Construction technology of acrylic adhesive for leak plugging of power equipment under low temperature conditions

A technology of acrylic adhesive and acrylic glue, which is applied in the direction of electrical components, coatings, switchgear, etc., can solve problems such as uneven heating, leakage of harmful gas, and decline in equipment insulation, so as to increase applicability and reduce heat loss , increase the effect of plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] see Figure 10 , a construction process of an acrylic adhesive for plugging leakage of electric power equipment under low temperature conditions, and a construction process of the acrylic adhesive under low temperature conditions, the steps comprising:

[0042] S1, Acrylic adhesive storage: Before the construction of electric equipment leak plugging, wrap the acrylic adhesive with a silicone rubber heating tape and wrap it completely, then place it in an incubator for heating and storage, and adjust the temperature of the incubator as required;

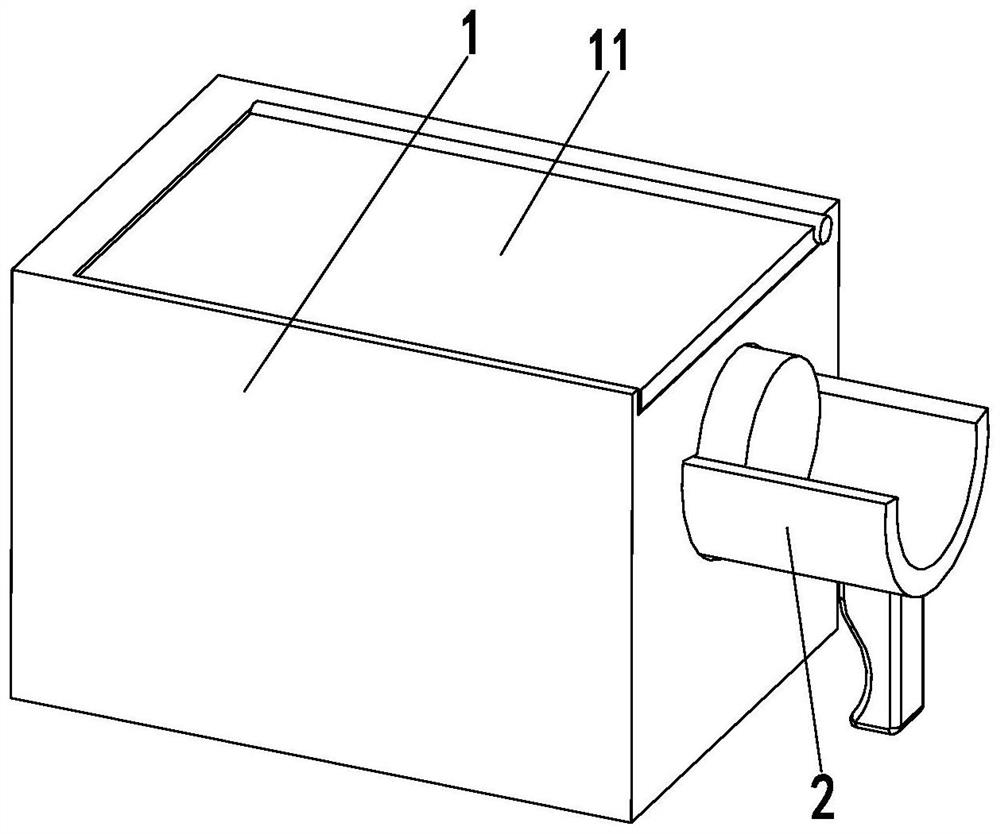

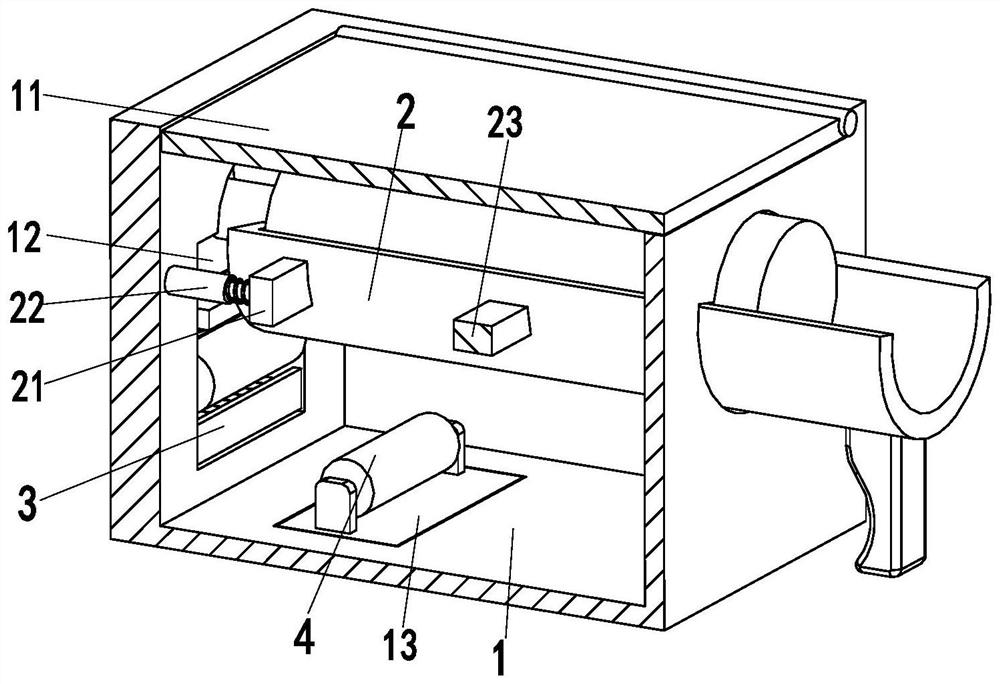

[0043] S2, acrylic adhesive locking: when the power equipment needs to be plugged, take out the acrylic adhesive from the insulation box and lock it on the glue gun set in the insulation leakage plug, and put it in the insulation leakage plug Place heating stickers so that the thermal insulation leak plug is at a suitable temperature;

