Non-design working condition operation method of compressed air energy storage system

A technology of compressed air energy storage, non-design working conditions, applied in mechanical equipment, wind energy power generation, heat storage equipment, etc. Energy storage system performance degradation and other problems, to achieve the effect of improving energy conversion and waste heat utilization, improving operation stability and performance under variable conditions, and improving operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

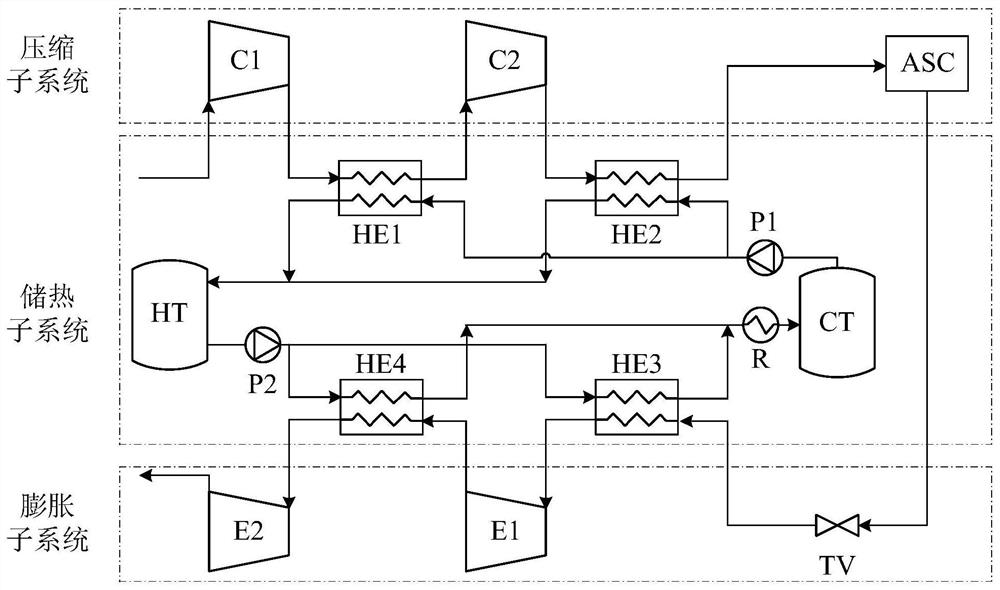

[0108] Such as figure 1 For the compressed air energy storage system shown, when the operating environment temperature is 5°C, its operation method is determined as follows:

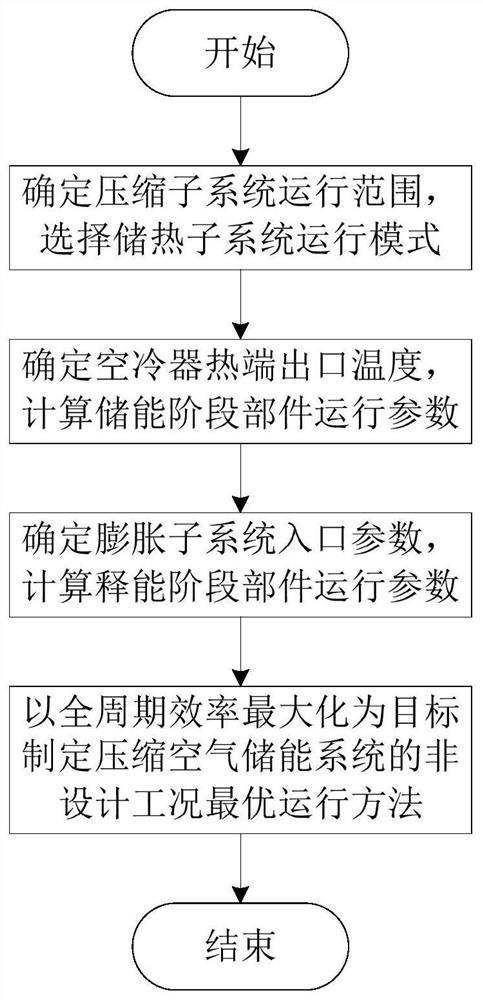

[0109] Step 1: Determine the operating range of the compression subsystem and select the operating mode of the heat storage subsystem.

