Tool for forming surface features on workpiece

A technology of surface features and tools, applied in the field of gear transmission equipment, can solve the problems of inconvenient opposite processing, inability to achieve asynchronous symmetrical processing, dislocation production settings, etc., and achieve the effect of facilitating opposite processing and convenient processing and production operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

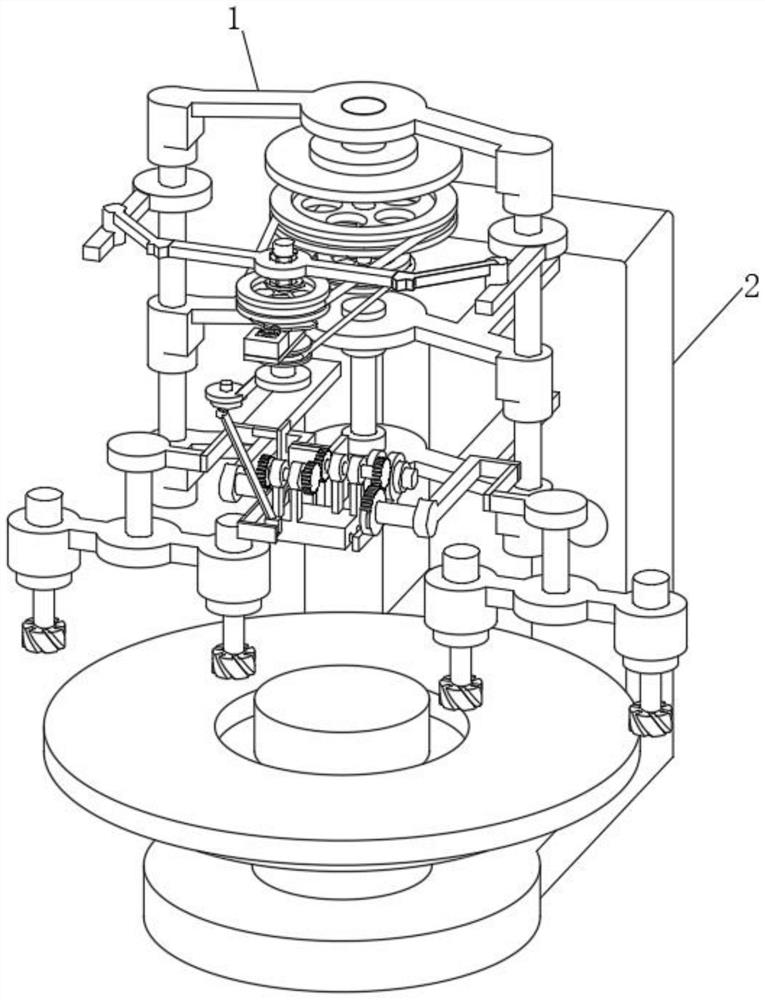

[0031] see Figure 1-8 , the present invention provides a technical solution: a tool for forming surface features on a workpiece, including a pressing driving device 1, the rear end of the pressing driving device 1 is fixedly connected with a mounting and stabilizing device 2, and by installing the pressing driving device 1, Pressing the inner end of the driving device 1 can realize the rotation of multiple parts and realize the continuous transmission of power. At the same time, specific processing tasks can be performed through the first processing part 5 and the second processing part 6 at the inner end, and the setting of the limiting part 4 can be combined with The active part 3 cooperates to realize the regulation of the movement range, meets the needs of different gear processing, and facilitates the adjustment of the height and position of the tooth shape in the production of the gear. The production setting facilitates the phenomenon of opposite processing. Due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com