A kind of method for preparing alumina-dispersed copper by external oxidation

A technology of external alumina and dispersed copper, which is applied in the field of composite materials, can solve the problems of insufficient oxidation of pre-alloyed aluminum, degradation of material performance, and difficulty in cleaning, so as to reduce oxidation of copper powder, improve performance, and reduce oxidation of copper. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1. Perform sufficient external oxidation treatment on the aluminum-copper alloy powder to obtain external alumina-copper alloy powder; the aluminum-copper alloy powder is a powder formed by aluminum coating on the surface of copper particles, and the process of the sufficient external oxidation treatment is: Under atmospheric atmosphere, heat to 600℃ and then keep for 10h;

[0034] Step 2: Mix the outer alumina-copper alloy powder obtained in step 1 with copper powder to obtain a specific oxide alloy powder; the mass percentage of aluminum in the specific oxide alloy powder is 1%; the copper powder is oxygen-free copper pink;

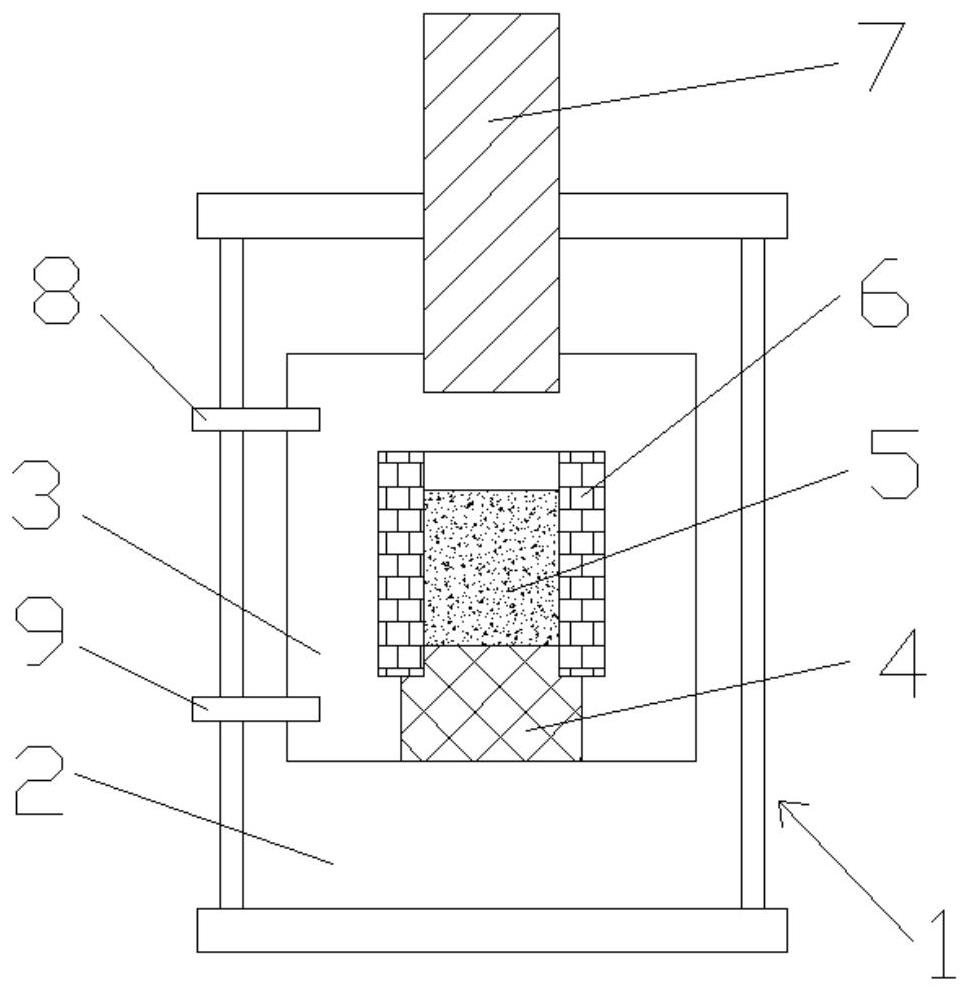

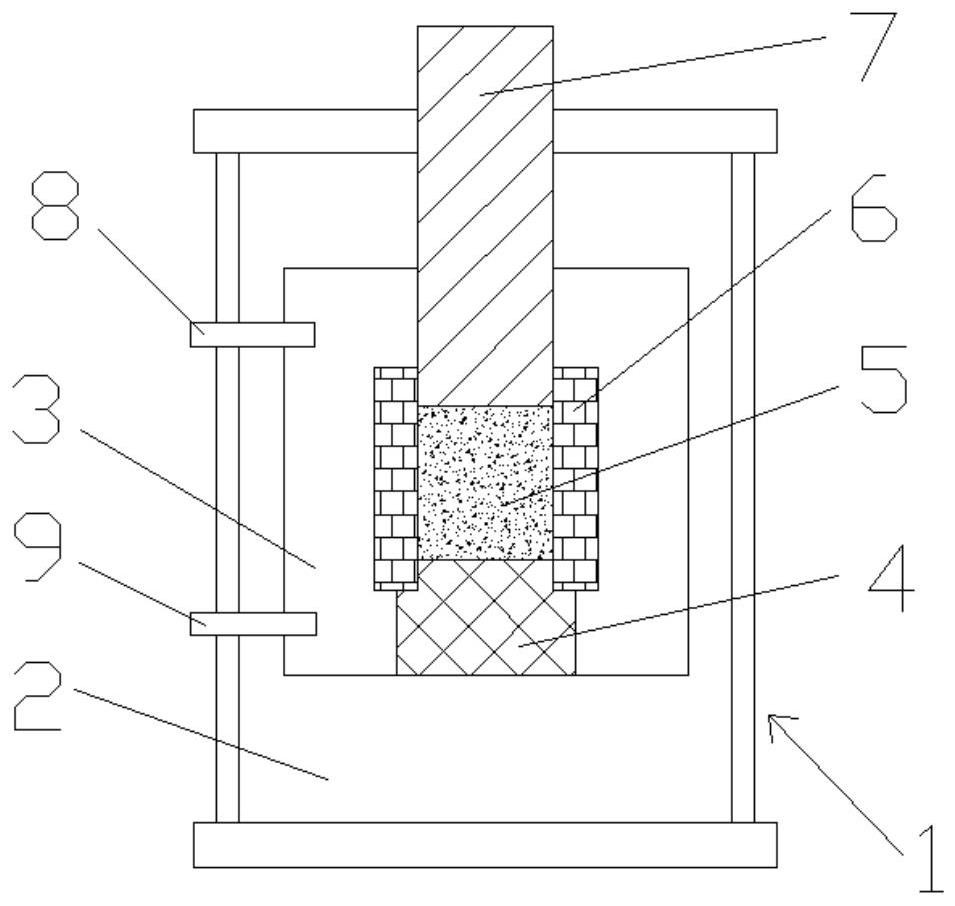

[0035] Step 3: Deoxidize and sinter the specific oxidized alloy powder obtained in the second step to obtain a dispersed aluminum-copper blank; the process of deoxidizing and hot-pressing sintering is as follows: firstly open the upper indenter 7 and put the specific oxidized alloy powd...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] Step 1. Perform sufficient external oxidation treatment on the aluminum-copper alloy powder to obtain external alumina-copper alloy powder; the aluminum-copper alloy powder is a powder formed by aluminum coating on the surface of copper particles, and the process of the sufficient external oxidation treatment is: In an oxygen atmosphere, heated to 300 ℃ and then kept for 30h;

