Laser cladding-double-wire CMT electric arc wire powder composite additive manufacturing system for heterogeneous component

A manufacturing system, laser cladding technology, applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of lower production efficiency, increased additive cost, high cost, etc., to improve additive accuracy and additive efficiency, Meet the needs of additive materials, with strong functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

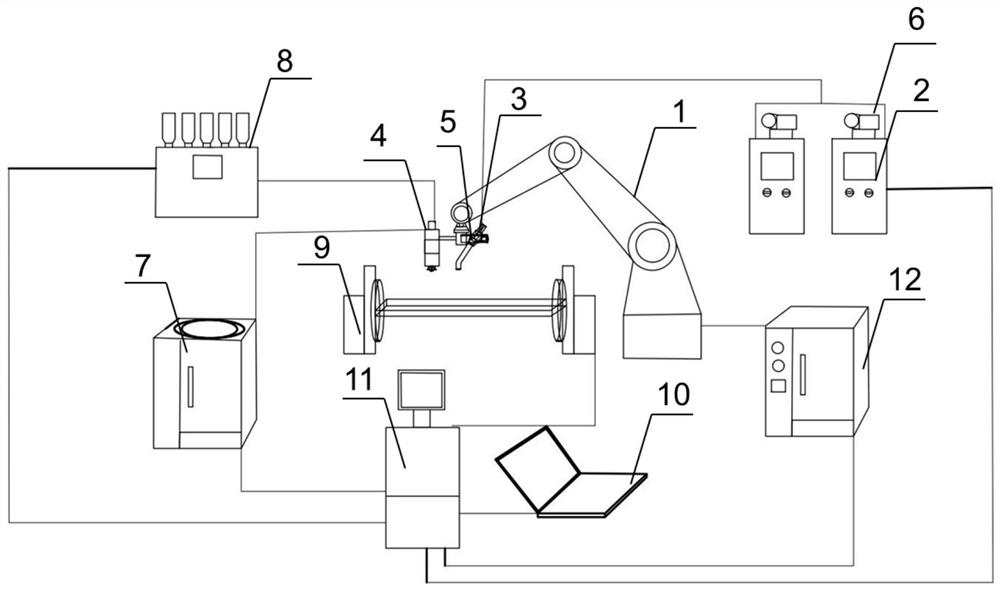

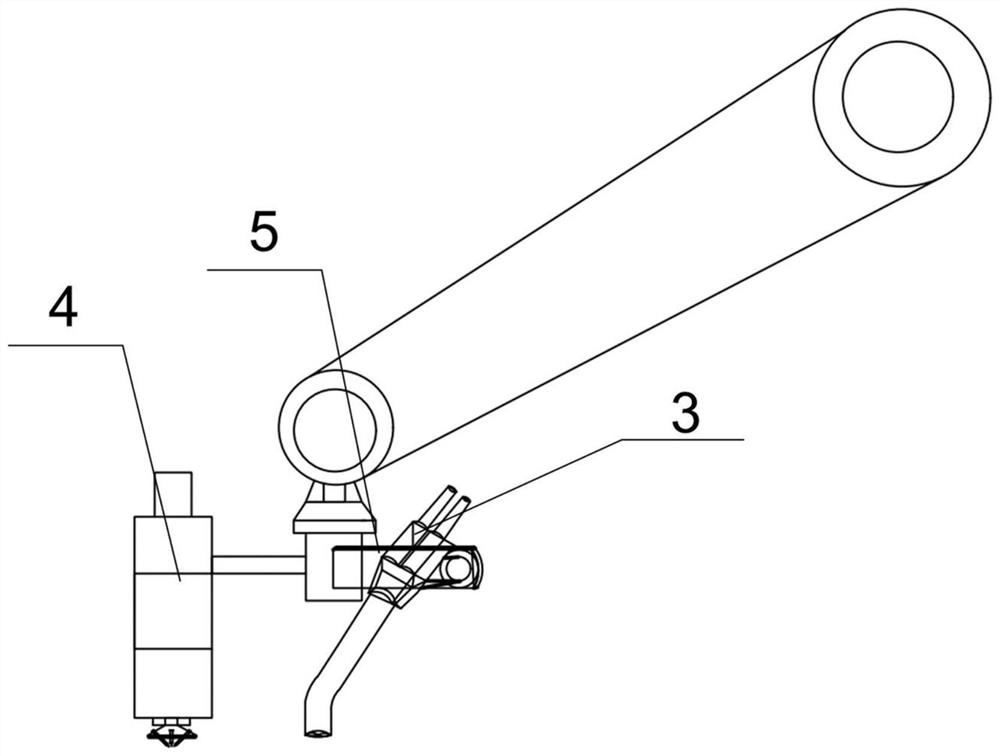

[0019] The invention provides a laser cladding-double-wire CMT arc wire powder composite material additive heterogeneous component manufacturing system, including a six-axis robot, two CMT welding power supplies, a CMT double-wire arc welding torch, a laser, a laser cladding welding torch, CMT arc welding torch and laser welding torch connection and control device, additive control system, CMT double wire feeding system, five-storage laser powder feeding system, two-axis additive collaborative positioner, layered modeling and intelligent planning software system; Among them, the CMT arc welding torch is connected with the laser welding torch and the control device is used to equip the CMT double-wire welding torch and the laser cladding welding torch on the same machine arm, and keep the bottom of the two welding torches on the same plane, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com