Rear-mounted precise speed changing and gear shifting device based on line transmission

A shift device, rear-mounted technology, applied in the direction of bicycle gear shifting mechanism, transportation and packaging, bicycle accessories, etc., can solve problems such as stuck, accuracy error, etc., achieve large fault tolerance value, shorten wire rope transmission distance, and avoid accuracy errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

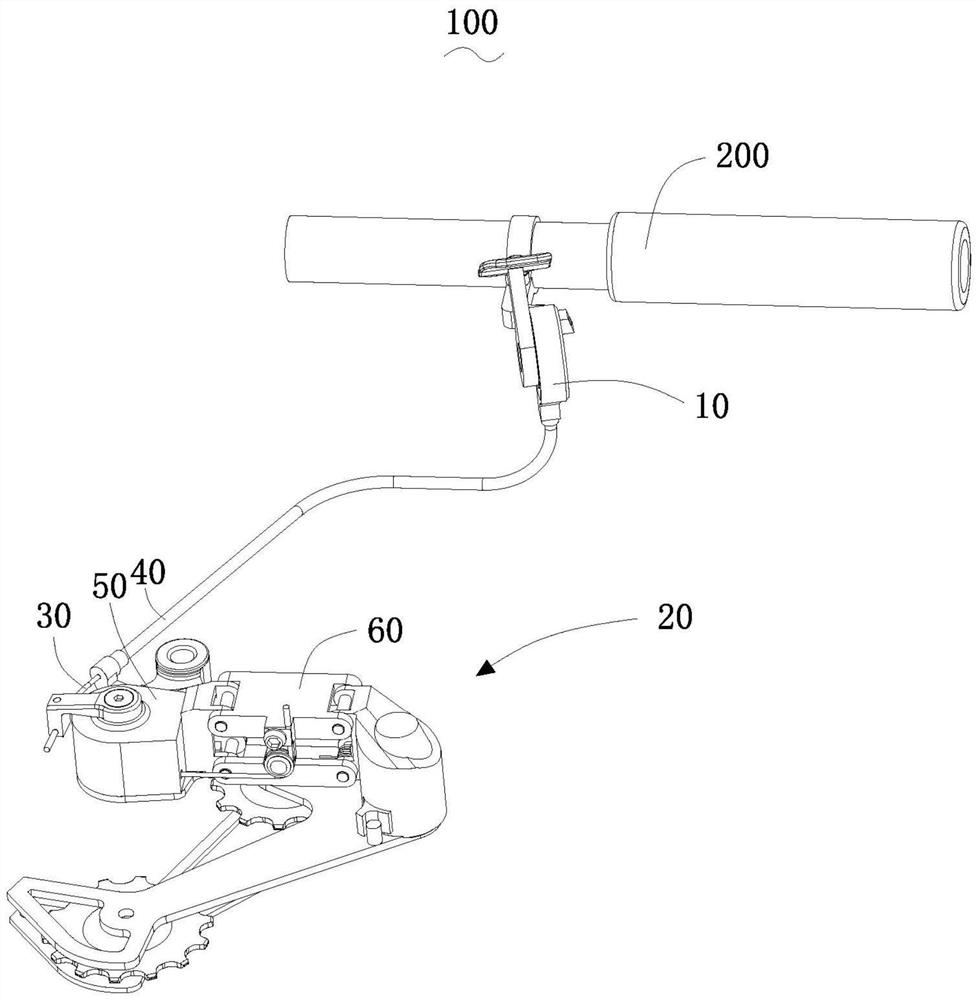

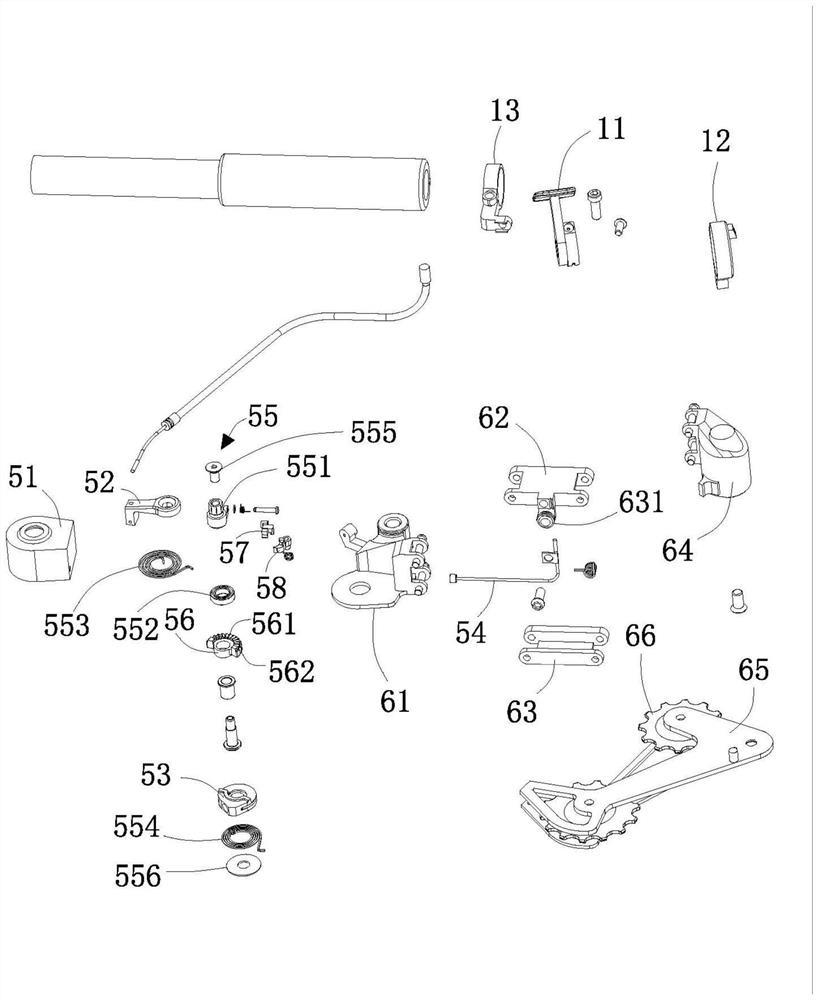

[0019] see Figure 1-Figure 5 , the present embodiment provides a rear-mounted precision gearshift device 100 based on wire transmission, and the device 100 includes a finger shifter 10 , a gear shift mechanism 20 , a wire rope 30 , and a wire rope protection sleeve 40 .