[0041] Step 2: Mix the outer alumina-copper alloy powder obtained in step 1 with copper powder to obtain a specific oxide alloy powder; the mass percentage of aluminum in the specific oxide alloy powder is 0.5%; the copper powder is oxygen-free copper pink;

[0042] Step 3: Deoxidize and sinter the specific oxidized alloy powder obtained in the second step to obtain a dispersed aluminum-copper blank; the process of deoxidizing and hot-pressing sintering is as follows: firstly open the upper indenter 7 and put the specific oxidized alloy powd...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] Step 1. Perform sufficient external oxidation treatment on the aluminum-copper alloy powder to obtain external alumina-copper alloy powder; the aluminum-copper alloy powder is a powder formed by aluminum coating on the surface of copper particles, and the process of the sufficient external oxidation treatment is: Under the atmospheric atmosphere, heat to 700 ℃ and then keep for 5h;

[0048] Step 2: Mix the outer alumina-copper alloy powder obtained in step 1 with copper powder to obtain a specific oxide alloy powder; the mass percentage of aluminum in the specific oxide alloy powder is 0.1%; the copper powder is oxygen-free copper pink;

[0049] Step 3: Deoxidize and sinter the specific oxidized alloy powder obtained in the second step to obtain a dispersed aluminum-copper blank; the process of deoxidizing and hot-pressing sintering is as follows: firstly open the upper indenter 7 and put the specific oxidized allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com