Wheel-rail force testing method for bogie of three-piece truck

A test method and bogie technology, applied in the field of truck testing, can solve the problems of high production cost, long production cycle, inability to obtain wheel-rail force information, etc., to avoid errors and discrepancies with reality, reduce test costs, and achieve true test results. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The technical scheme that the present invention solves the problems of the technologies described above is as follows:

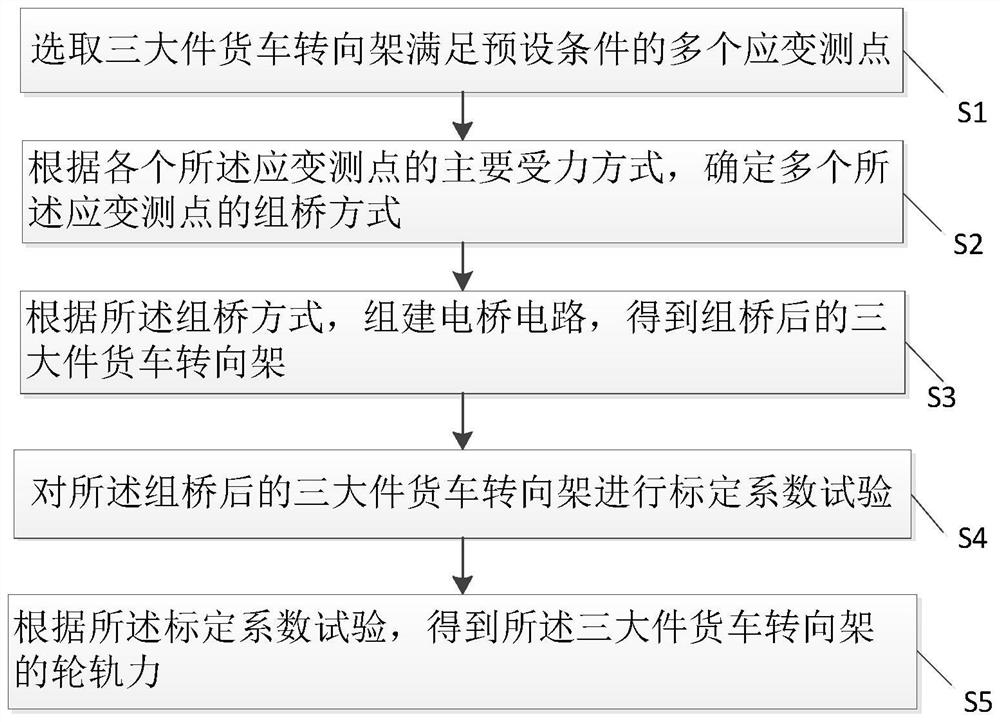

[0049] The invention provides a method for testing the wheel-rail force of a truck bogie with three large pieces. figure 1 As shown, the wheel-rail force test method of the three major truck trucks includes:

[0050] S1: Select multiple strain measuring points of the three major freight car bogies 2 that meet the preset conditions;

[0051] S2: According to the main force bearing mode of each of the strain measuring points, determine the bridging mode of a plurality of the strain measuring points;

[0052] S3: According to the bridge formation method, construct the bridge circuit, and obtain the three large truck bogies 2 after the bridge formation;