[0044]S3, plugging construction: Align the acrylic adhesive outlet locked in the thermal in...

Embodiment 2

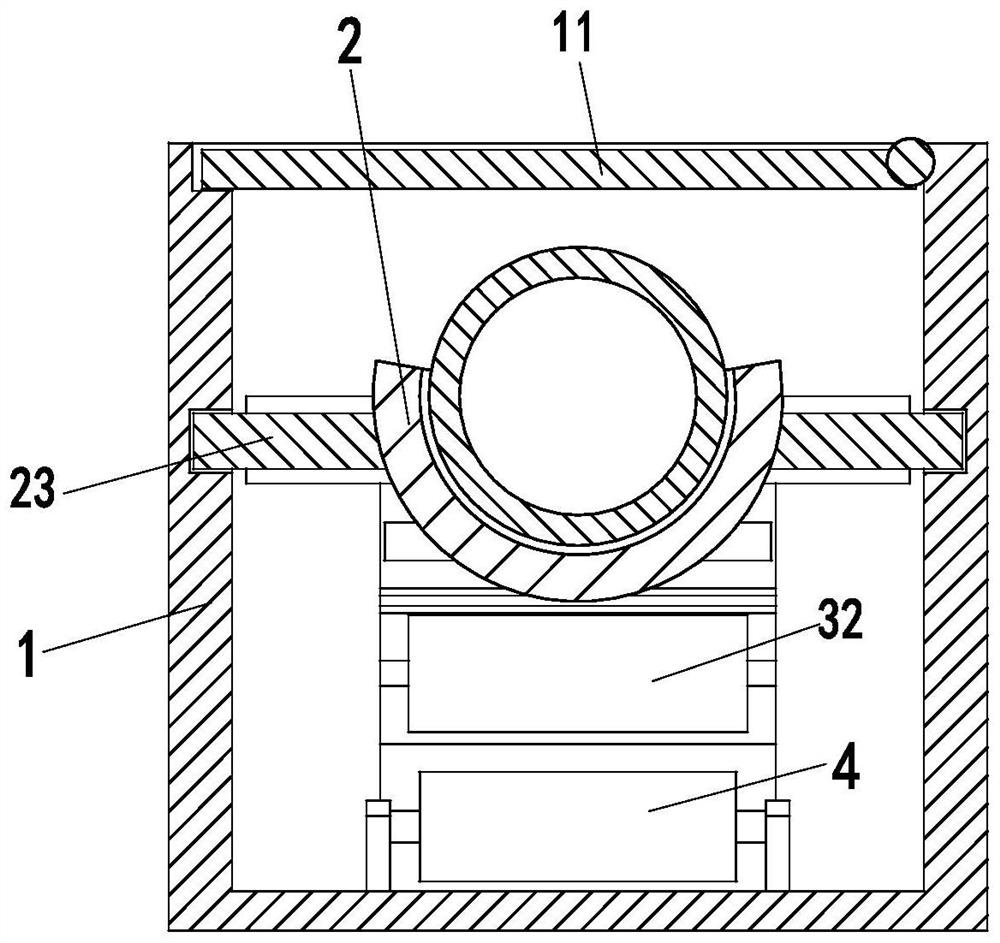

[0061] In this embodiment, an arc-shaped plate 5 is added on the basis of the heat preservation leak stopper in Embodiment 1. Please refer to Figure 7-Figure 8 , through the arc-shaped plate 5, the locking frame 1 can be used to plug the flange position of the pipeline in the power equipment. The arc-shaped plate 5 is sleeved on the left side of the locking frame 1, and the arc-shaped plate 5 is connected to the locking frame. The bodies 1 are locked to each other by bolts. It should be noted that the left ends of the rolling cylinder 32 and the flat plate 33 are located on the left side of the arc plate 5, so the installation of the arc plate 5 does not affect the laying of the rubber heating belt.

[0062] see Figure 7-Figure 8 The upper and lower ends of the arc-shaped plate 5 are provided with two limit clip slots 51, the two limit clip slots 51 are arranged symmetrically in the front and rear, and a limit column 53 is installed in each limit clip slot 51 through a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com