Double-anchoring and double-packing tie-back system for staged fracturing string

A technology of staged fracturing and pipe string, applied in the directions of sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problems of complex structure, poor sealing and reliability of the return pipe string, and achieve the risk of occurrence The effect of low probability, simple operation, convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

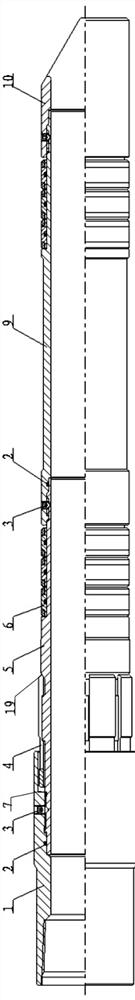

[0033] refer to Figure 1-Figure 6 As shown, a double-anchored double-package tieback system for staged fracturing strings includes a first tieback plug 11 , a tieback barrel 12 and a second tieback plug 15 .

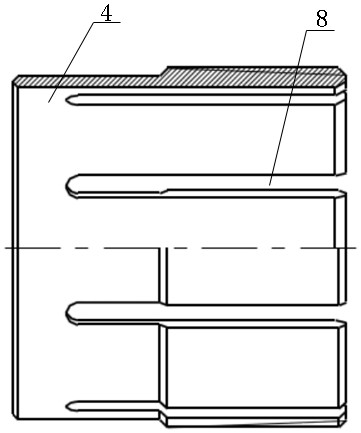

[0034] Wherein, a first anchoring device is provided on the first tie-back plug 11, and the first anchoring device includes locking slips 4, and one end of the locking slips 4 is provided with a plurality of one-end openings to form simply supported beams. The locking groove 8 of the structure, through the locking groove 8, the locking slip 4 can be deformed when it is plugged into the tie-back barrel 12, which is convenient for entering the tie-back barrel 12. There is also a set on the locking slip 4 Self-locking male buckle.

[0035] On the inner wall of the connecting cylinder 12, there is a self-locking female buckle matched with the self-locking male buckle, so that when the locking slip 4 enters the connecting cylinder 12 through the deformation of the locking g...

Embodiment 2

[0039] A double-anchored double-package tieback system for staged fracturing strings, comprising a first tieback plug 11 , a tieback barrel 12 and a second tieback plug 15 .

[0040] Wherein, a first anchoring device is provided on the first tie-back plug 11, and the first anchoring device includes locking slips 4, and one end of the locking slips 4 is provided with a plurality of one-end openings to form simply supported beams. The locking groove 8 of the structure, through the locking groove 8, the locking slip 4 can be deformed when it is plugged into the tie-back barrel 12, which is convenient for entering the tie-back barrel 12. There is also a set on the locking slip 4 Self-locking male buckle.

[0041] On the inner wall of the connecting cylinder 12, there is a self-locking female buckle matched with the self-locking male buckle, so that when the locking slip 4 enters the connecting cylinder 12 through the deformation of the locking groove 8, the self-locking female buckl...

Embodiment 3

[0046] A double-anchored double-package tieback system for staged fracturing strings, comprising a first tieback plug 11 , a tieback barrel 12 and a second tieback plug 15 .

[0047] Wherein, a first anchoring device is provided on the first tie-back plug 11, and the first anchoring device includes locking slips 4, and one end of the locking slips 4 is provided with a plurality of one-end openings to form simply supported beams. The locking groove 8 of the structure, through the locking groove 8, the locking slip 4 can be deformed when it is plugged into the tie-back barrel 12, which is convenient for entering the tie-back barrel 12. There is also a set on the locking slip 4 Self-locking male buckle.

[0048] On the inner wall of the connecting cylinder 12, there is a self-locking female buckle matched with the self-locking male buckle, so that when the locking slip 4 enters the connecting cylinder 12 through the deformation of the locking groove 8, the self-locking female buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com