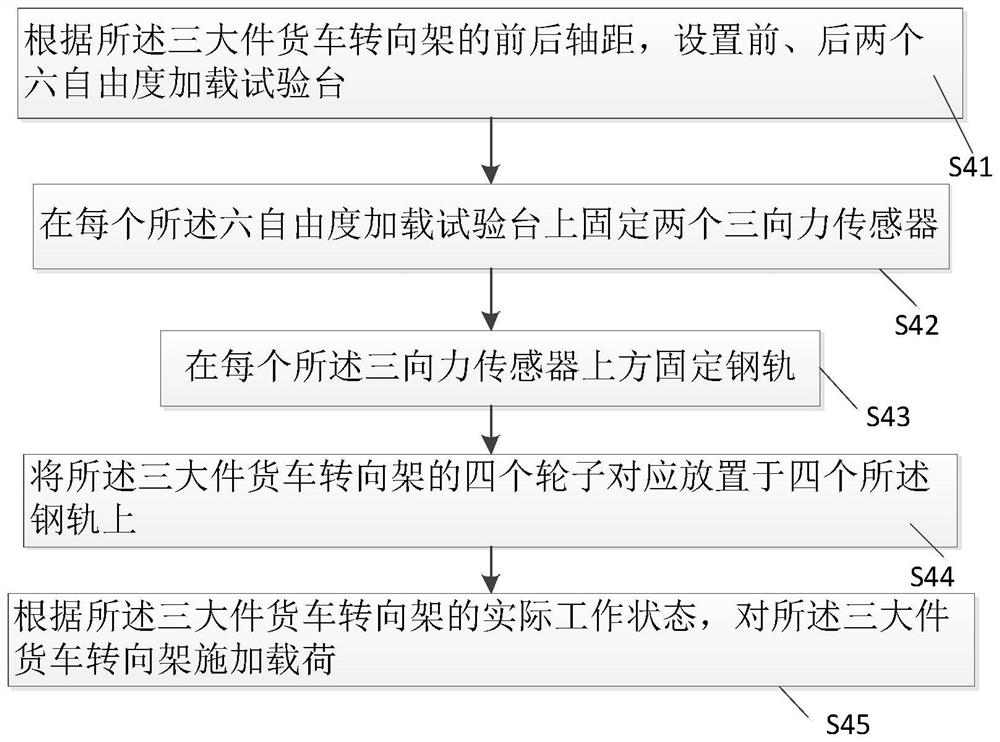

[0053] S4: Carry out a calibration coefficient test on the three major freight car bogies 2 after the bridge assembly;

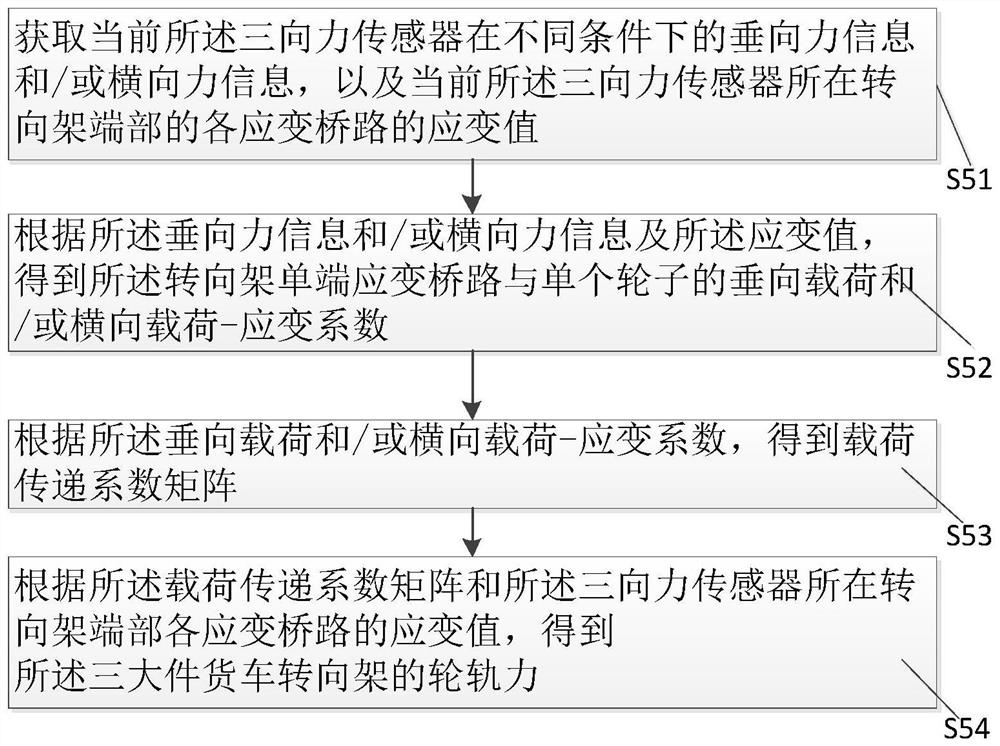

[0054] S5: Obtain the wheel-rail force of the bogie 2 of the three large freigh...

Embodiment 2

[0076] Aiming at the deficiencies of the existing wheel-rail force testing technology, the present invention proposes a method for testing the wheel-rail force of the railway three-piece truck bogie 2 in combination with the structural characteristics of the three-piece railway truck bogie 2, through indirect measurement of the bogie dynamic The contingency method realizes continuous testing of the two-wheel-rail force of the three-size-fits-all freight car bogie. The test performance is stable, the result is reliable, and the production cost is low. It is suitable for the two-wheel-rail force test of the three-large-size freight car bogie.

[0077] The basic principle of the present invention to realize its inventive purpose is: due to factors such as track irregularities, the wheel-rail vertical force and the lateral force change, and the wheel-rail force is transmitted to the bogie through the axle box suspension system, causing the load of the bogie to change, and then The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com