Auxiliary beam of bogie

An auxiliary beam and bogie technology, applied in the field of rail vehicles, can solve the problems of complex structure, heavy metal beam structure, inconvenient maintenance and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

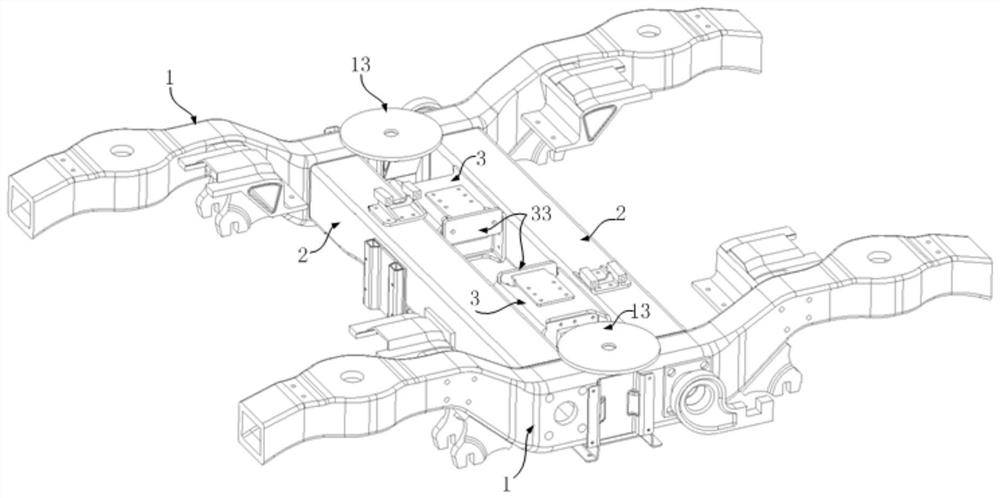

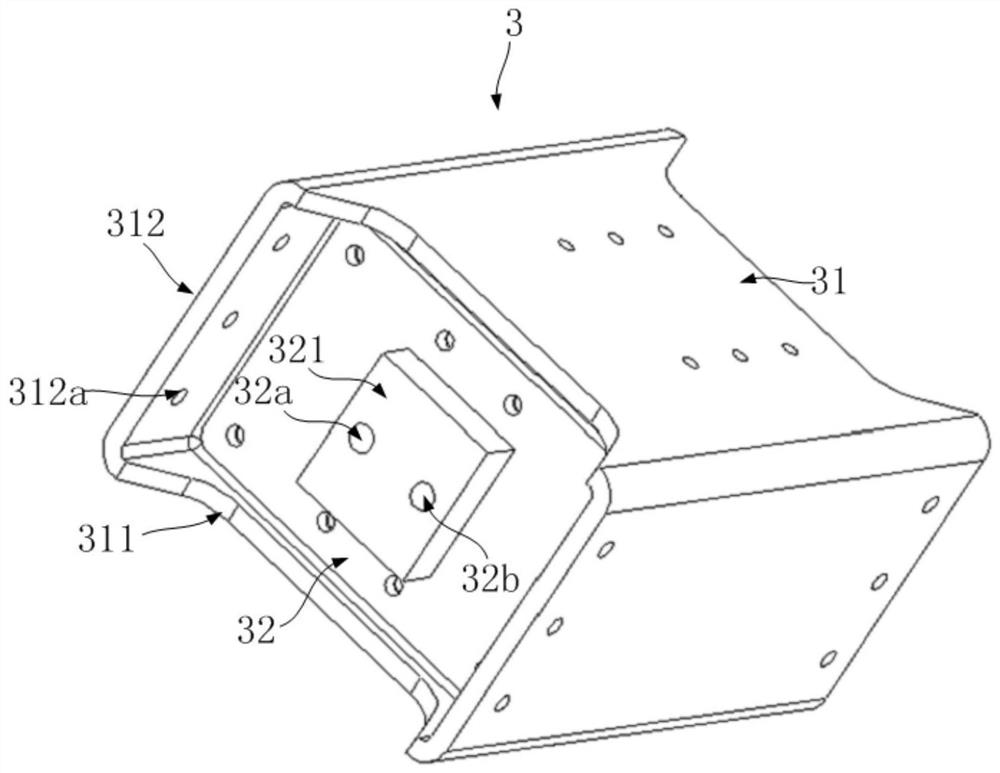

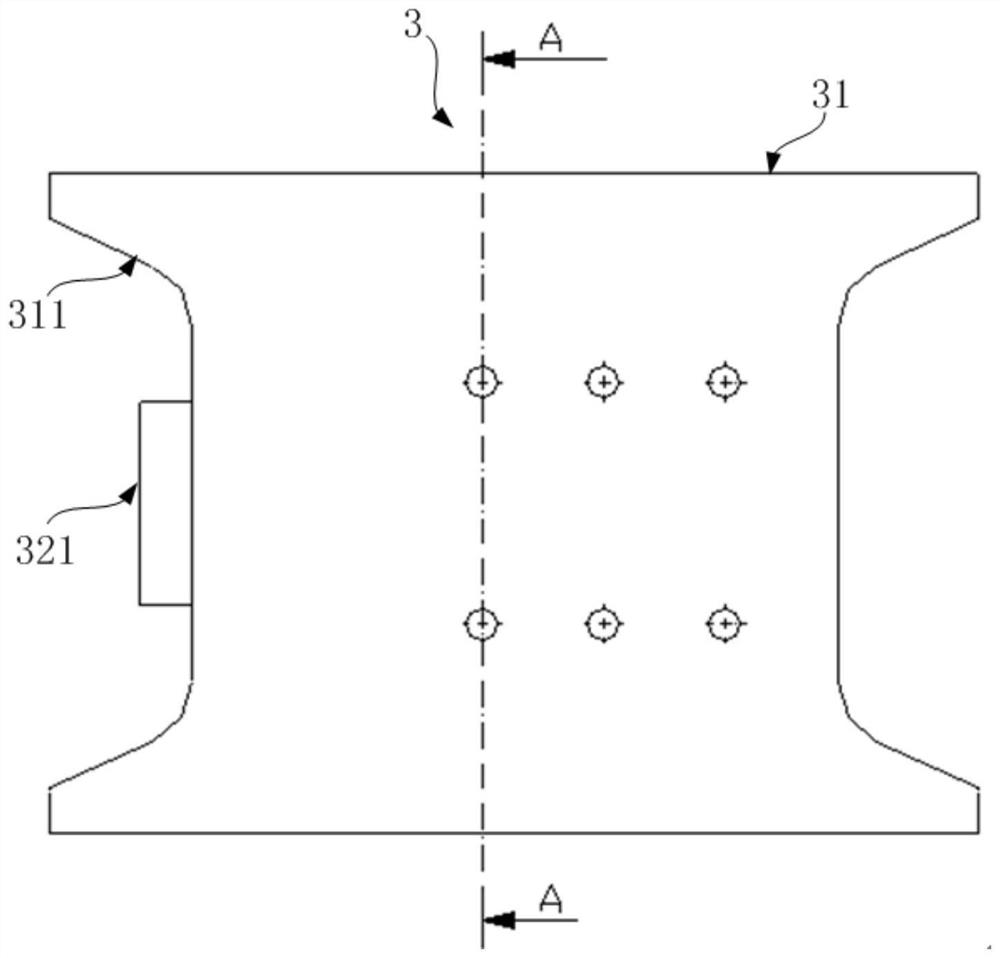

[0048] Please refer to Figure 2-9 , figure 2 It is the structural representation of auxiliary beam 3 in embodiment 1; image 3 for figure 2 main view of Figure 4 for image 3 right view of Figure 5 for Figure 4 left view of Image 6 for image 3 top view of Figure 7 for image 3 A-A sectional view; Figure 8 for Figure 5 B-B direction view; Figure 9 It is the C-C direction view of Figure 5.

[0049] like figure 2 , 7 As shown, the auxiliary beam 3 in this embodiment includes a casing 31 forming a closed cavity, and a partition 313 is arranged in the cavity of the casing 31, and the partition 313 divides the cavity into a first cavity 3a and a second cavity 3b. like figure 2 As shown, the housing 31 in Embodiment 1 is roughly square in shape, image 3 shows the top of the housing 31, image 3 The upper and lower sides of the middle housing 31 are respectively the front and rear sides of the housing 31, and the front and rear sides are the front an...

Embodiment 2

[0063] Please refer to Figure 10-16 , Figure 10 It is the front view of auxiliary beam 3 in embodiment 2; Figure 11 is the right view of Figure 10; Figure 12 for Figure 10 left view of Figure 13 for Figure 10 top view of Figure 14 for Figure 10 A-A sectional view of A-A; Figure 15 for Figure 12 B-B direction view; Figure 16 for Figure 12 C-C direction view.

[0064] The structure of the auxiliary beam 3 in the second embodiment is basically the same as that in the first embodiment, and only the differences will be described below, and the rest of the parts are the same and will not be repeated here. The difference is that in Embodiment 2, the first chamber 3a and the second chamber 3b of the housing 31 are not provided with inner linings. At this time, in order to facilitate the connection with external components, the special connection seat provided is no longer a sealed box, but Figure 14-16 The connection seat structure shown in.

[0065]The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com