[0020] Specifically, the finger shifter 10 is installed on the bicycle handle 200 . The shift mechanism 20 is installed on the bicycle rear wheel. One end of the wire rope 30 is connected to the finger shifter 10 , and the other end of the wire rope 30 is connected to the shift mechanism 20 .

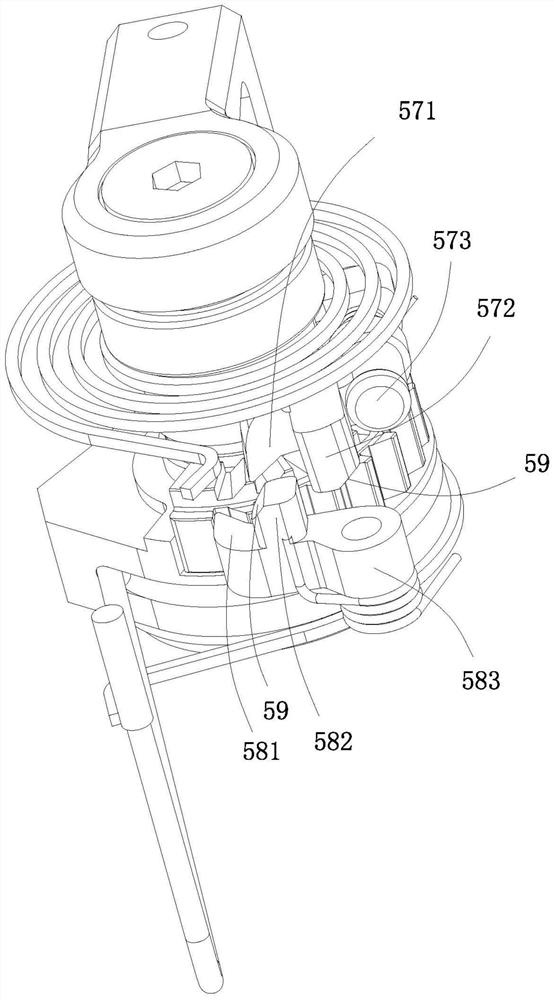

[0021] Specifically, the shift mechanism 20 includes a shifter 50 and a transmission 60 .

[0022] Specifically, the gear shifter 50 is connected to the wire rope 30, and the transmission 60 is connected to the gear shifter 50. When the user toggles the finger shifter 10, the wire rope 30 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com