Battery cell tab and battery cell

A technology of tabs and batteries, applied to circuits, electrical components, battery pack components, etc., can solve problems such as the mismatch between the size and the energy of the batteries, and achieve reduced packaging reliability exploration, reduced welding process exploration, and large area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

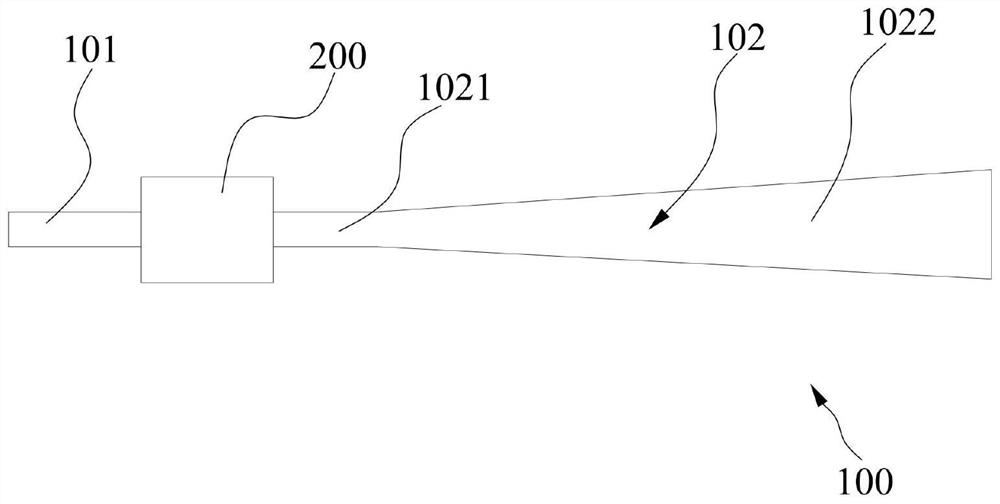

[0031] Such as figure 1 As shown, this embodiment provides a battery tab, including a tab body 100 and a tab glue 200 . The tab body 100 passes through the tab glue 200. The tab body 100 includes a short side 101 and a long side 102. The short side 101 is connected to the long side 102. The short side 101 extends out of one end of the tab glue 200, and the long side 102 extends out The end of the ear glue 200 away from the short side 101 , the thickness of the end of the long side 102 close to the ear glue 200 is smaller than the thickness of the end of the long side 102 away from the ear glue 200 .

[0032] The battery tab provided in this embodiment, by setting the tab body 100 and the tab glue 200, the short side 101 of the tab body 100 protrudes from one end of the tab glue 200, and the long side 102 extends out of the tab glue 200 away from the short side. At one end of the side 101, the thickness of the end of the long side 102 close to the ear glue 200 is smaller than ...

Embodiment 2

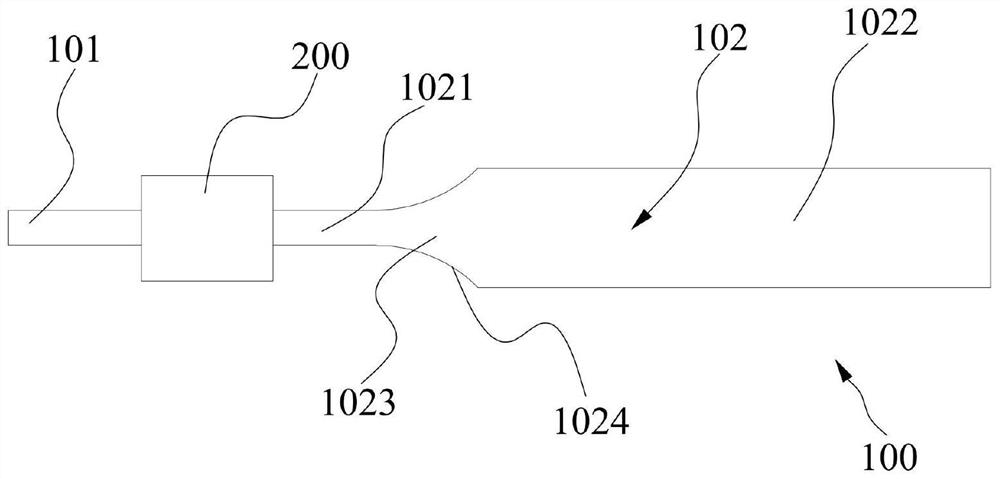

[0037] Such as figure 2 As shown, this embodiment provides a cell lug, which is different from Embodiment 1 in that a transition section 1023 is provided between the connecting section 1021 and the thickened section 1022 , and the transition section 1023 is provided with a transition arc 1024 . By setting the transition section 1023 with the transition arc 1024, the thickness increase from the connecting section 1021 to the thickening section 1022 is smoother, which is convenient for transportation and storage of the battery lug, and can prevent scratches, and the structure of the tab body 100 The stability is improved, ensuring the service life of the tab body 100 , and at the same time ensuring the overcurrent capability of the battery tab, increasing the heat dissipation area, and reducing the temperature rise of the tab body 100 .

[0038] Optionally, the radius of the transition arc 1024 is 1 mm to 10 mm, the thickness of the short side 101 is 0.2 mm to 0.6 mm, and the t...

Embodiment 3

[0040] This embodiment provides a battery cell, including the battery cell lug of the above embodiment, wherein the short side 101 is welded to the foil drawn from the pole piece, and the tab glue 200 is packaged and sealed with an aluminum-plastic film.

[0041] For the cell provided in this embodiment, the thickness of the short side 101 and the ear glue 200 are kept constant, and the long side 102 is set in a special shape, and the thickness of the long side 102 is increased. The edge is not easy to heat up to the limit temperature, and the overall conductivity of the battery cell is strong, which improves the overall conductivity of the battery cell, reduces tedious welding process exploration, does not need to replace packaging tooling and processes, reduces packaging reliability exploration, and saves time and cost. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com