Staged exogenous auxiliary fermentation method of Pu'er tea

A technology of auxiliary fermentation and Pu'er tea, which is applied in the tea treatment before extraction, etc. It can solve the problems of Pu'er tea agglomeration, difficult to control and standardize the production method, and the dullness of the strips, so as to shorten the fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

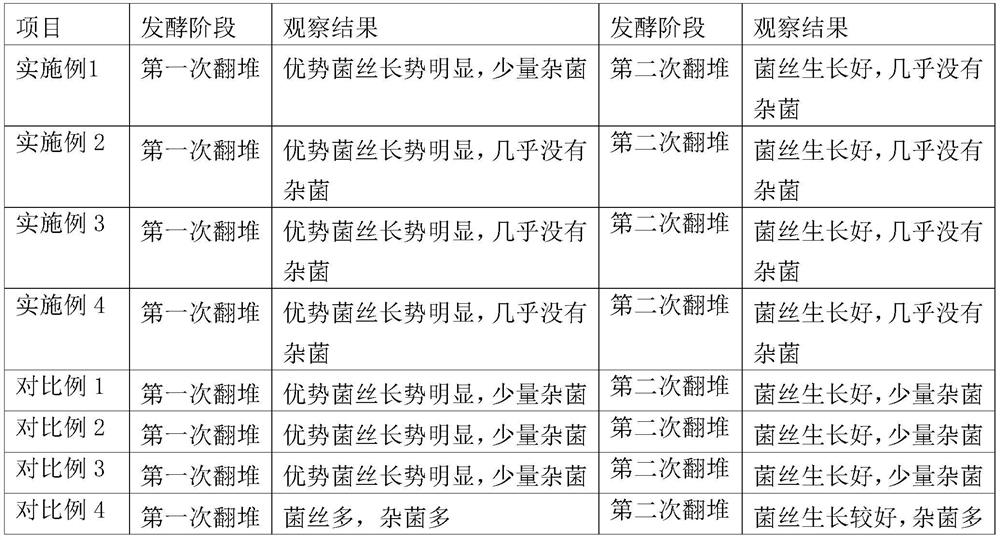

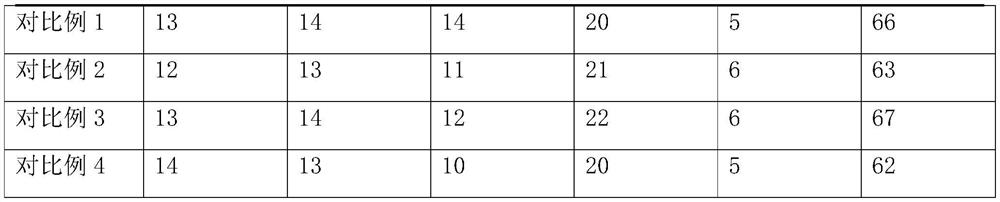

Examples

Embodiment 1

[0020] S1: Use Yunnan big leaf sun-dried green tea as raw material and place it in a fermenter for pile fermentation. The water content of the tea pile is 30% by spraying, and the compound starter A with 1% of the tea pile mass is dissolved in the tide water. The composite starter A is compounded with xylose, Aspergillus niger, and Penicillium in a mass ratio of 3:1:1, and the first turning is carried out after 4 days, and the temperature is kept at 30°C before turning;

[0021] S2: After turning the heap for the first time, add the compound yeast preparation to the tea heap, spray the compound yeast preparation by dissolving it in water, keep the water content of the tea heap at 30% after spraying, and turn the heap for the second time after 4 days, Keep the temperature at 25°C before turning the pile for the second time. The compound yeast preparation is compounded by Candida rugosa and Aspergillus niger in a mass ratio of 2:1. The spraying amount of the compound yeast prepar...

Embodiment 2

[0025] S1: Yunnan big leaf sun-dried green tea is used as raw material and placed in a fermenter for heap fermentation. The water content of the tea heap is 35% by spraying, and a compound starter A with a mass of 1.5% of the tea heap is dissolved in the tide water. The compound starter A is compounded with fructose, Aspergillus niger, and Penicillium in a mass ratio of 3:1:1, and the first turning is carried out after 5 days, and the temperature is kept at 33°C before turning;

[0026] S2: After turning over the pile for the first time, add the compound yeast preparation to the tea pile, spray the compound yeast preparation by dissolving it in water, keep the moisture content of the tea pile at 35% after spraying, and perform the second pile turning after 5 days, Keep the temperature at 28°C before turning the heap for the second time. The compound yeast preparation is composed of Candida rugosa and Aspergillus niger in a mass ratio of 2:1. The spraying amount of the compound ...

Embodiment 3

[0030] S1: Use Yunnan big leaf sun-dried green tea as raw material and place it in a fermenter for pile fermentation. The water content of the tea pile is 40% by spraying, and a compound starter A of 2% of the tea pile mass is dissolved in the tide water. The compound starter A is compounded with mannose, Aspergillus niger, and Penicillium in a mass ratio of 3:1:1, and the first turning is carried out after 6 days, and the temperature is kept at 35°C before turning;

[0031] S2: After turning over the pile for the first time, add the compound yeast preparation to the tea pile, spray the compound yeast preparation by dissolving it in water, keep the water content of the tea pile at 40% after spraying, and perform the second pile turning after 6 days, Keep the temperature at 30°C before turning the heap for the second time. The compound yeast preparation is composed of Candida rugosa and Aspergillus niger in a mass ratio of 2:1. The spraying amount of the compound yeast preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com