Single-layer steel wire rope reel with rope disorder prevention judgment device

A technology of a wire rope reel and a judgment device is applied in the field of wire rope reels, which can solve the problems of inconvenient operation by drivers and high monitoring costs, and achieve the effects of ensuring the accuracy of system monitoring and improving system security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

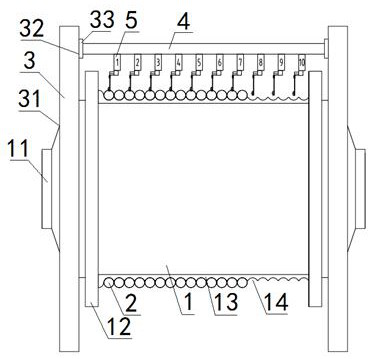

[0042] A single-layer steel wire rope reel with an anti-chaos rope judging device, the reel includes: a drum 1, a steel wire rope 2, two bearing seats 3 arranged in parallel, a limit switch installation rod 4 and a plurality of rocker-type limit switches. Position switch 5; the drum 1 is a cylindrical drum structure, and a steel wire rope 2 is tightly wound on the peripheral surface of the drum 1, and the drum 1 is arranged between two bearing seats 3, and the two ends of the drum 1 are respectively Rotately cooperate with the bearing seat 3 on the corresponding side, one of the bearing seats 3 is fixedly connected to the other bearing seat 3 through a limit switch installation rod 4, the limit switch installation rod 4 is arranged parallel to the central axis of the drum 1, The middle part of the limit switch installation rod 4 is provided with a plurality of rocker-type limit switches 5, and the rocker-type limit switches 5 are arranged near the winding area of the steel wi...

Embodiment 2

[0044] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0045] The distance between the two adjacent rocker-arm type limit switches 5 is equal to the diameter of the wire rope 2 which is an arbitrary integer multiple.

Embodiment 3

[0047] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0048] A scale 34 is also provided on the side far from the roller 1 of the bearing housing 3 , the top of the scale 34 is flush with the top of the chute 32 , and the length of the scale 34 is equal to the length of the chute 32 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com