Integrated water tank

A technology for sinks and chopping boards, which can be used in water supply installations, indoor sanitary plumbing installations, household appliances, etc., and can solve problems such as contamination of the countertops on the back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

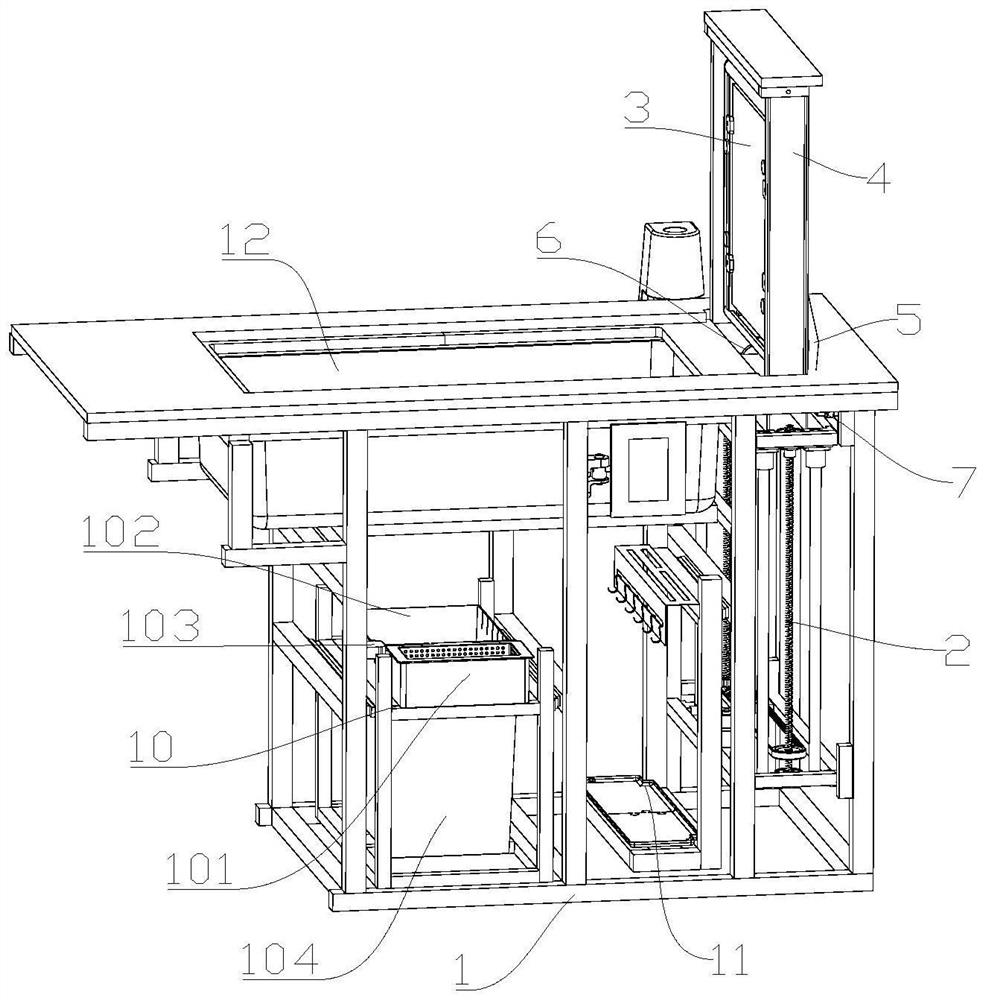

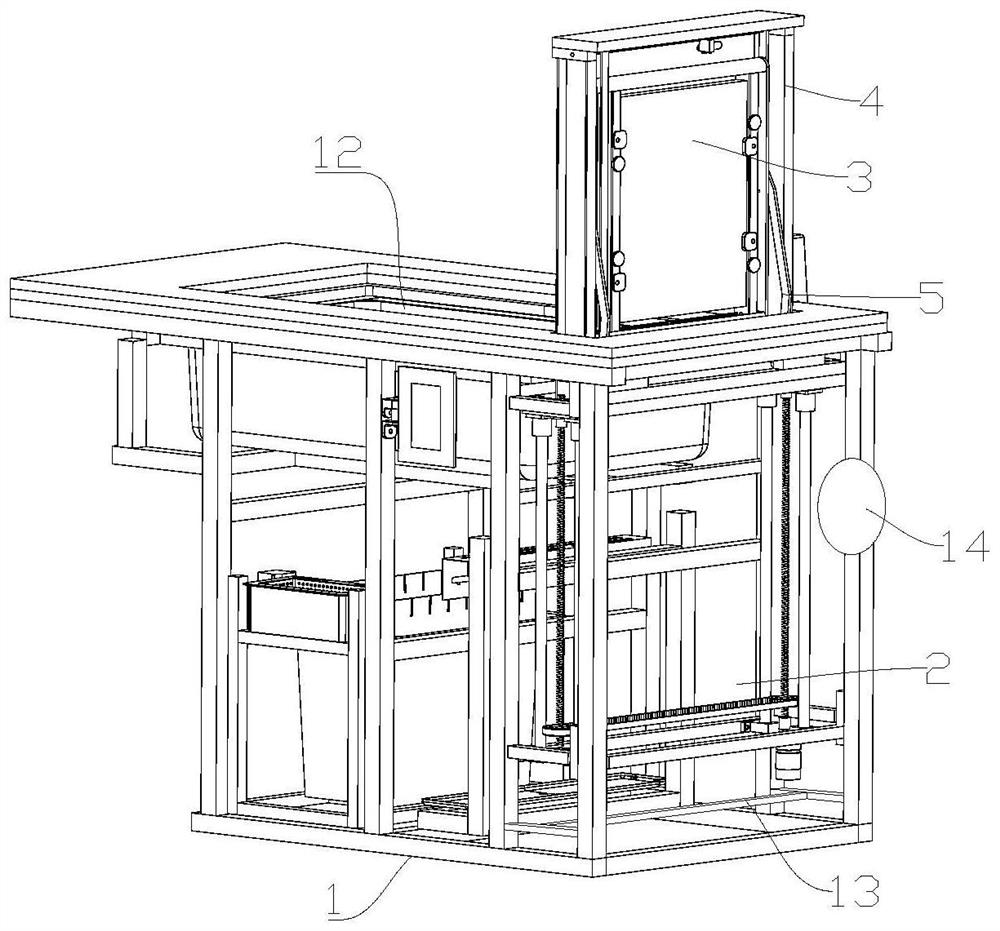

[0040] Such as Figure 1-10 As shown, this embodiment provides an integrated sink, including a sink support frame 1, a chopping board turning device and a connecting rod limit assembly 7; the chopping board turning device includes a lifting device 2, a chopping board component 3, a frame 4, and a connecting rod component 5 and a drive assembly 6 for driving the forward and reverse rotation of the above-mentioned chopping board assembly 3, the above-mentioned connecting rod assembly 5 is rotationally connected with the above-mentioned chopping board assembly 3, the above-mentioned connecting rod assembly 5 is rotationally connected with the frame 4, and the above-mentioned connecting rod assembly 5 is connected with the above-mentioned connecting rod The limiting assembly 7 is rotationally connected; the above-mentioned elevating device 2 is arranged on the above-mentioned tank supporting frame 1, the output end of the above-mentioned elevating device 2 is in transmission connec...

Embodiment 2

[0049] Such as Figure 1-10 As shown, in this embodiment, on the basis of Embodiment 1, the above-mentioned chopping board assembly 3 includes a frame body 31, a chopping board 32, a clamping assembly 33 and two clamping brackets 34, any one of the above-mentioned clamping brackets 34 and the above-mentioned frame body 31 Slidingly connected, the above-mentioned chopping board 32 is arranged between two above-mentioned clamping brackets 34, any one of the above-mentioned clamping brackets 34 is connected with the above-mentioned chopping board 32 through the above-mentioned clamping assembly 33;

