Continuous amylase conversion device

A conversion device and amylase technology, applied in the field of papermaking, can solve problems such as unusable equipment, high energy consumption, and impact on papermaking progress, so as to reduce energy consumption, improve work efficiency, and ensure processing progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

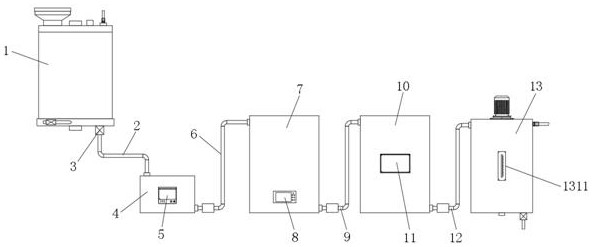

[0032] Such as Figure 1-6 As shown, the embodiment of the present invention provides a continuous amylase conversion device, including a premixing mechanism 1, a low-temperature heater 4, a heat preservation cabinet 7, a high-temperature cooking cabinet 10, and a concentration adjustment mechanism 13. The bottom end of the premixing mechanism 1 is fixed A discharge pipe 2 is connected, and the end of the discharge pipe 2 close to the pre-mixing mechanism 1 is equipped with a discharge solenoid valve 3, and the end of the discharge pipe 2 far away from the pre-mixing mechanism 1 is fixedly connected with a low-temperature heater 4, and the front end of the low-temperature heater 4 The center of the outer surface is provided with a first control panel 5;

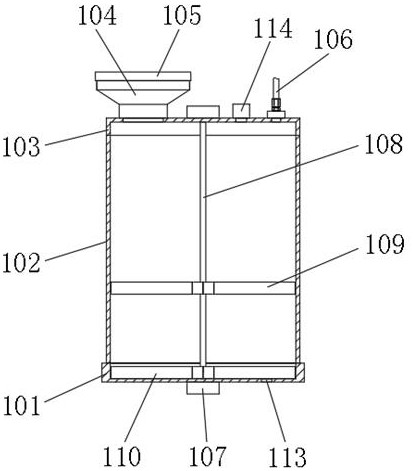

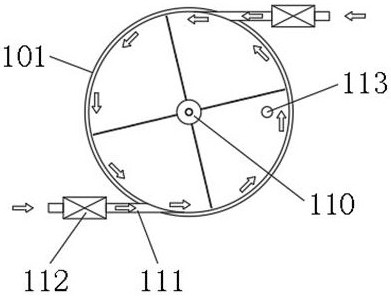

[0033] Such as Figure 2-4 As shown, the pre-mixing mechanism 1 includes a fixed base 101, the top of the fixed base 101 is fixedly connected with a mixing tank 102, the top of the mixing tank 102 is equipped with a detachab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com