High-voltage circuit breaker

A high-voltage circuit breaker and controller technology, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of high cost, long time, and complicated operation for manufacturers, and achieve simple operation of input and withdrawal. Easy to operate, easy to disassemble and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

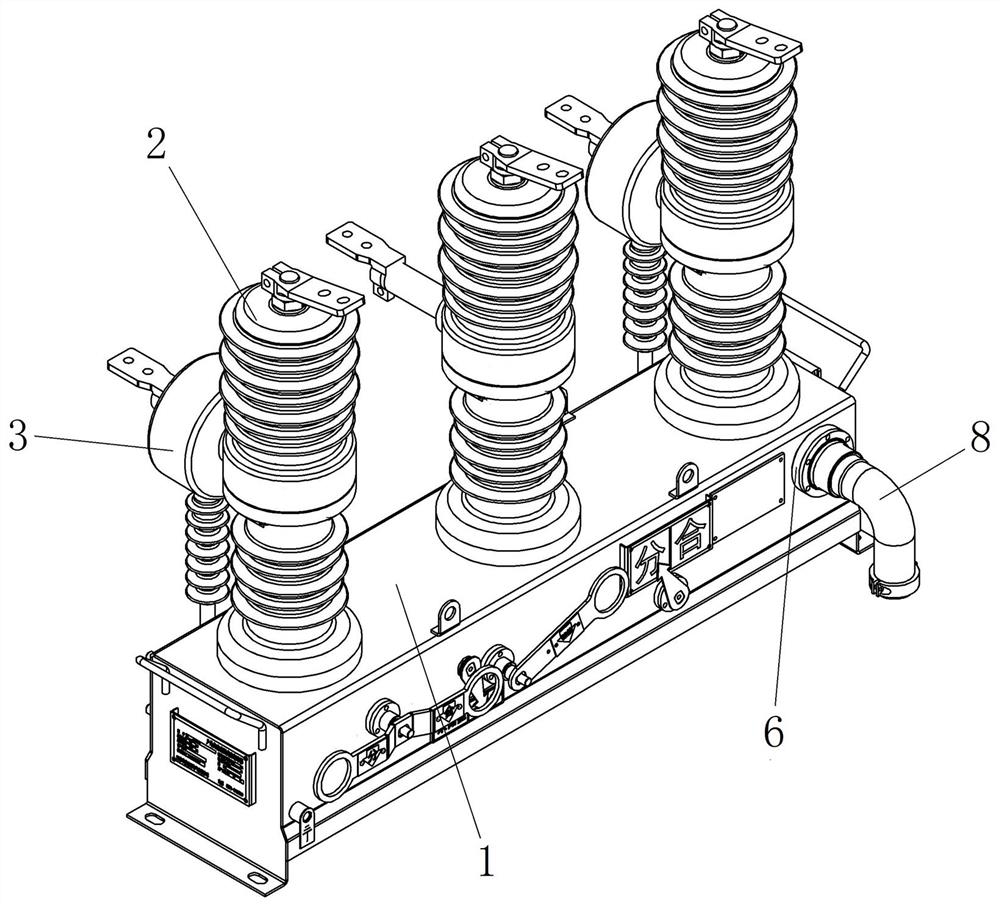

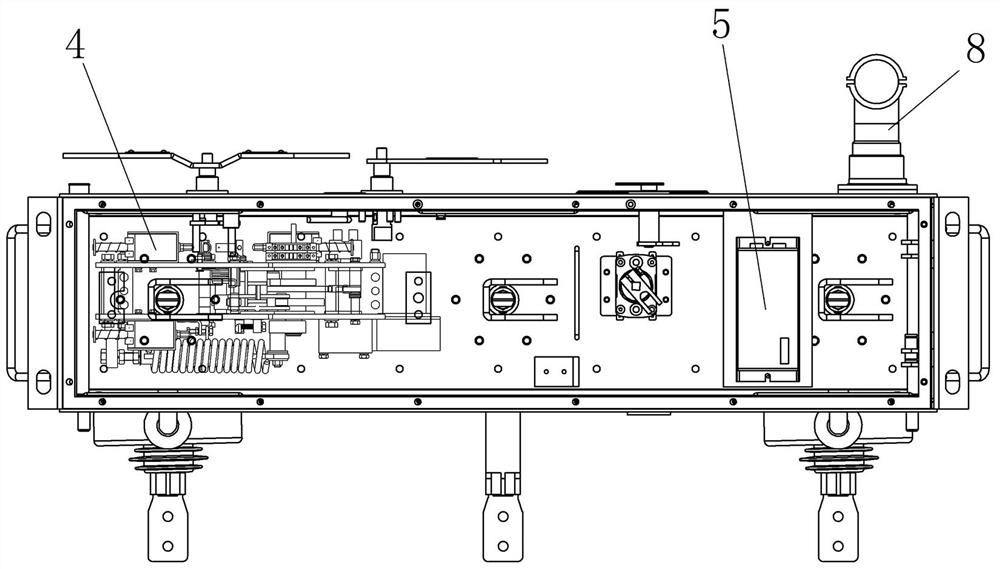

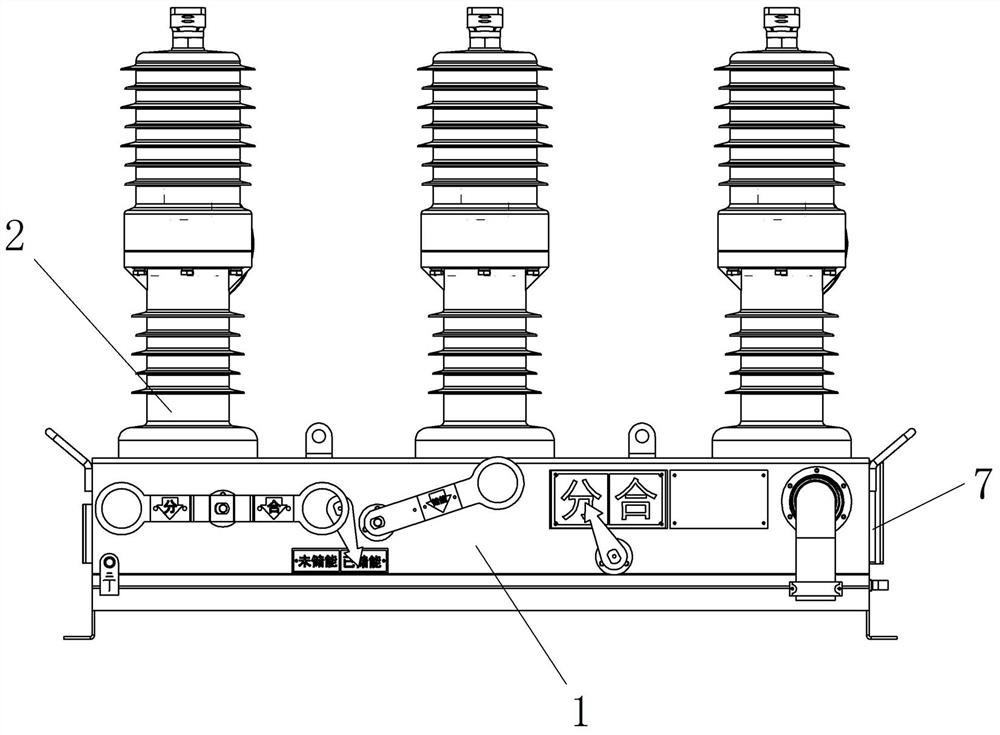

[0043] The structure of the high-voltage circuit breaker provided by this embodiment is as follows: figure 1 As shown, it includes the mechanism box 1, the solid-sealed pole 2, and the current transformer 3, and the solid-sealed pole 2 and the current transformer 3 are fixed on the mechanism box 1, such as figure 2 As shown, the mechanism box 1 is provided with a driving mechanism, specifically, the driving mechanism includes a mechanism release coil 4 arranged in the mechanism box 1, and the high-voltage circuit breaker also includes an inrush current controller 5 arranged in the mechanism box 1, and the inrush current The controller is connected with the mechanism release coil 4 for control.

[0044] In order to make the inrush controller 5 easy to switch on and off, the high-voltage circuit breaker also includes an adapter seat arranged on the mechanism box 1 , and the adapter seat is used for switching between the inrush controller 5 and the current transformer 3 . In th...

specific Embodiment 2

[0053] The specific embodiment 2 of the high-voltage circuit breaker provided by the present invention is mainly different from the embodiment 1 in that: in the embodiment 1, the high-voltage circuit breaker has two kinds of adapters at the same time, so that the user can choose according to the actual situation. In the embodiment, the high-voltage circuit breaker only has a socket-type adapter seat. Of course, in other embodiments, the high-voltage circuit breaker may only have a terminal-type adapter seat.

specific Embodiment 3

[0054] The specific embodiment 3 of the high-voltage circuit breaker provided by the present invention differs from the embodiment 1 mainly in that: in this embodiment, the aviation plug does not have a pin, but only has a strip-shaped connecting conductor on the end surface of the plug-in end. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com