Free liquid control agent as well as preparation method and application thereof

A control agent and free technology, applied in the direction of chemical instruments and methods, silicates, drilling compositions, etc., can solve the problems of large amount of liquid silicon, reduce the free liquid of cement slurry, etc., and achieve short thickening time, No procoagulant side effects, eliminating or reducing the effect of free fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

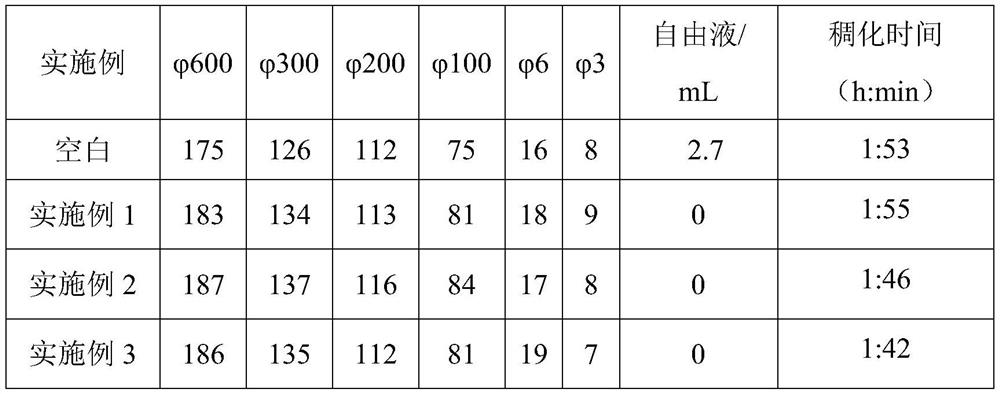

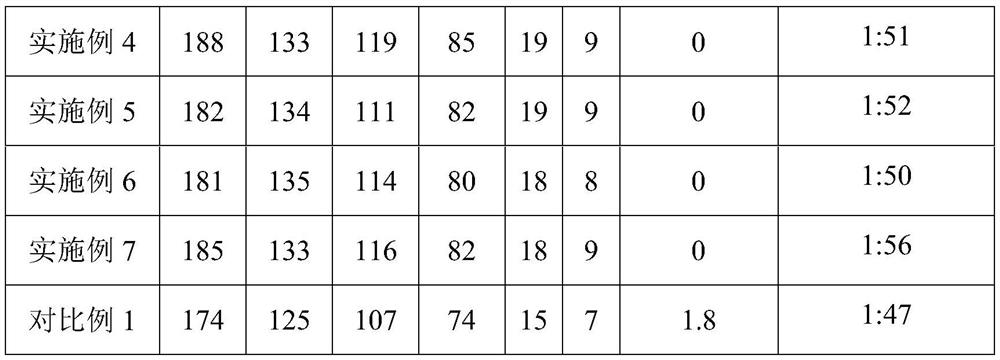

Examples

Synthetic example 1

[0093] With calcium nitrate tetrahydrate and tetraethoxysilane as raw materials, the raw materials are weighed respectively according to the stoichiometric ratio of calcium-silicon molar ratio of 1:1, put into a reaction kettle, and then the mass ratio of water and calcium nitrate tetrahydrate is 10:1 Add distilled water, add calcium nitrate tetrahydrate, tetraethoxysilane and 3 / 10,000 of the catalyst hexamethamine, stir and react in the reaction kettle at 50°C for 5 hours to obtain calcium silicate hydrate liquid Product A.

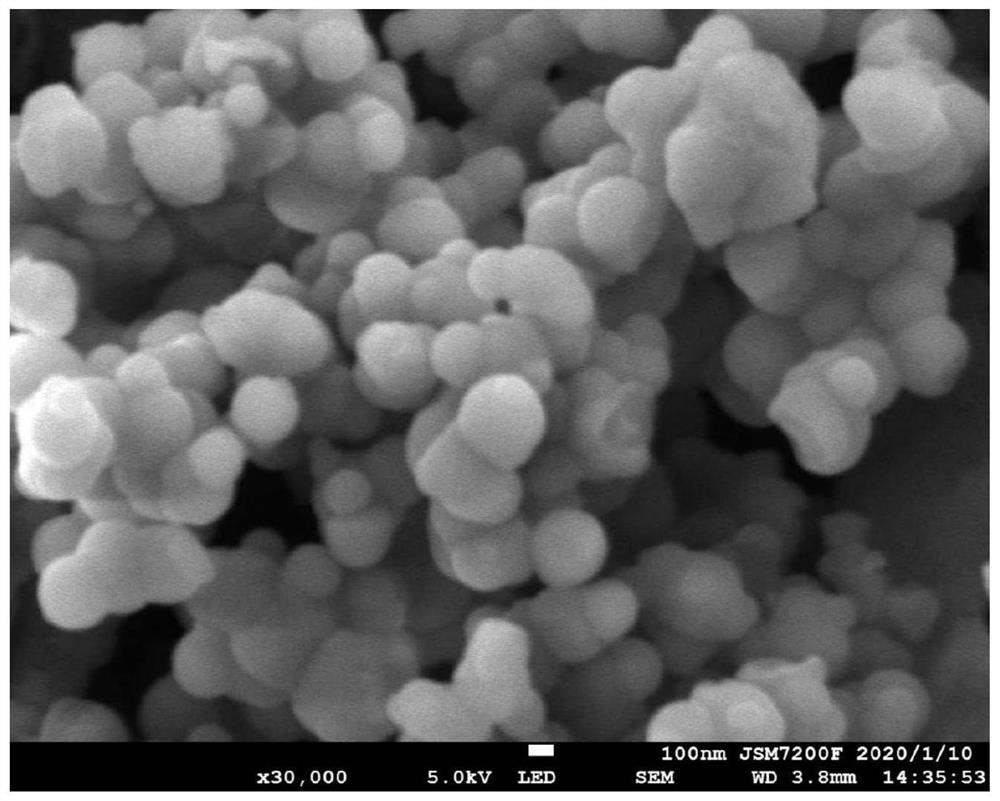

[0094] The synthetic calcium silicate hydrate liquid product A was processed, specifically, pouring 1 part of the synthesized liquid product sample into 5 parts of absolute ethanol, ultrasonicating for 3 minutes, and filtering; after repeating three times. Pour 1 part of the sample into 5 parts of absolute ethanol again, ultrasonicate for 3 minutes, suck it out with a dropper and drop it on the aluminum foil, and dry it at 90°C for later use to prepare a...

Synthetic example 2

[0096] The preparation method is the same as that of Synthesis Example 1, except that the catalyst is amantadine hydrochloride to obtain calcium silicate hydrate liquid product B.

Synthetic example 3

[0098] The preparation method is the same as that of Synthesis Example 1, except that the catalyst is a mixture of amantadine hydrochloride and urotropine, wherein the mass ratio of amantadine hydrochloride and urotropine is 1:1 to obtain hydrated silicic acid Calcium liquid product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com