Method for monitoring aging degree of transformer insulating oil

A transformer insulating oil, aging degree technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., to avoid equipment accidents, ensure operation safety, and reduce major losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The monitoring method for the aging degree of transformer insulating oil includes the following steps:

[0033] (1) Acquisition of working samples of transformer insulating oil

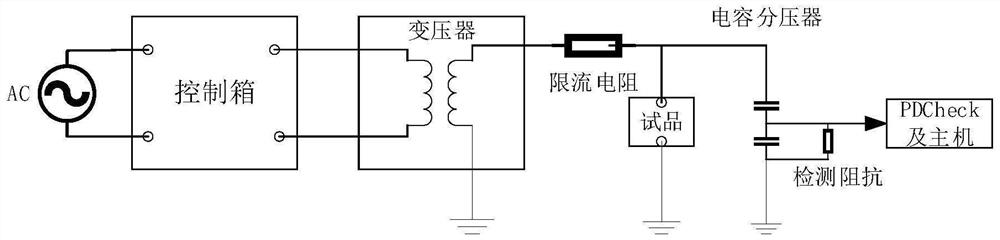

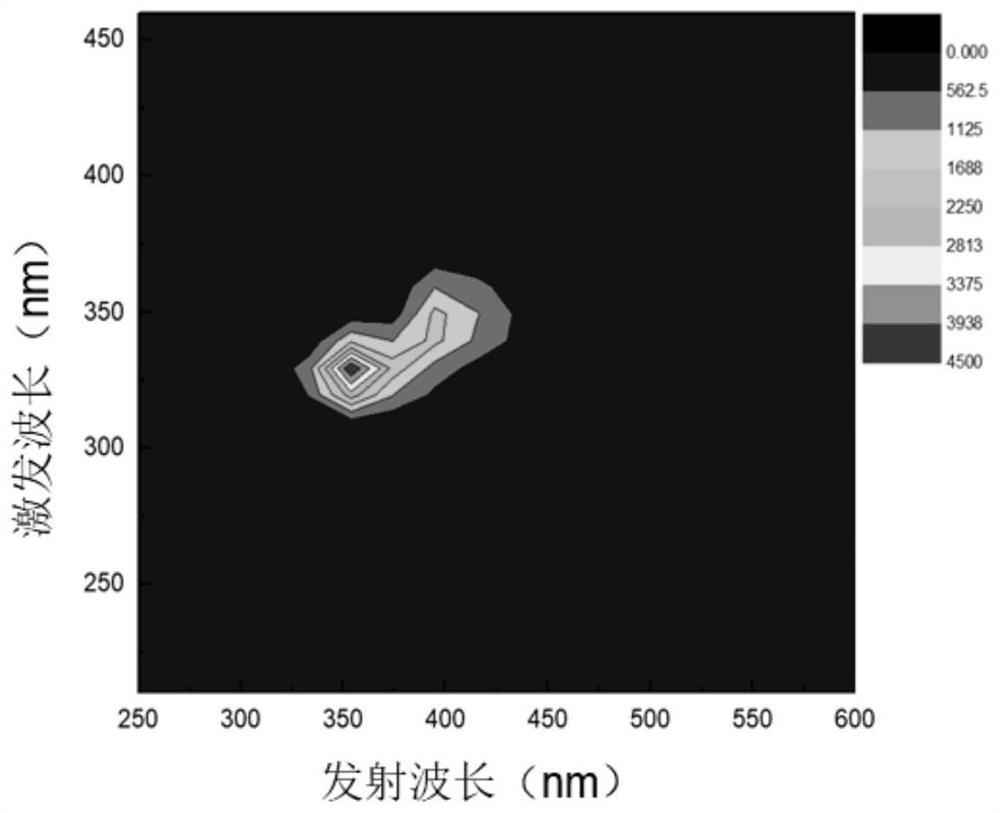

[0034] Using the same batch of transformer insulating oil samples as the substrate, continuous surface discharge experiments are carried out on the discharge device. The test discharge device is shown as figure 1 As shown, the experimental device is an existing device with a cavity volume of about 3L. The purpose of placing double layers of insulating paper is to avoid breakdown of insulating oil.

[0035] (1) The series resonance test device is used as a booster device, and the existing pulse current method is used as a partial discharge measurement method. Circuit principle such as figure 2 shown. The present invention can also use other methods in the prior art to perform partial discharge on the insulating oil, thereby simulating the natural lightning strikes that the insulating oil re...

Embodiment 2

[0065] For verifying the sensitivity of the inventive method, adopt step (3) in embodiment 1 to detect following actual oil sample to be tested, measurement result is as follows Figure 5 and shown in Table 1.

[0066] Table 1 Test results

[0067] batch number Sample name Fluorescence intensity (a.u.) 1 Fresh oil without shock 5526 2 Oil samples artificially simulated for a period of time by electric shock 3527 3 Oil samples that have been in operation for ten years 268.4

[0068] In the table, 1 represents the new oil that has not undergone electric shock, 2 represents the oil sample that artificially simulates the natural electric shock for a period of time, and 3 represents the oil sample that has actually been operated for ten years.

[0069] From the above examples and results, it can be known that the present invention is easy to operate, high in sensitivity, small in sample size, and can obtain data on the aging degree of insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com