Catalytic condition optimization method and system for synthesizing acrylic acid

An optimization method, acrylic technology, applied in neural learning methods, chemical process analysis/design, instruments, etc., can solve problems such as low selection efficiency and weak stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

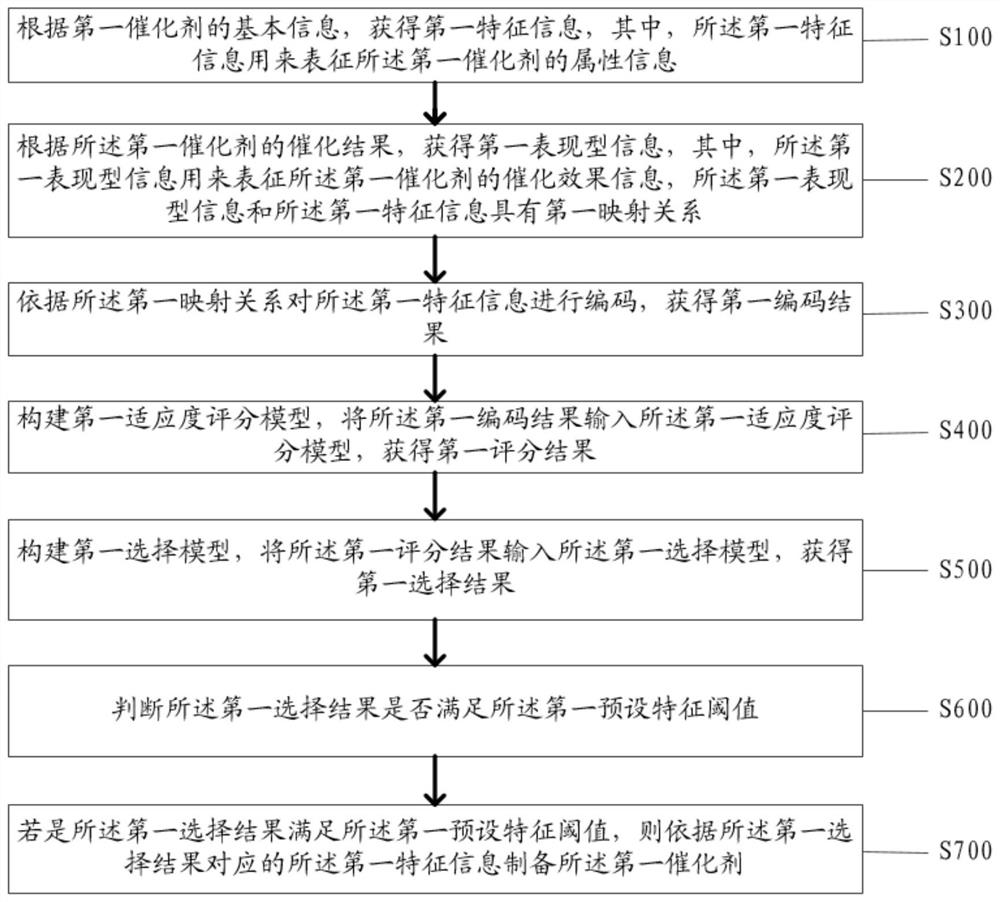

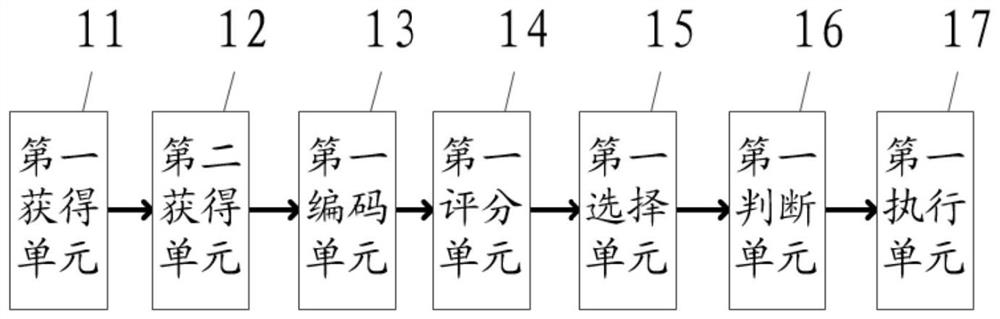

[0026] Such as figure 1 As shown, the embodiment of the present application provides a catalytic condition optimization method for synthesizing acrylic acid, wherein the method is applied to a catalytic condition optimization system, and the method includes:

[0027] S100: Obtain first characteristic information according to the basic information of the first catalyst, wherein the first characteristic information is used to characterize attribute information of the first catalyst;

[0028] Specifically, take the most common industrial acrylic acid production method: the two-step oxidation of propylene as an example. The first stage of the reaction is mainly to synthesize acrolein through propylene. The catalysts currently used are mainly Mo-Bi catalysts, and then Fe, Co, Ni, Mn, Mg and other multiple metal elements are used as additives for catalysis. The second-stage reaction is mainly to synthesize acrylic acid through acrolein. The catalysts currently used are mainly Mo-V ca...

Embodiment approach 1

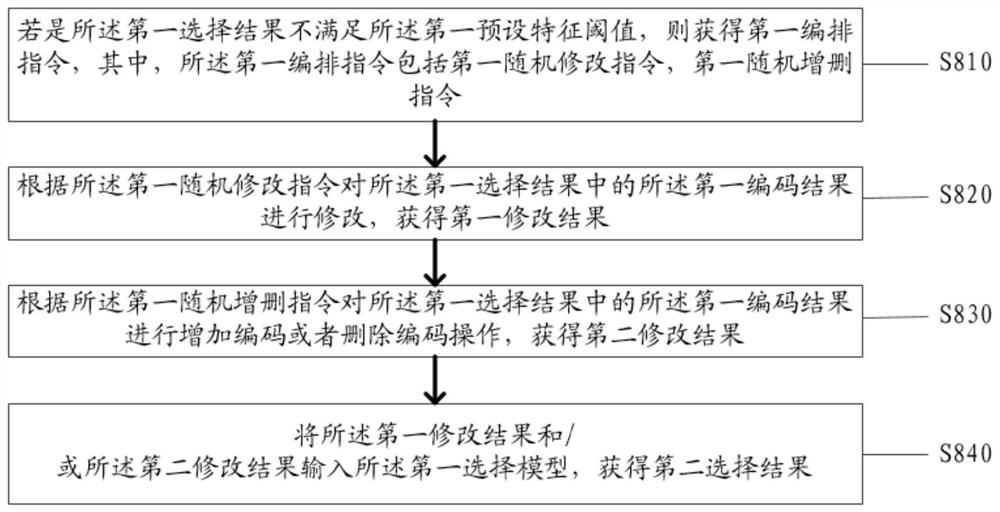

[0047] Embodiment 1: replace the original code with a new code for the first coding result corresponding to the first selection result;

Embodiment approach 2

[0048] Embodiment 2: Adjust the coding order of the first coding result corresponding to the first selection result; obtain the first modification result after modification. The first and second implementations can be implemented at the same time or only one of them can be implemented. When the first encoding result that has been screened out is the same, it will be screened out again.

[0049] The first programming instruction includes the first random addition and deletion instruction, and the first encoding result in the first selection result can be adjusted in the following two ways through the first random addition and deletion instruction:

[0050] Embodiment 1: The first encoding result in the first selection result can be added or deleted through the first random addition and deletion instruction;

[0051] Embodiment 2: The first coding result in the first selection result can be added and deleted through the first random addition and deletion instruction; the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com