Carbon fiber composite honeycomb and preparation method and application thereof

A composite material and carbon fiber technology, applied in the field of core material manufacturing, can solve problems such as thermal expansion mismatch of heterogeneous materials, structural damage of components, and limited weight loss effect of honeycomb mechanical properties, achieving high comprehensive performance and strong design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] A method for preparing a lightweight, high-strength, high-rigidity carbon fiber composite material honeycomb, comprising the following steps:

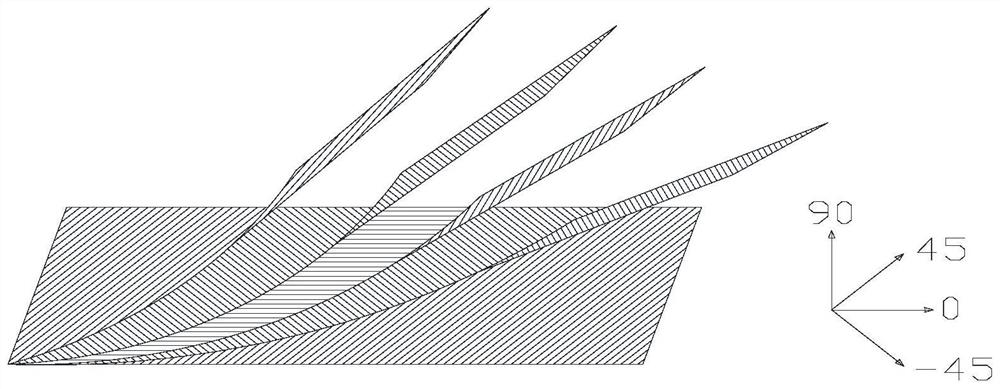

[0067] In step (1), disperse and expand the carbon fiber tow, and compound it with the resin film layer to prepare a unidirectional carbon fiber prepreg, and the surface density of the prepreg is controlled at 20-165g / m 2 Between, resin mass content is controlled between 30%-38%;

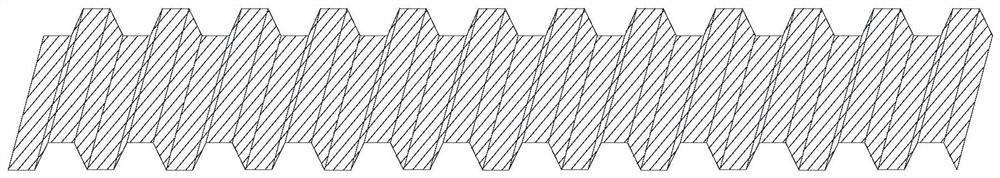

[0068] In step (2), the unidirectional carbon fiber prepreg obtained in step (1) is placed on the honeycomb laminate assembly compaction mold according to the optimally designed ply sequence, and each laying 1- 2 layers, vacuum and cold press the laid prepreg;

[0069] In step (3), cold press the prepreg obtained in step (2), and the compaction time is not less than 10 minutes, and the blank is taken out from the layup mold to obtain a hole wall laminate combination that roughly maintains a concave-convex shape Body blank;

[0070] In step (4), acc...

Embodiment 1

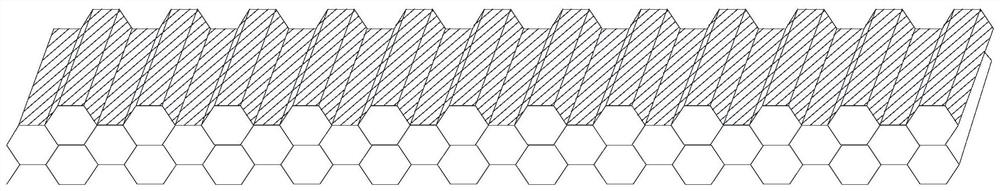

[0085] A light-weight, high-strength, high-rigidity carbon fiber composite material honeycomb. The cells of the carbon fiber composite material honeycomb are hexagonal cells surrounded by hole wall materials. figure 1 As shown, the laying direction of the honeycomb surface layer and the longitudinal angle of the honeycomb are 45°. The carbon fiber in the carbon fiber composite material is T700 grade carbon fiber, and the resin matrix is toughened epoxy resin cured at high temperature; the density of the honeycomb body is 72kg / m 3 , the structural parameters (including the cell side length, wall thickness, and layering sequence of the composite) are determined according to the honeycomb density and comprehensive mechanical properties (including plane tension, plane compression, plane shear, long beam bending and lateral pressure properties) According to the design, the specific structural parameters are: the side length of the cell is 5.8mm, the wall thickness is 0.15mm, and...

Embodiment 2

[0099] A light-weight, high-strength, high-rigidity carbon fiber composite material honeycomb. The cells of the carbon fiber composite material honeycomb are hexagonal cells surrounded by hole wall materials. figure 1 shown. The carbon fiber of the carbon fiber composite material is M40 grade carbon fiber, and the resin matrix is toughened epoxy resin cured at high temperature; the honeycomb density is 64kg / m 3 , structural parameters (including cell side length, wall thickness, composite layup sequence), based on honeycomb density and comprehensive mechanical properties (including plane tension, plane compression, plane shear, long beam bending and lateral pressure performance) requirements According to the design, the specific structural parameters are: the cell side length is 5.8mm, the wall thickness is 0.12mm, and the laying sequence of the composite is [60 / 0 / -60]. The laminated assembly is achieved by laying and laminating three layers of unidirectional carbon fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com