Method for screening cutting performance of composite ceramic cutter with different components

A technology of ceramic cutting tools and cutting performance, applied in image data processing, instruments, electrical digital data processing and other directions, can solve the problems of unreasonable utilization of resources, waste of cutting tool materials, high research and development costs, shorten the design cycle, reduce design costs, Avoid the effect of a large number of cutting experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

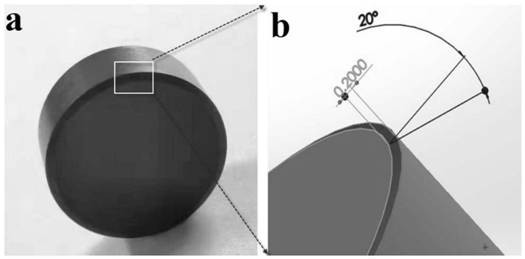

[0039] A method for screening the cutting performance of composite ceramic cutters with different components, comprising the following steps:

[0040] 1) In the material library of Deform-3D software, according to the existing tool material behavior model, input the relevant parameters of ceramic tool materials, and establish ceramic tool material models of different components in the material library of Deform-3D software;

[0041] Since the material library of Deform-3D software does not contain the B required for turning simulation 4 C-TiB 2 Ceramic tool material, therefore applied to B 4 C-TiB 2 Data for ceramic tool materials must be established based on existing tool materials. In the material library of Deform-3D software, Al 2 o 3 Ceramic material is regarded as a rigid tool material whose behavior model is defined by Power's law and described by Eq. (1).

[0042]

[0043] in is the flow stress, is the effective plastic strain, is the effective strain ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com