnutrition of pets, threats to pet life safety, etc., achieve healthy and balanced diet, safe and hygienic pet consumption, and improve gastrointestinal digestion. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

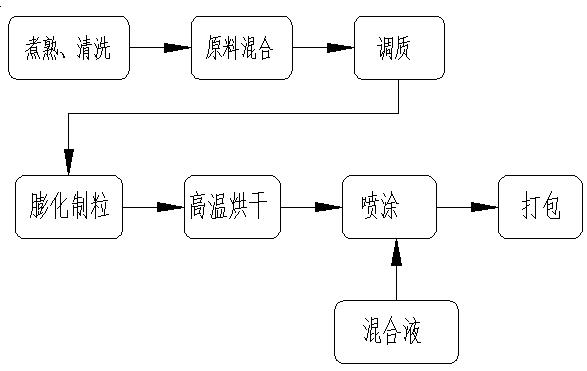

[0030] The present invention also includes a preparation method of pet feed, which is characterized in that: the preparation method is as follows:

[0031] Step 1: weighing the raw materials according to the ratio of claim 1, and cooking the boneless chicken, boneless cod and beef at high temperature;

[0032] Step 2: Mix and grind other raw materials except purple potato powder, South American salmon oil and plant extract;

[0033] Step 3: transport the pulverized mixture to a conditioner, and the conditioning time is 1-2 minutes;

[0034] Step 4: Put the tempered mixture into an extruder for extruding and granulating;

[0035] Step 5: drying the expanded feed pellets at high temperature to obtain dry feed pellets, so that the moisture content of the dry feed pellets is 9-14%, and the density is between 1.1-1.3g / cm³;

[0036] Step 6; South American salmon oil and plant extracts are mixed to make a mixture;

[0037] Step 7: Spray the mixed solution on the dry feed granules ...

Embodiment 1

[0040] Calculated in kilograms by weight, including the following raw materials: boneless chicken 49kg, boneless cod 20kg, peeled potatoes 8kg, peeled sweet potato powder 6kg, whole milk powder 4kg, beef 2kg, raw bone meat freeze-dried 2kg, South American salmon oil 2kg, peeled purple potato powder 1kg, dehydrated carrot 1kg, dehydrated apple 1kg, plant extract 1kg, cod floss 1kg, chicken freeze-dried 1kg, feed compound seasoning 1kg.

[0041] According to the above proportioning, its preparation method is as follows:

[0042] Step 1: Weigh the raw materials according to the ratio of claim 1, and cook the boneless chicken, boneless cod and beef at high temperature, the water temperature is 100°C, and the cooking time is 10 minutes;

[0043] Step 2: Mix and grind other raw materials except purple potato powder, South American salmon oil and plant extract;

[0044] Step 3: transport the pulverized mixture to a conditioner, and the conditioning time is 1 minute;

[0045] Step 4...

Embodiment 2

[0050]Calculated in kilograms by weight, including the following raw materials: boneless chicken 40kg, boneless cod 20kg, dehydrated peeled potatoes 8kg, peeled sweet potato powder 7kg, whole goat milk powder 5kg, beef 3kg, raw bone meat freeze-dried 3kg, South American salmon Oil 3kg, peeled purple potato powder 1kg, dehydrated carrot 2kg, dehydrated apple 2kg, plant extract 2kg, cod floss 2kg, chicken freeze-dried 1kg, feed compound seasoning 1kg.

[0051] According to the above proportioning, its preparation method is as follows:

[0052] Step 1: Weigh the raw materials according to the ratio of claim 1, and cook the boneless chicken, boneless cod and beef at high temperature, the water temperature is 100°C, and the cooking time is 10 minutes;

[0053] Step 2: Mix and grind other raw materials except purple potato powder, South American salmon oil and plant extract;

[0054] Step 3: transport the pulverized mixture to a conditioner, and the conditioning time is 1 minute; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com