Low-temperature roasting furnace for producing amorphous aluminum oxide from crystalline aluminum chloride

A technology of amorphous alumina and crystalline aluminum chloride, which is applied in the field of low-temperature roasting furnaces to achieve the effects of fast heat and mass transfer, uniform temperature distribution, and adjustable residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

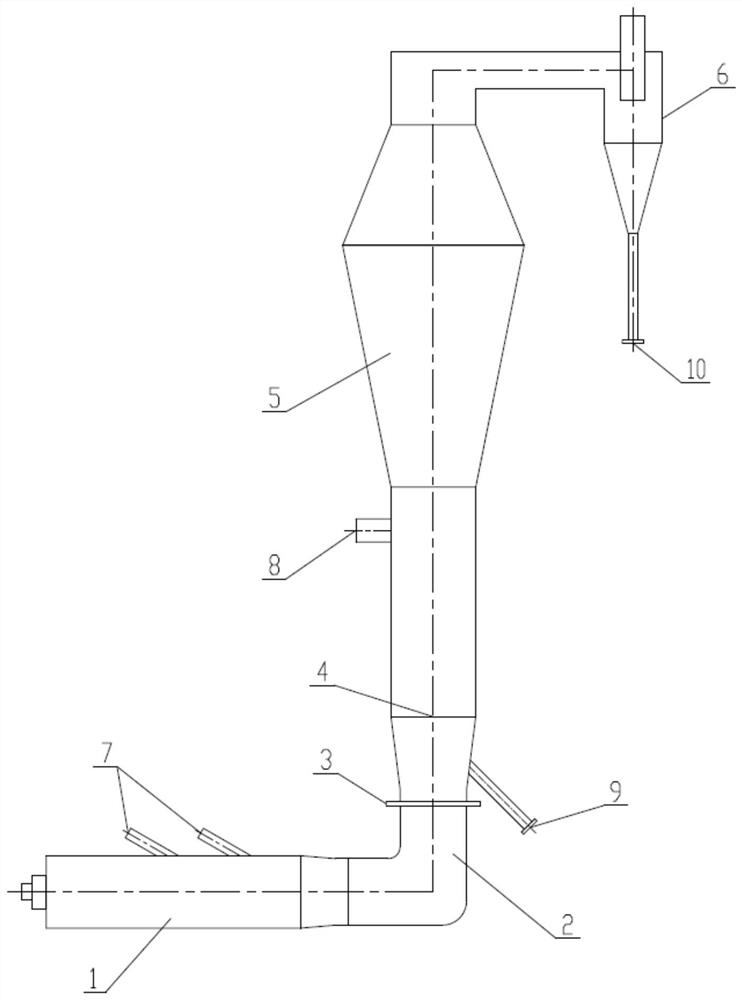

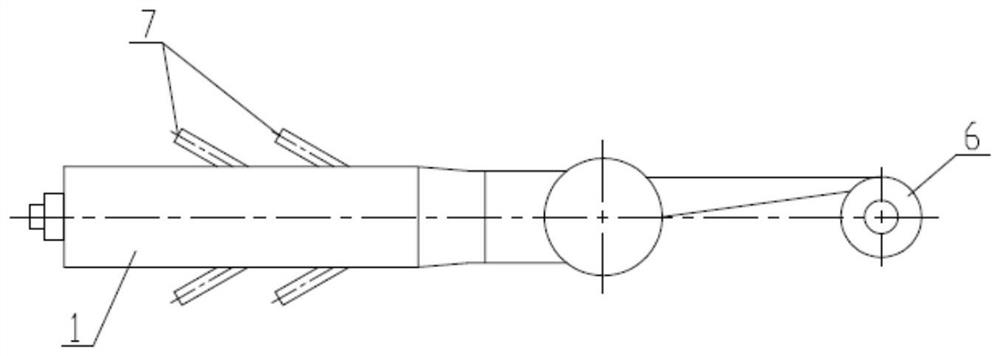

[0021] A low-temperature roasting furnace for producing amorphous alumina by crystalline aluminum chloride of the present invention comprises: a hot blast furnace 1, an air chamber 2, an air distribution plate 3, a furnace reaction zone 4, a furnace flare section 5, a cyclone separator 6, a cooling Tuyere 7, feed inlet 8, furnace discharge outlet 9 and cyclone separator feeding leg 10.

[0022] The high-temperature flue gas generated by the hot blast stove 1 is mixed with the multi-stage and evenly distributed cooling air from the cooling tuyere 7 and then enters the air chamber 2, and the flue gas in the air chamber 2 enters the furnace reaction zone 4 through the air distribution plate 3, so that the furnace reaction zone The crystalline aluminum chloride and alumina materials in 4 reach a fluidized state;

[0023] The flue gas heat in the furnace reaction zone 4 is transferred to the crystalline aluminum chloride material, and the crystalline aluminum chloride undergoes a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com