Translation downward-sliding barrel discharging device of particle barrel washing machine

A barrel washing machine and granule technology, which is applied to conveyor control devices, conveyors, slideways, etc., can solve the problems of insufficiency, high failure rate and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

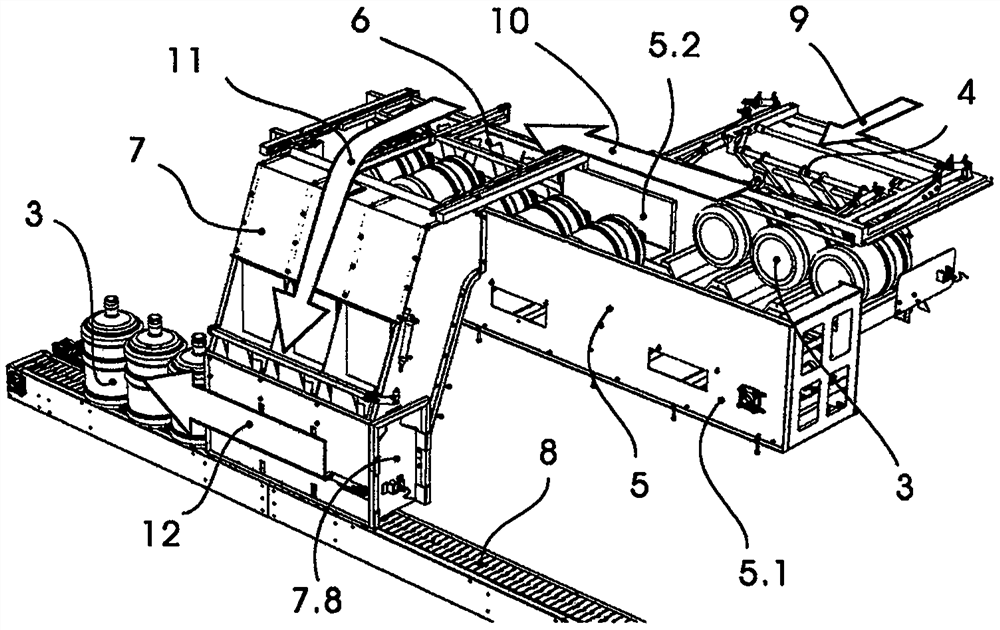

[0021] refer to figure 1 , figure 2 , image 3 : A kind of translation slide out bucket device of particle bucket washing machine comprises: rake bucket device (4), translation conveyor (5), push bucket device (6), glideway (7) constitute; The lowered packaging bucket (3) falls on the buffer tray (4.4) of the bucket rake (4), and is sent to the translation conveyor (5) by the bucket claw (4.21), and the translation conveyor (5) will pack the The barrel (3) is transferred to the upper opening of the glideway (7), and the barrel pusher (6) pushes the packaging barrel (3) into the glideway (7), and the packaging barrel (3) falls on the conveyor belt (8) to be transported Go, that is, move away from the particle barrel washing machine (1) in the direction indicated by the arrows (9), (10), (11.), and (12) along the movement direction of the packaging barrel.

[0022] Described bucket rake (4): as Figure 4 , 5 , 6, it includes parallel slideway (4.1), sliding frame (4.2), bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com