[0050] In this embodiment, the chopping board 32, the clamping assembly 33 and the two clamping brackets 34 are all located in the frame body 31, the chopping board 32 is installed between the two clamping brackets 34, and then the chopping board 32 is connected to the clamping assembly 33. The two clamping brackets 34 are clamped so that the chopping board 32 can be stably fixed in ...

Embodiment 3

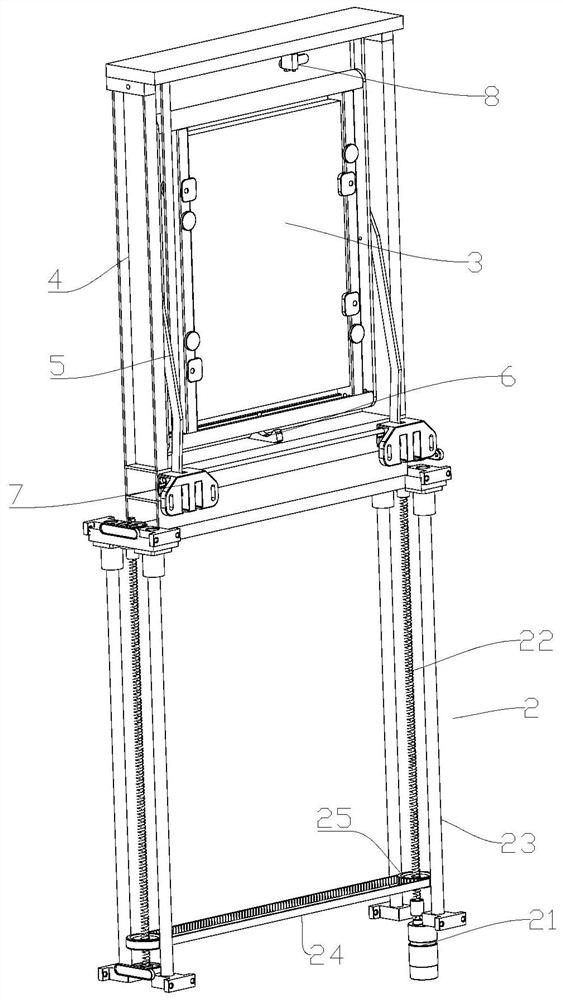

[0055] Such as Figure 1-10 As shown, this embodiment is based on some of the above-mentioned embodiments, the above-mentioned connecting rod assembly 5 includes a first connecting rod 51 and a second connecting rod 52, the first end of the above-mentioned first connecting rod 51, the first end of the above-mentioned second connecting rod 52 One end is rotatably connected to the above-mentioned chopping board assembly 3, the second end of the above-mentioned first connecting rod 51 is rotatably connected to the upper end of the above-mentioned frame 4, and the second end of the above-mentioned second connecting rod 52 is rotatably connected to the above-mentioned connecting rod limiting assembly 7. connected, and the above-mentioned link assembly 5 is detachably connected with the above-mentioned link limit assembly 7.

[0056] In this embodiment, both the first connecting rod 51 and the second connecting rod 52 are rotatably connected with the chopping board assembly 3, drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com