Split type structure of electronic controller and strength simulation method thereof

An electronic controller and simulation method technology, applied in the field of numerical analysis, can solve the problems of inability to truly reflect the contact form of structural connections, inability to obtain stress and deformation calculation results, and low process assembly efficiency, so as to improve process assembly efficiency and reduce materials. cost, the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

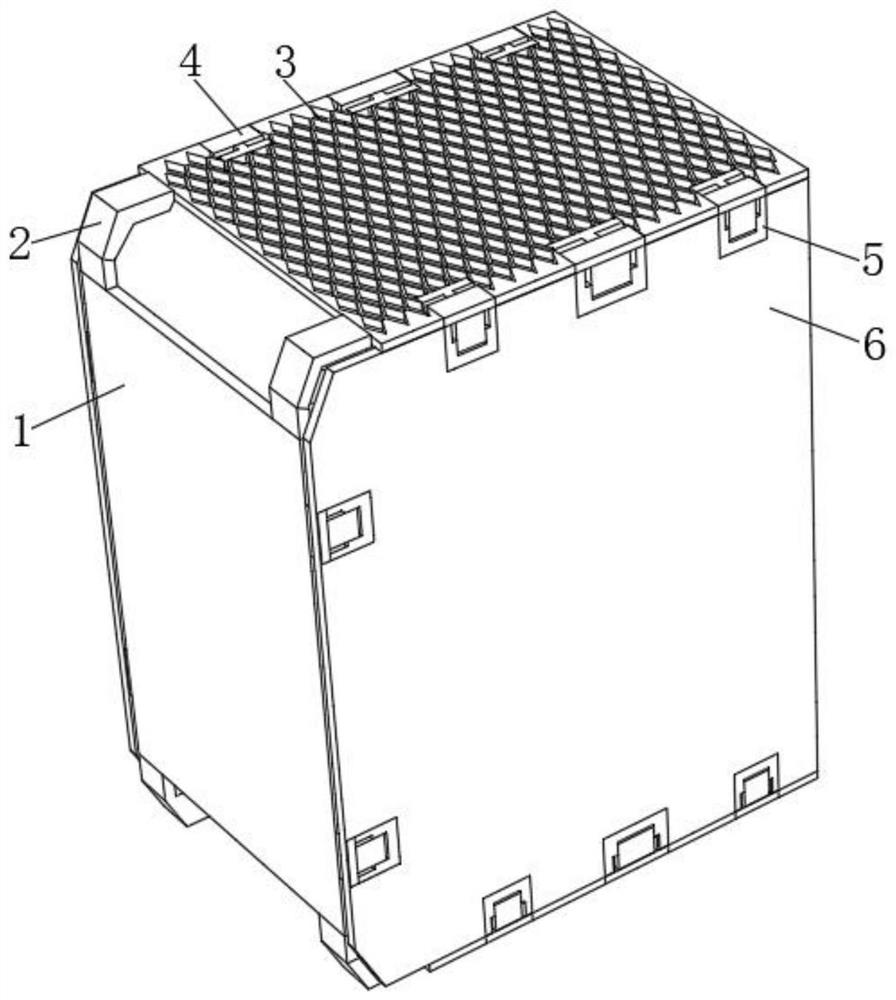

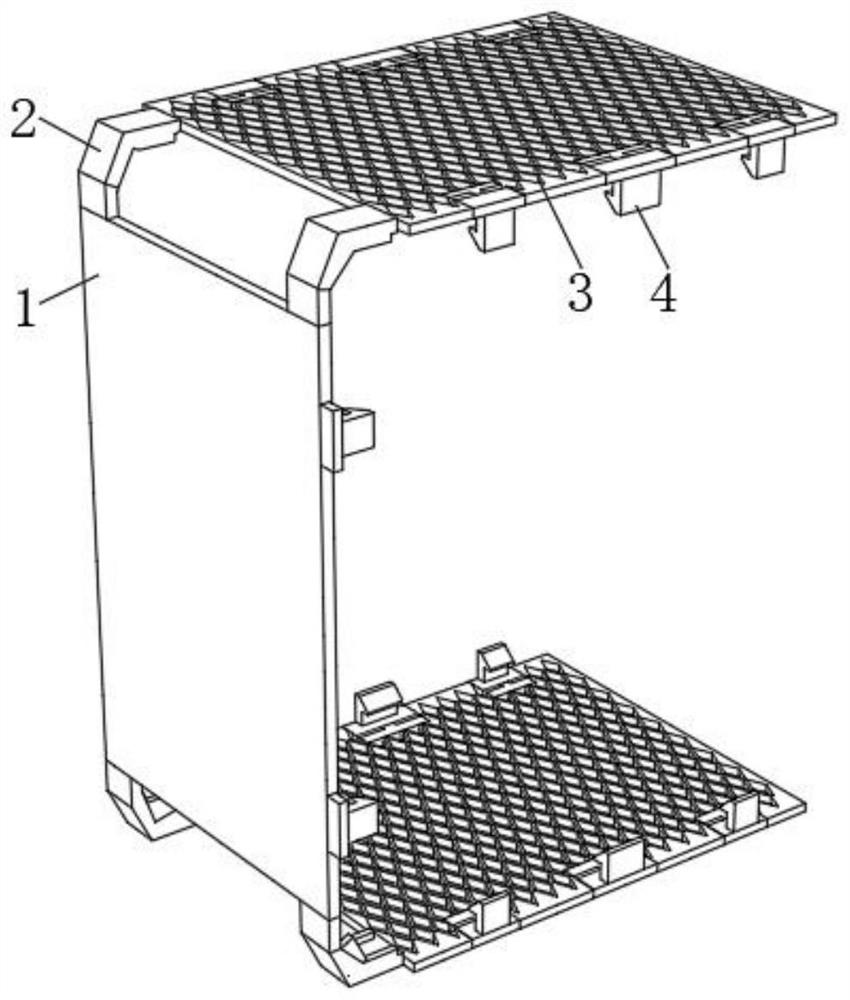

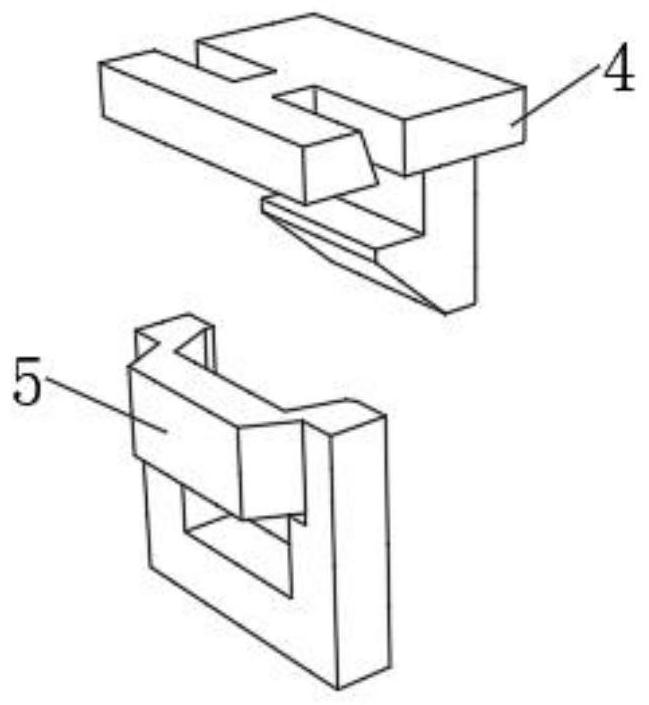

[0040] see Figure 1-3 , the present invention provides a technical solution: an electronic controller split structure, including a riser 1, the top and bottom of the riser 1 are integrally formed with a connecting piece 2 along the front and rear direction, and the connecting piece 2 is away from the side of the riser 1 Mounting boards 3 are provided, and ventilating holes are provided around the sides of the mounting boards 3 that are close to each other, which can facilitate the rapid heat dissipation of the electronic controller and prolong the service life of the electronic controller. The front and back sides of the mounting boards 3 are close to each other A buckle 4 is embedded along the left and right directions, and a card slot 5 is snapped on the buckle 4. The surface of the card slot 5 is provided with a guard plate 6 used in conjunction with the vertical plate 1. Based on the three-way anti-vibration performance of the actual working environment and To meet the re...

Embodiment 2

[0042] see Figure 1-12 , the present invention provides a technical solution: an electronic controller split structure, including a riser 1, the top and bottom of the riser 1 are integrally formed with a connecting piece 2 along the front and rear direction, and the connecting piece 2 is away from the side of the riser 1 Mounting boards 3 are provided, and ventilating holes are provided around the sides of the mounting boards 3 that are close to each other, which can facilitate the rapid heat dissipation of the electronic controller and prolong the service life of the electronic controller. The front and back sides of the mounting boards 3 are close to each other A buckle 4 is embedded along the left and right directions, and a card slot 5 is snapped on the buckle 4. The surface of the card slot 5 is provided with a guard plate 6 used in conjunction with the vertical plate 1. Based on the three-way anti-vibration performance of the actual working environment and To meet the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com