Production equipment and production method of energy-saving environment-friendly building board

A technology for building boards and production equipment, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve problems such as detachment from vacuum cranes, and achieve the effect of improving firmness and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

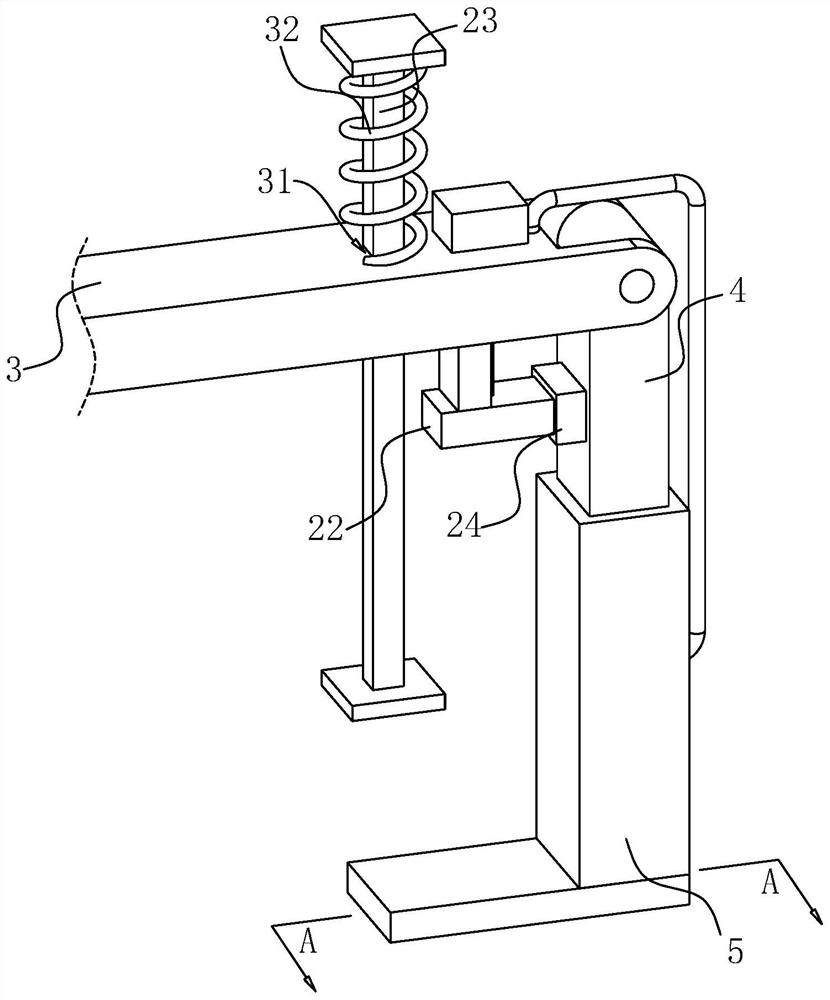

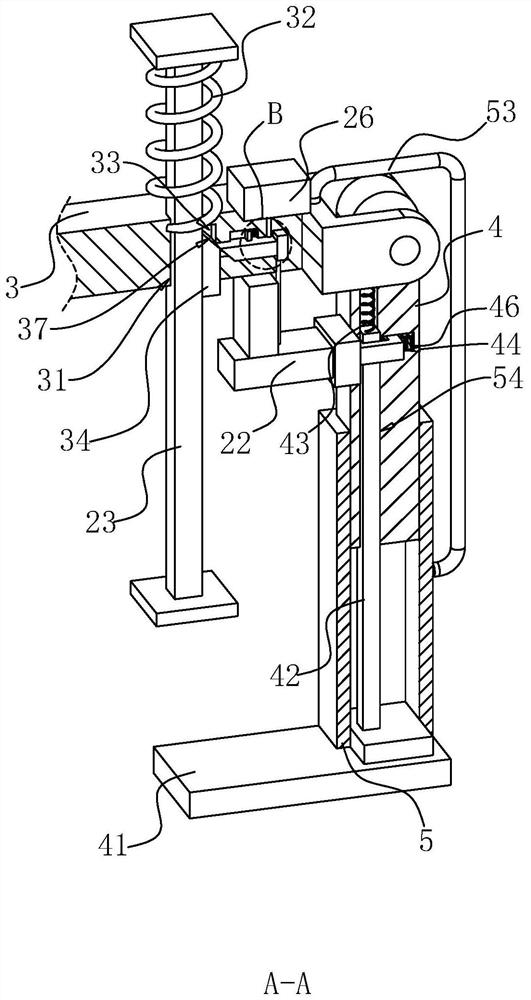

[0039] The following is attached Figure 1-6 The application is described in further detail.

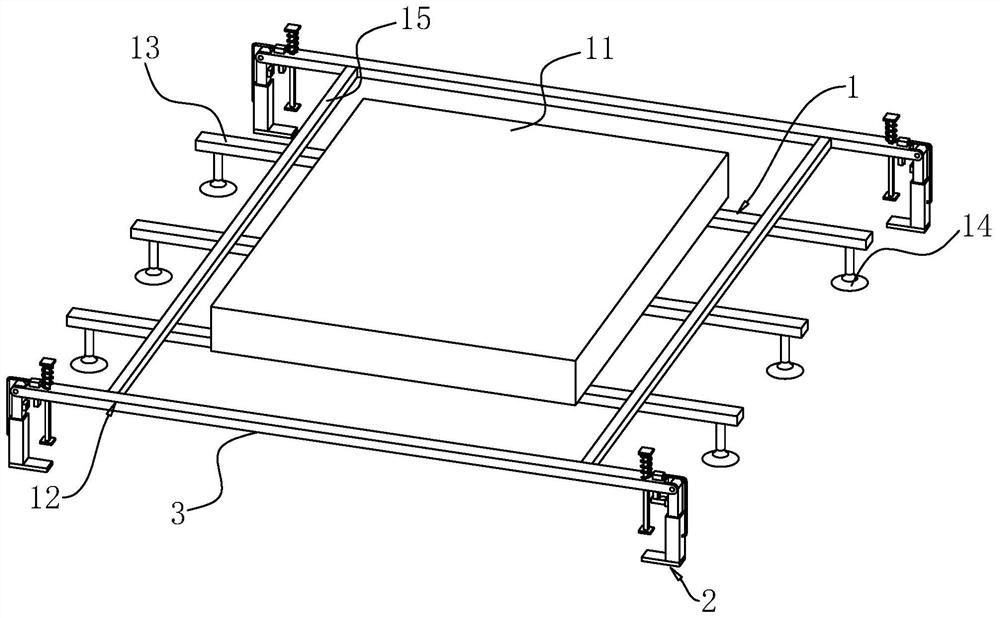

[0040] The embodiment of the present application discloses production equipment and production methods of energy-saving and environment-friendly building boards. refer to figure 1 , the production equipment of energy-saving and environment-friendly building panels includes a crane, and the crane includes a hanging plate 11 and an installation frame 1 fixed on the bottom of the hanging plate 11 . The installation frame 1 includes a square frame 12 and connecting rods 13 uniformly distributed on the bottom surface of the square frame 12 along the length direction of the square frame 12 . Two vacuum suction cups 14 are symmetrically fixed on the bottom of the connecting rod 13 . The square frame 12 includes two longitudinal bars 15 arranged along the length direction of the square frame 12 and a transverse bar 3 arranged along the width direction of the square frame 12 .

[0041] re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com