Robot sorting system and method with flexible feeding mechanism, terminal and medium

A robot system and feeding mechanism technology, applied in the field of intelligent robots, can solve problems such as complicated operation, irregular shape of parts, and difficult selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

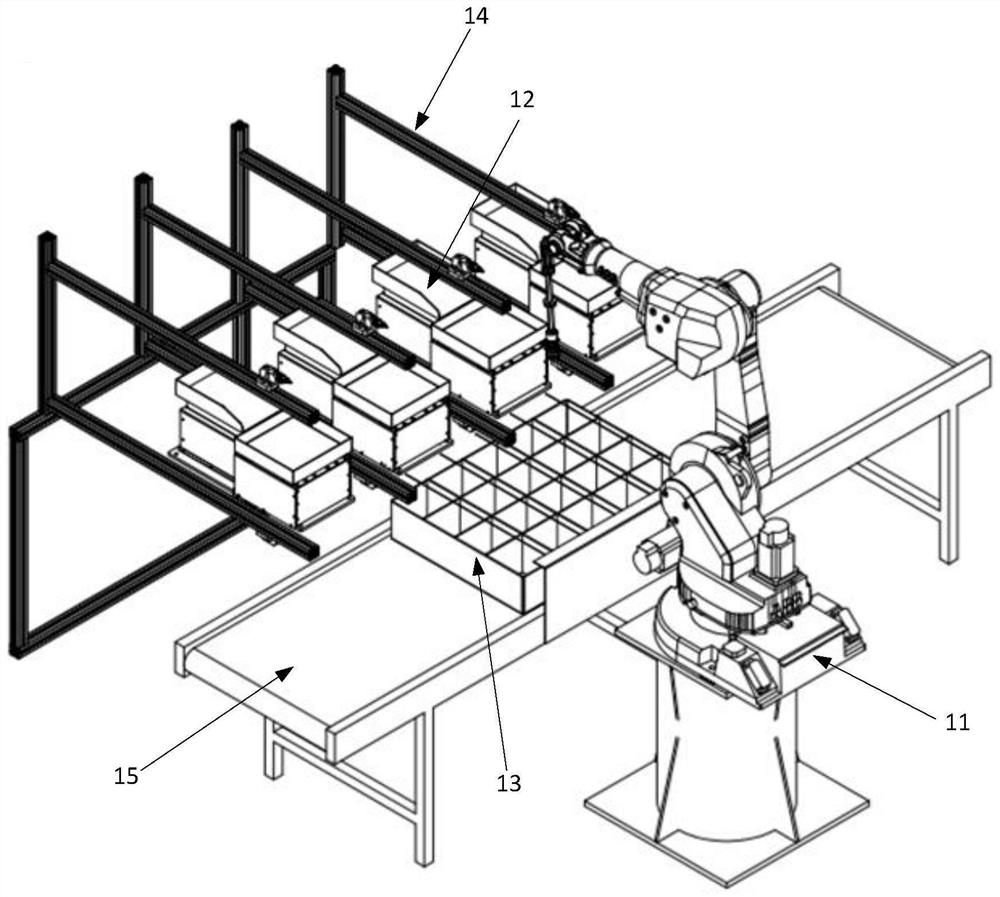

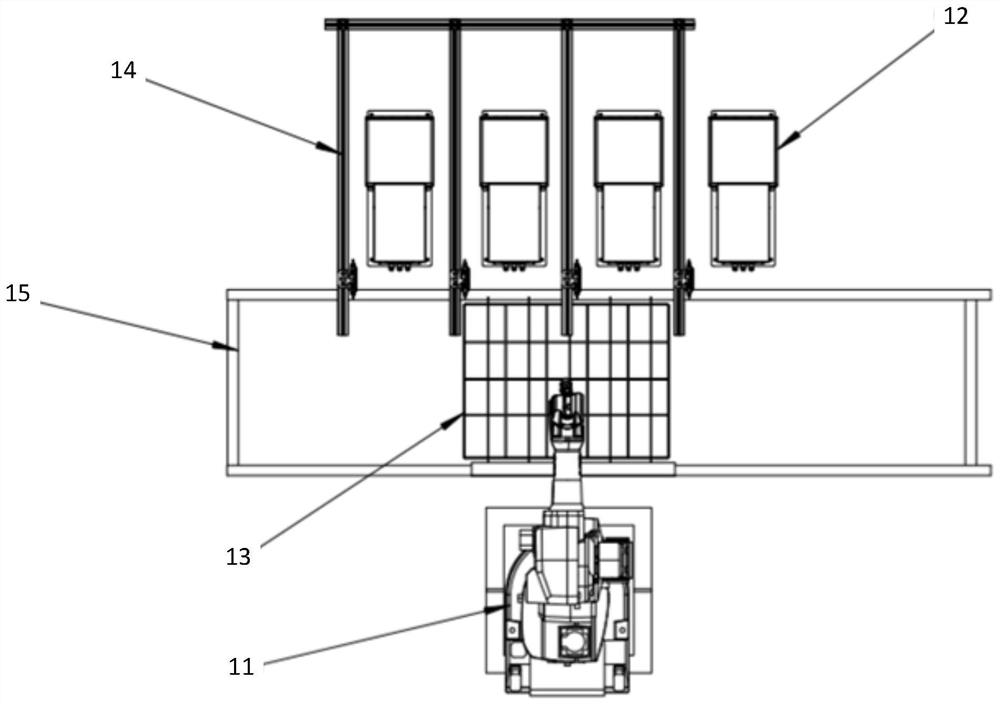

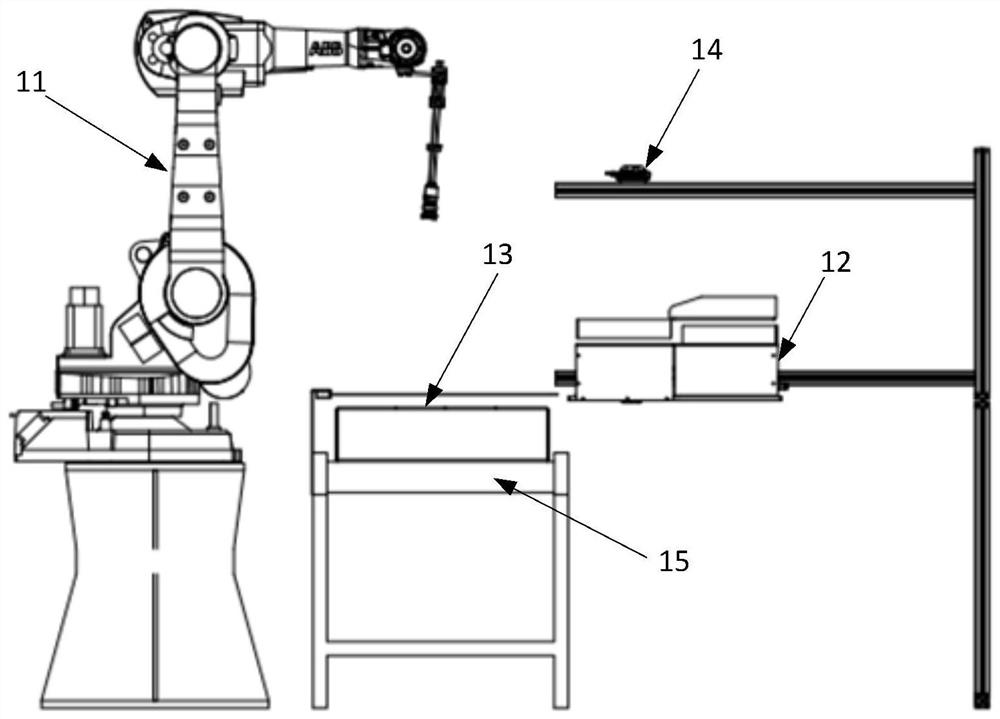

[0040] Such as Figure 1A ~ 1C As shown, a schematic structural view of a robot sorting system with a flexible feeding mechanism in an embodiment of the present invention is shown. Figure 1A Shown is a perspective view of the robot sorting system; Figure 1B Shown is the top view of the robot sorting system; Figure 1C Shown is a side view of a robotic sorting system. The robot sorting system of this embodiment includes a robot system 11, a flexible feeding mechanism 12, a material receiving mechanism 13, a vision system 14, a conveying system 15, a grabbing and quick-changing system (not shown), and the robots will be sorted below The various institutions and systems in the system are explained in detail.

[0041] In some examples, the flexible feeding mechanism 12 is used to rearrange the parts and materials accumulated together from the upstream equipment, and convert the 3D posture into 2D or 2.5D limited postures. In this embodiment, the flexible feeding mechanism 12 ...

Embodiment 2

[0059] Such as image 3 As shown, a schematic flow chart of the robot sorting method in an embodiment of the present invention is shown. The robot sorting method of this embodiment can be applied to the vision system in the above robot sorting system, and mainly includes the following steps.

[0060] Step S301: Obtain an image of the part material in the flexible feeding mechanism, and extract the visual information of the part material from the image. Wherein, the part material visual information includes but not limited to position information, posture information, specification information, size information and the like.

[0061] Step S302: Judging whether each part material meets the picking requirement according to the visual information of the part material and determining the type of the end effector of the robot system.

[0062] In some examples, the conditions that parts and materials meet the picking requirements include but are not limited to not stacking parts an...

Embodiment 3

[0067] Such as Figure 4 As shown, a schematic structural diagram of an electronic terminal in an embodiment of the present invention is shown. The electronic terminal provided by this example includes: a processor 41, a memory 42, and a communicator 43; the memory 42 is connected to the processor 41 and the communicator 43 through a system bus and completes mutual communication, and the memory 42 is used to store computer programs and communicate The processor 43 is used to communicate with other devices, and the processor 41 is used to run a computer program to make the electronic terminal execute the steps of the robot sorting method above.

[0068] The system bus mentioned above may be a Peripheral Component Interconnect (PCI for short) bus or an Extended Industry Standard Architecture (EISA for short) bus or the like. The system bus can be divided into address bus, data bus, control bus and so on. For ease of representation, only one thick line is used in the figure, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com