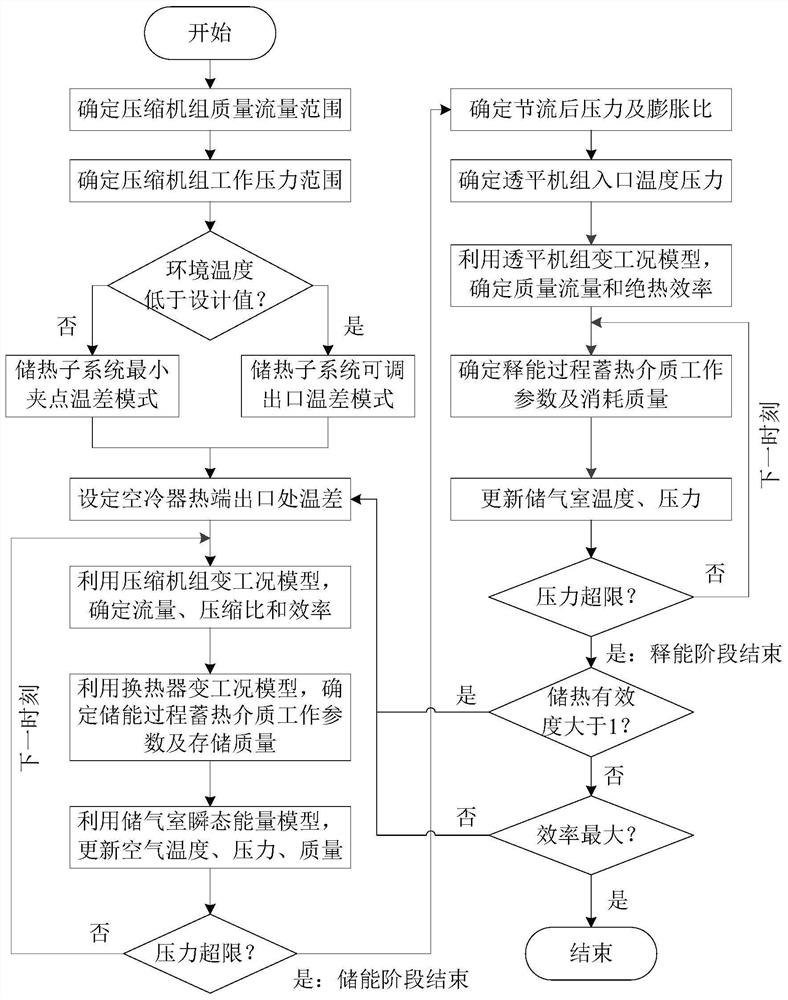

[0110] Determine compressor train mass flow and pressure range:

[0111] max(G min,i ,i=1L n)≤G≤min(G max,i ,i=1L n)

[0112] p v,min ≤p≤p v,max

[0113] Set the operation mode of the heat storage subsystem: in the energy storage stage, the air cooler operates in the mode of adjustable outlet temperature difference; in the energy release stage, the reheater operates in the mode of minimum pinch temperature difference.

[0114] Step 2: Set the outlet temperature difference of the hot end of the air cooler, and establish a parameter control model for the components in the energy storage stage.

[0115] Set the outlet temperature difference ΔT of the hot end of the...

Embodiment 2

[0125] Such as figure 1 For the compressed air energy storage system shown, when the operating environment temperature is 35°C, the optimal operation method for its full-cycle efficiency is as follows:

[0126] Determine compressor train mass flow and pressure range:

[0127] max(G min,i ,i=1L n)≤G≤min(G max,i ,i=1L n)

[0128] p v,min ≤p≤p c,max

[0129] Set the air cooler and reheater of the heat storage subsystem to operate in the minimum pinch temperature difference mode;

[0130] Set the outlet temperature difference ΔT of the hot end of the air cooler o = 10°C.

[0131] At this time, the full-cycle efficiency of the system can be obtained as 61.34%, and the output power is 159.9MW.

[0132] In summary, the non-design operation method of the compressed air energy storage system provided by the embodiment of the present application comprehensively considers the impact of environmental state changes on the main working components of the compressed air energy storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com