Production process of anti-counterfeiting cigarette tipping paper with flame-retardant function

A production process and a technology for cigarettes, which are applied in the field of cigarette splicing paper production technology, can solve the problems of increased processing difficulty, reduced flame retardant effect, complicated process, etc., to simplify the processing process, improve the extinguishing speed, and reduce the air circulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

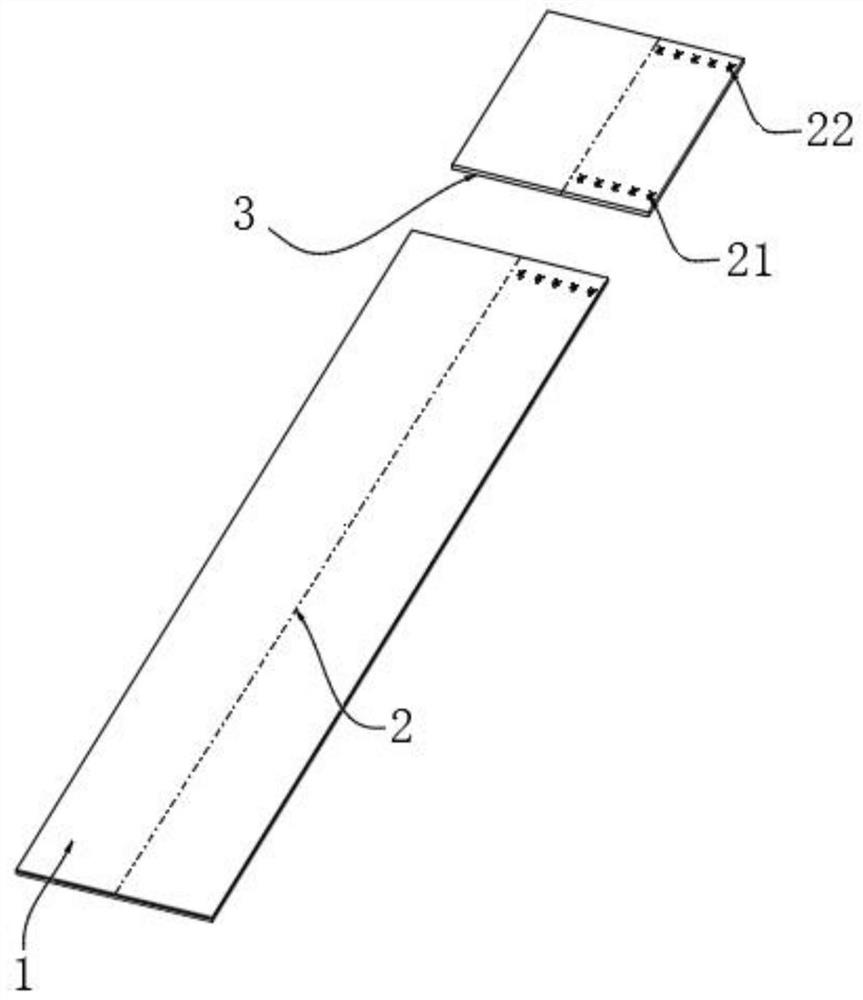

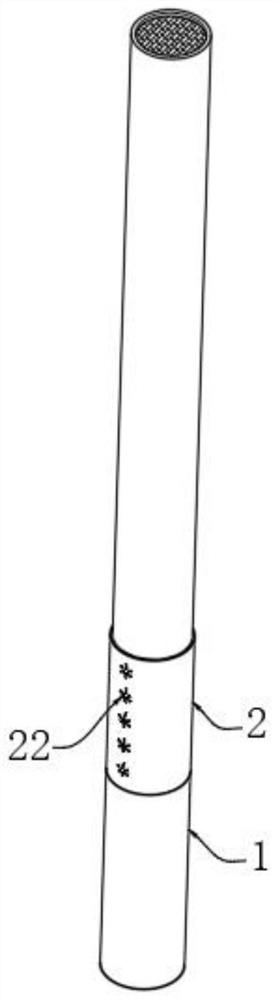

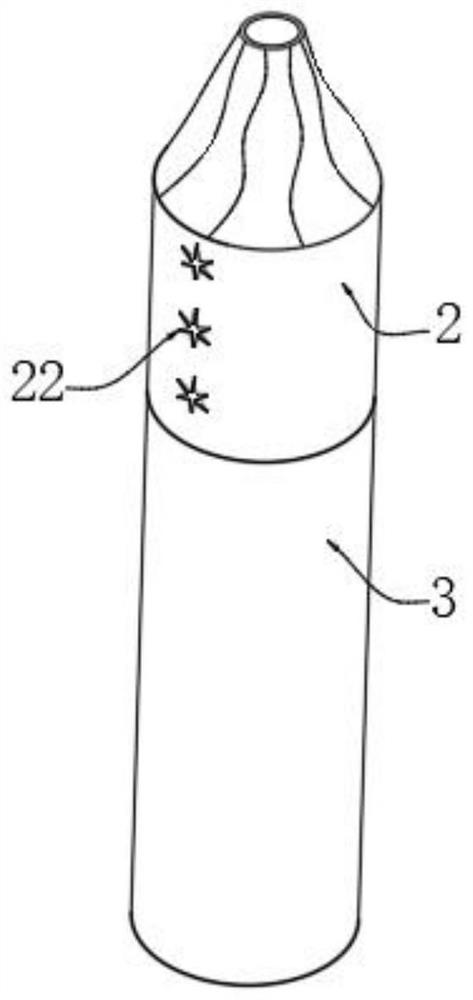

[0029] see figure 1 , figure 2 , image 3 , in the embodiment of the present invention, a kind of anti-counterfeiting cigarette joint paper production process with flame retardant function. 1. The heat-shrinkable layer 2 and the outer layer 3 of the cigarette holder play a connecting role. When surrounded, the base paper 1 surrounds the outside of the filter element and roll paper, and the heat-shrinkable layer 2 and the outer layer 3 of the cigarette holder are located outside the base paper 1. The outer layer 3 of the cigarette holder is mainly for contact with the patient's lips, while the heat-shrinkable layer 2 extends on the filter element to the roll paper part and is bonded and fixed with the roll paper. Move, the temperature at the center of the burning point of the cigarette is 500°C-600°C, and the temperature at the point where the cigarette is lit is about 170°C to 300°C. At this time, when the cigarette is burning to the end, the temperature at the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com