Device for detecting axial force of hub and displacement of bearing in real time by applying torque

A technology of real-time detection and axial force, applied in measuring devices, wheel testing, instruments, etc., can solve the problem of setting process parameters based on experience, and achieve the effect of ensuring assembly consistency, high flexibility, and scientific process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

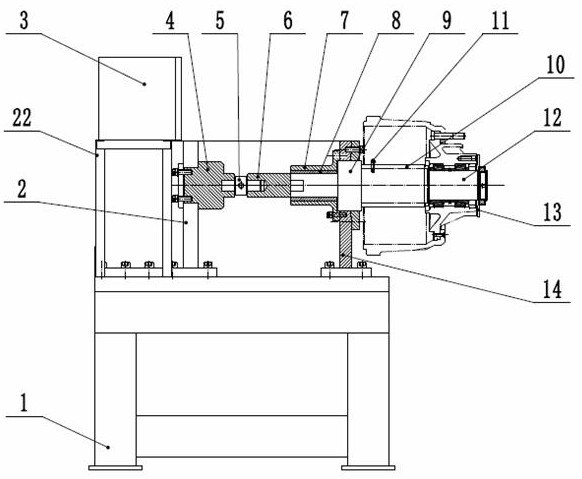

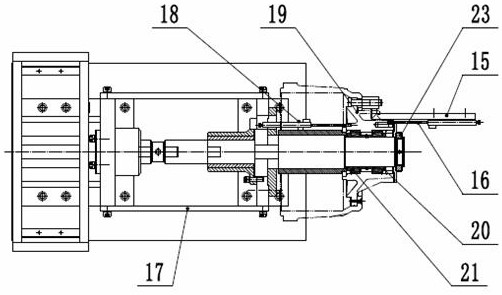

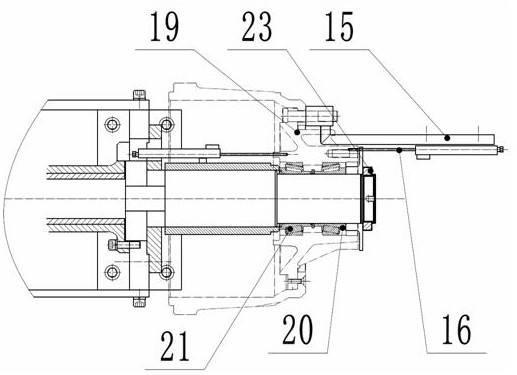

[0020] For better understanding and implementation, specific embodiments are given below in conjunction with the accompanying drawings to describe the present invention in detail. The given embodiments are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

[0021] Such as figure 1 , 2 As shown in , 3, a device for real-time detection of wheel hub axial force and bearing displacement by applying torque, including a frame 1, a load-bearing seat 2, a support seat 14, and a process monitoring instrument mounting bracket 22 are fixedly installed on the table surface of the frame 1 ; In order to ensure the rigidity of the system, the bearing base 2 is fixed as a whole with the connecting plate 17 between the bearing base 14; the pressure sensor base 4 is installed on the bearing base 2, and the pressure sensor is connected to each other. One end of the transition sleeve 6 is connected;

[0022] The guide sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com