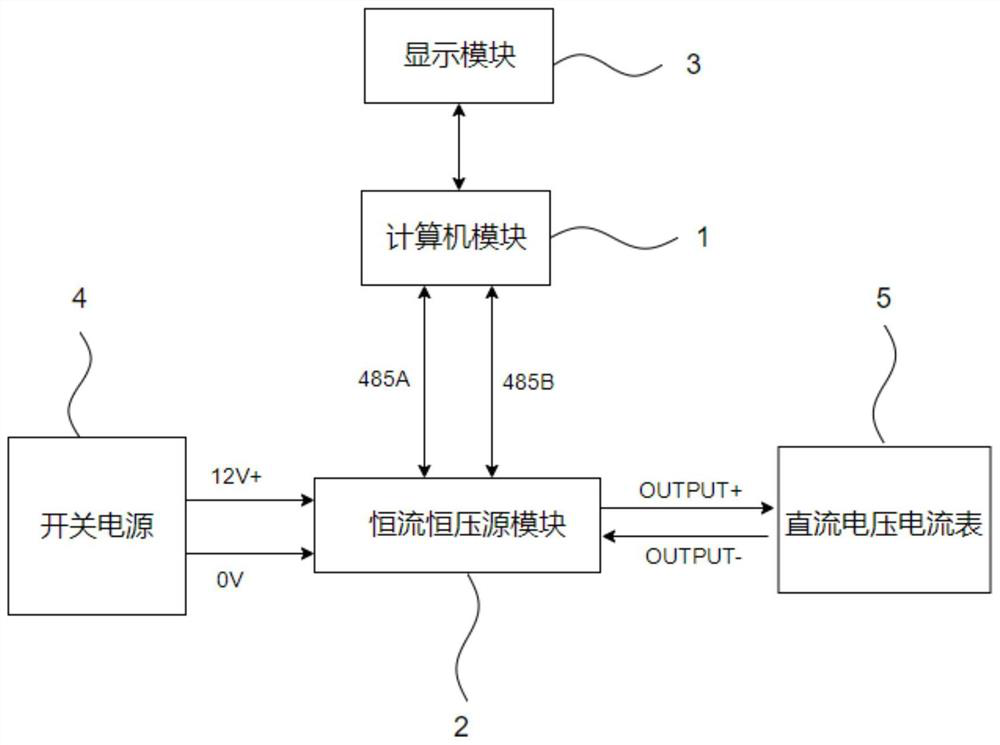

Direct-current volt-ammeter calibration device and calibration method

A technology of DC voltage and calibration device, applied in measuring devices, measuring electrical variables, instruments, etc., can solve the problem of unable to drive the pointer ammeter, etc., and achieve the effect of light weight, small size and strong driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

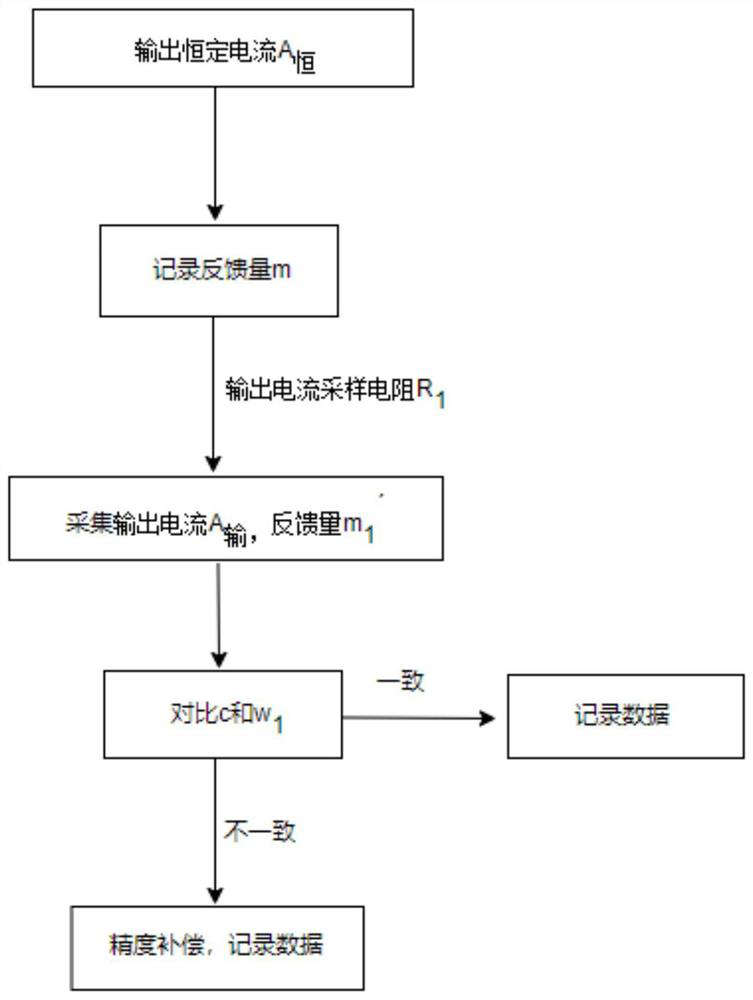

[0034] Such as figure 2 Shown, a DC ammeter calibration method, including the following steps:

