Distributed kitchen garbage recycling system based on Internet of things

A technology for kitchen waste, recycling and processing, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of reduced transportation efficiency, low efficiency, and environmental pollution, and achieve the effect of facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

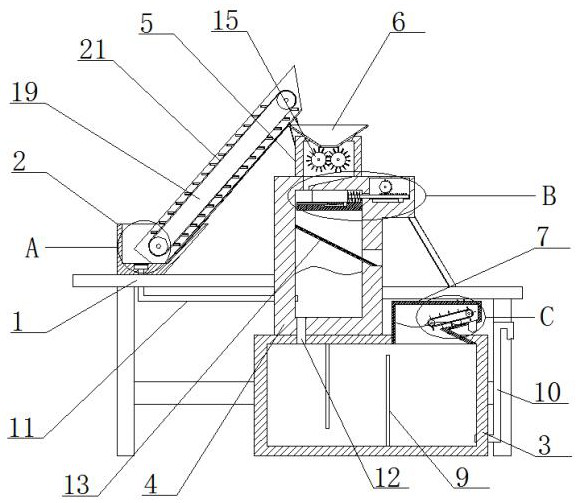

Embodiment 1

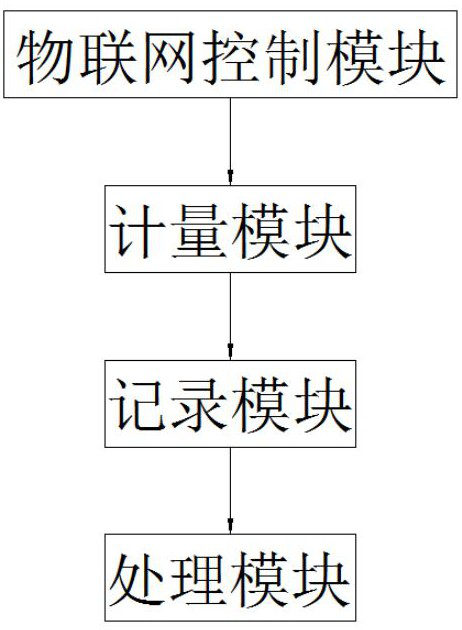

[0030] refer to Figure 1-8, a decentralized food waste recycling and processing system based on the Internet of Things, including an Internet of Things control module, a metering module, a recording module and a processing module connected in sequence, the processing module includes a fixed frame 1, and a feeding shell is arranged on the fixed frame 1 2. There is a lifting mechanism in the feeding shell 2, and a water-oil separation shell 3 and a compression shell 4 are set in the fixed frame 1. The compression shell 4 is set on the top of the water-oil separation shell 3, and the compression shell 4 The top of the crushing shell 5 is provided with a crushing shell 5, the top of the crushing shell 5 is provided with a feed hopper 6, and the crushing shell 5 is provided with a crushing mechanism, the compression shell 4 is provided with a compression mechanism, and the water-oil separation shell 3 The top is provided with a connection case 7, the connection case 7 is connected...

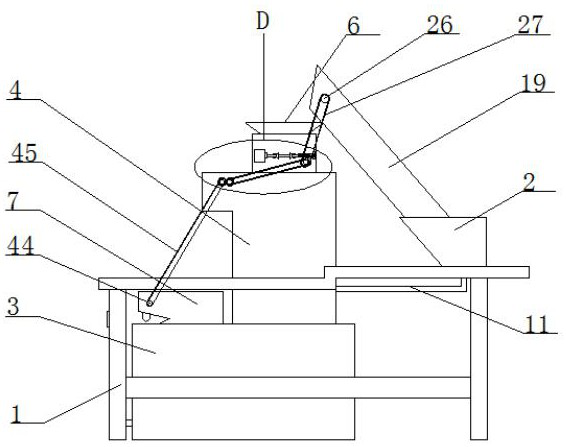

Embodiment 2

[0040] The difference from Embodiment 1 is that it includes an Internet of Things control module, a metering module, a recording module and a processing module connected in sequence, the processing module includes a fixed frame 1, and the fixed frame 1 is provided with a feeding casing 2, and the feeding casing 2 A lifting mechanism is arranged inside, a water-oil separation shell 3 and a compression shell 4 are set inside the fixed frame 1, the compression shell 4 is set on the top of the water-oil separation shell 3, and the top of the compression shell 4 is provided with a crushing shell body 5, the top of the crushing shell 5 is provided with a feed hopper 6, and a crushing mechanism is provided in the crushing shell 5, a compression mechanism is provided in the compression shell 4, and a connecting shell is provided on the top of the water-oil separation shell 3. 7. An oil outlet pipe 8 is connected to the connecting shell 7, and an oil scraping mechanism is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com