Method for improving injection molding defects of thermosetting composite material

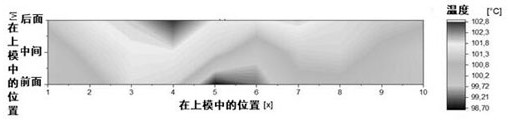

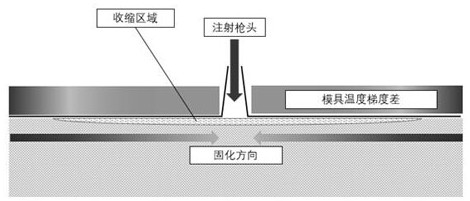

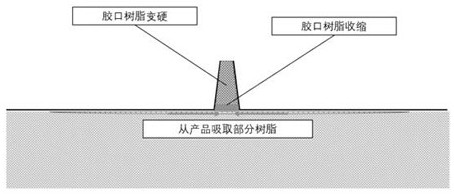

A composite material, injection molding technology, applied in the field of injection molding, can solve problems such as product shrinkage defects, poor mold temperature gradient, low temperature, etc., to improve injection molding defects, improve product molding quality, and improve the effect of apparent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method to improve the injection molding defects of thermosetting carbon fiber aviation aircraft door side beams, the volume of the required molding mold is 6010cm through 3D model calculation 3 .

[0024] Use Araldite® LY 3585 epoxy resin as component A, and Aradur® 3475 epoxy resin as component B. Mix components A and B in proportion to a mixed density of 1.1g / cm 3 mixed resin, as injection resin.

[0025] According to the product of the resin density and 0.45 times the volume of the molding mold, the total amount of epoxy resin required for debugging is 2975g, and then injected. All 2975g of mixed resin is injected at a flow rate of 50g / s into the molding machine preheated to the molding temperature of 110°C. In the mold, it was cured at a constant temperature for 270s, and the mold was opened. The surface of the obtained thermosetting carbon fiber aircraft door side beam had obvious shrinkage defects.

Embodiment 2

[0027] The difference from Example 1 is that 2800g of mixed resin (accounting for 94.2% of the total mass of the resin) is injected at a flow rate of 50g / s into a molding mold preheated to a molding temperature of 110°C, treated at a constant temperature for 60s, and then secondly injected , that is, 175g of mixed resin is continuously injected into the molding mold at a flow rate of 50g / s, and continues to cure for 270s. After curing and molding, the mold is opened. The shrinkage defect of the injection port area of the obtained thermosetting carbon fiber aircraft door side beam is improved compared with one-time injection molding.

Embodiment 3

[0029] The difference from Example 1 is that 2850g of mixed resin (accounting for 95.8% of the total mass of the resin) is injected at a flow rate of 50g / s into a molding mold preheated to a molding temperature of 110°C, treated at a constant temperature for 60s, and then performed a second injection , is about to continue to inject 125g mixed resin in the molding mold with the flow velocity of 50g / s, continue to solidify 270s, mold is opened after curing and molding, the shrinkage defect of the injection port area of the obtained thermosetting carbon fiber aircraft door side beam still exists, but compares embodiment 2 has improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com