[0035] S 1 : Turn on the switching power supply to provide a current and voltage source for the constant current and constant voltage source module, and then the computer module sends an instruction to the constant voltage and constant current source module through the 485 protocol to output a constant current A 恒 ;

[0036] S 2 : Set the ideal calibration coefficient c=1, record the feedback m of the ammeter to the display module at this time, and then output a current sampling resistor R 1 , put the output current A 输 Sampling back, record the feedback m of the ammeter to the display module at this time 1 ′, forming negative feedback, the formula of the computer module is as follows:

[0037] where R is (R 1 , R 2 , R 3 ...), m 1 ', A 输 , Change with the change of R.

[0038] S 3 : match c with w 1 For comparison, the computer module finally sends data through th...

Embodiment 2

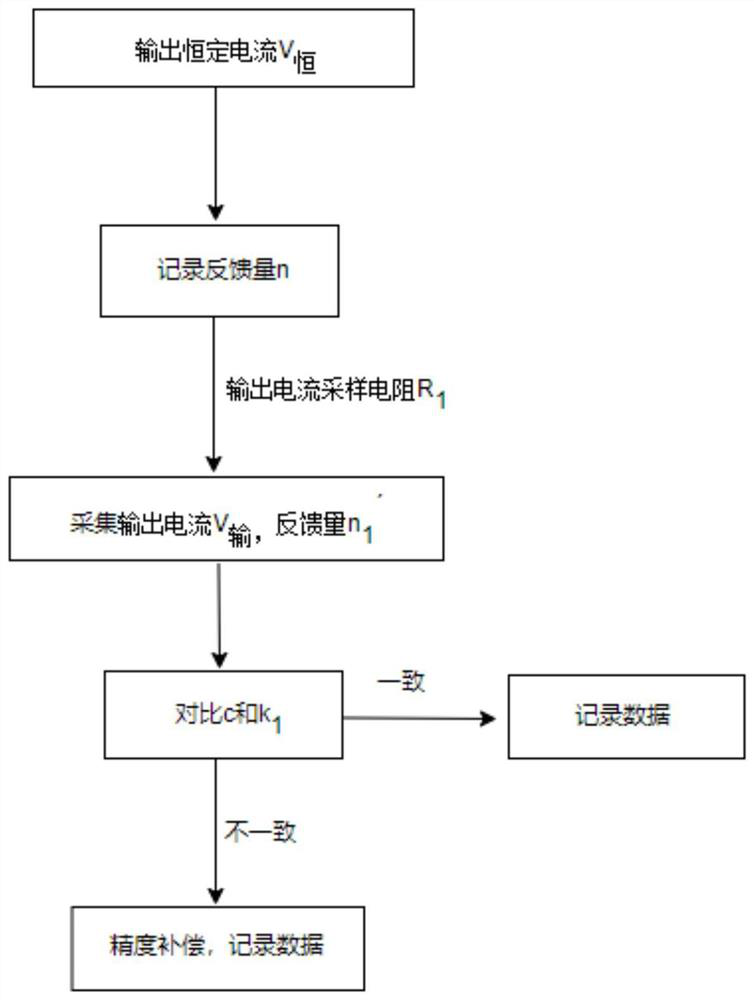

[0040] Such as image 3 As shown, a DC voltmeter calibration method includes the following steps:

[0041] S 1 : Turn on the switching power supply to provide a current and voltage source for the constant current and constant voltage source module, and then the computer module sends an instruction to the constant voltage and constant current source module through the 485 protocol to output a constant voltage V 恒 ;

[0042] S 2 : Set the ideal calibration coefficient c=1, record the feedback amount n that the voltmeter feeds back to the display module at this time, and then output a current sampling resistor R 1 , put the output voltage V 输 Sampling back, record the feedback amount n of the voltmeter to the display module at this time 1 ′, forming negative feedback, the formula of the computer module is as follows:

[0043] where R is (R 1 , R 2 , R 3 ...), n ′ and V 输 Varies with R.

[0044] S 3 : combine c with k 1 For comparison, the computer module finally sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com