Online split-phase acquisition device and method for Fischer-Tropsch reaction products

A Fischer-Tropsch reaction and collection device technology, applied in measurement devices, analytical materials, material separation, etc., can solve the problems of poor separation effect and high moisture content in the gas phase, and achieve the effects of improving efficiency, high timeliness, and avoiding analysis errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

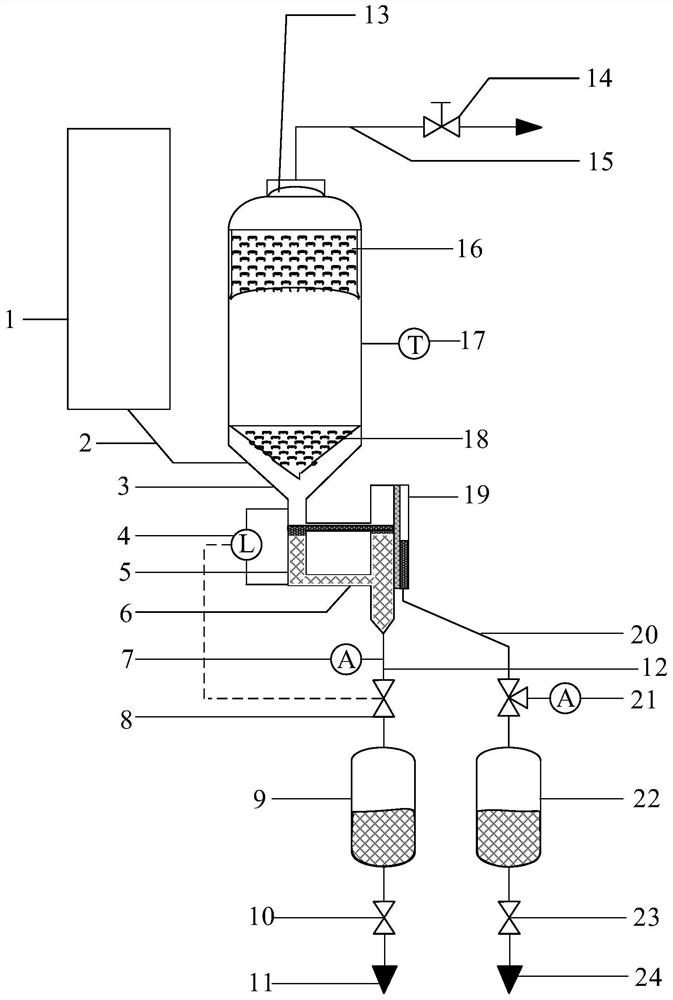

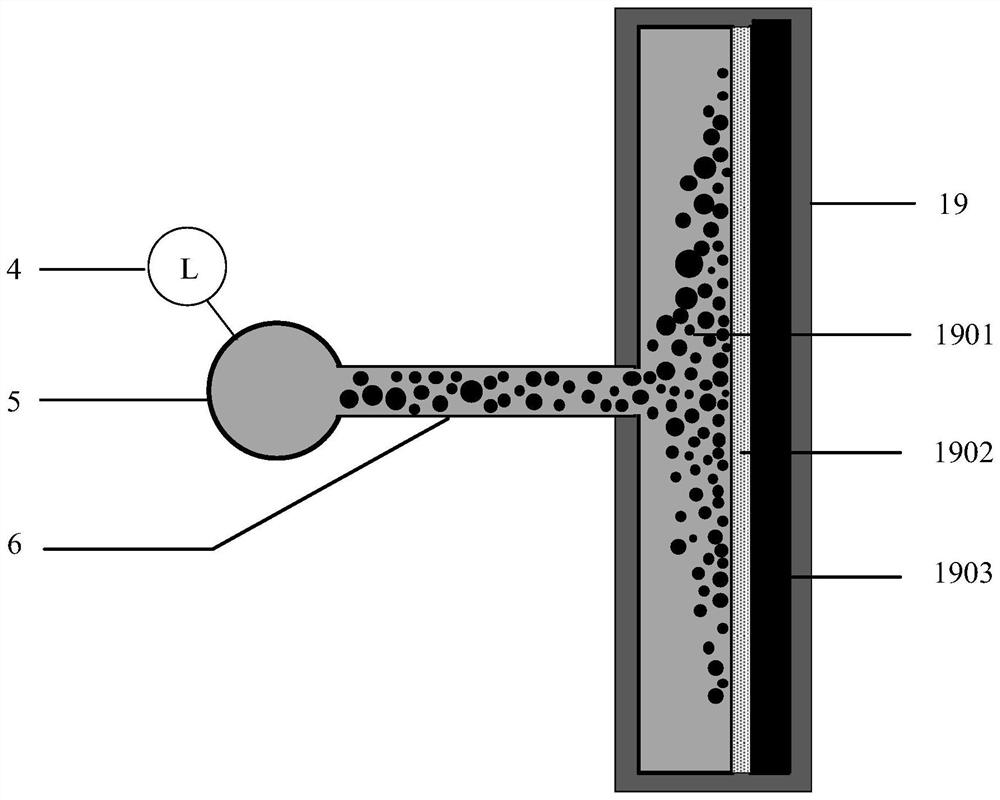

[0080] The on-line phase-separation collection device of the Fischer-Tropsch reaction product used in this embodiment is as follows: figure 1 shown, and the structure of the water-oil separator is as figure 2 shown.

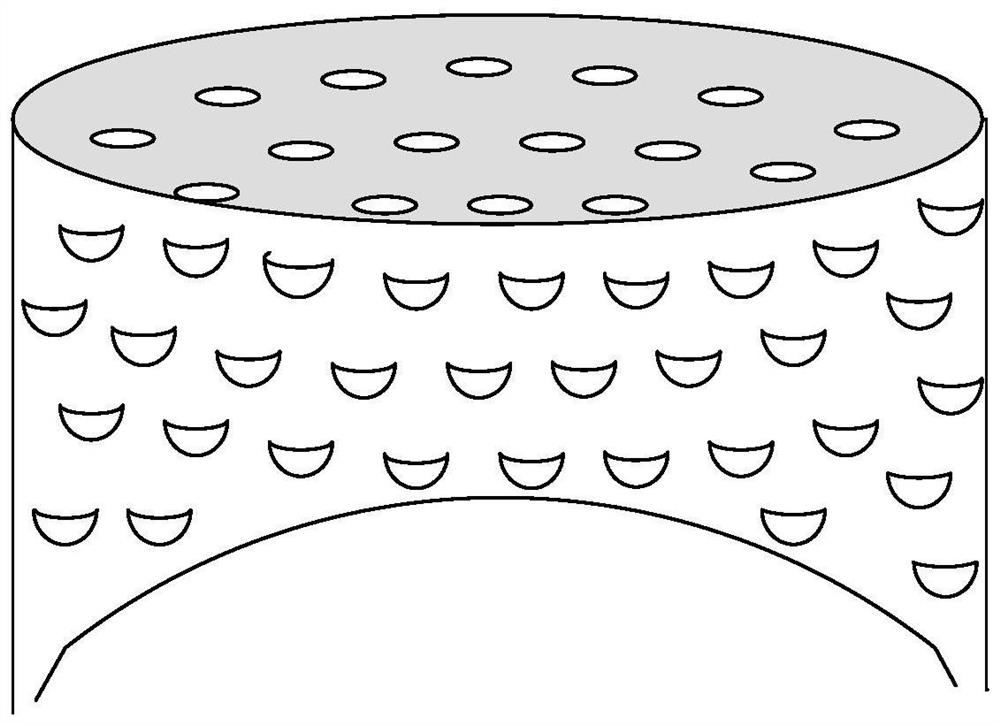

[0081] After the Fischer-Tropsch reaction product flows out of the reactor, it flows into the flash separation tank through the outlet pipeline of the reactor, and in the flash separation tank, it passes through the cone liquid separation plate, the arch liquid separation plate, and the membrane separation module from bottom to top in sequence for flash evaporation Separation, water interception, foam breaking and diversion, separation to obtain gas phase and liquid phase;

[0082] The gas phase is heated and kept at 100°C and sent to the gas chromatograph for real-time analysis of the composition;

[0083] The liquid phase (water-oil mixture) flows into the liquid storage pipe from the outlet of the flash separation tank, and is stratified under the action of...

Embodiment 2

[0097] According to the method of embodiment 1, the difference is that a water-oil separator is not provided.

[0098] Concrete process condition and separation result in the present embodiment are as shown in table 1.

Embodiment 3

[0100] According to the method of embodiment 1, the difference is that no arched liquid separator is provided.

[0101] Concrete process condition and separation result in the present embodiment are as shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com