A method for preparing leuprolide by combining solid phase and liquid phase

A technology of leuprorelin and liquid phase is applied in the field of preparing leuprolide by combining solid phase and liquid phase, which can solve problems such as difficulty in large-scale production and inconvenience, achieve high synthesis yield and avoid product instability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

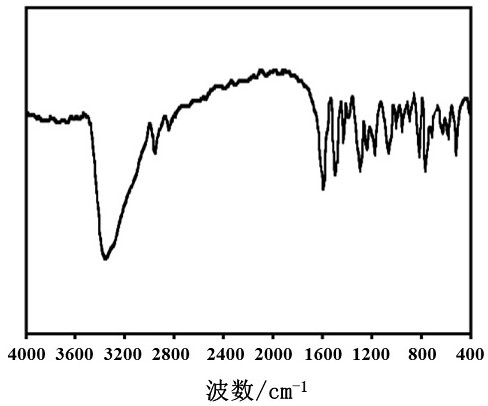

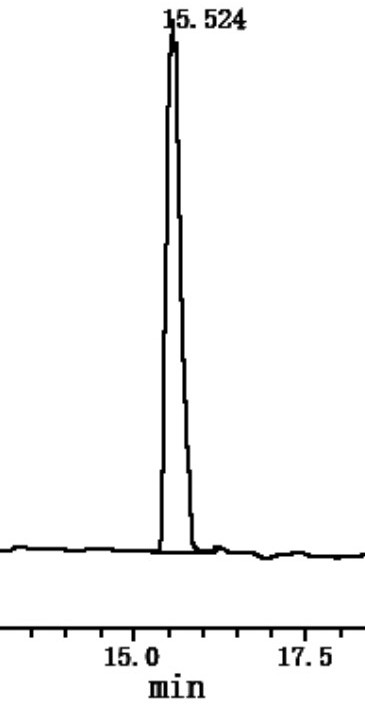

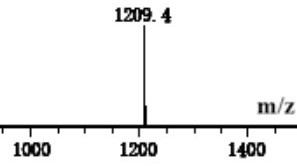

Image

Examples

Embodiment 1

[0078] A method for preparing leuprolide by combining solid phase and liquid phase,

[0079] Preparation of the liquid phase carrier: Add potassium carbonate to DMF, then add 3-ethoxy-4-hydroxybenzaldehyde and 2-(2-ethoxyphenoxy)bromoethane, protect with nitrogen, at 70°C Stir the reaction for 24 h at a temperature of 100 °C, add deionized water to precipitate, filter, wash, and dry to obtain benzaldehyde compounds; under nitrogen protection, add benzaldehyde compounds to the tetrahydrofuran solution, add sodium borohydride, The reaction was stirred at high temperature for 6 h. After the reaction was completed, deionized water was added to the solution to precipitate a precipitate, which was filtered, washed, and dried to obtain a liquid phase carrier. The usage amount of potassium carbonate is 1.2 wt% of DMF, the addition amount of 3-ethoxy-4-hydroxybenzaldehyde is 6 wt% of DMF, the addition of 2-(2-ethoxyphenoxy)bromoethane The amount is 9 wt% of DMF, the tetrahydrofuran so...

Embodiment 2

[0094] A method for preparing leuprolide by combining solid phase and liquid phase,

[0095] Preparation of the liquid phase carrier: Add potassium carbonate to DMF, then add 3-ethoxy-4-hydroxybenzaldehyde and 2-(2-ethoxyphenoxy)bromoethane, protect with nitrogen, at 70°C Stir the reaction for 24 h at a temperature of 100 °C, add deionized water to precipitate, filter, wash, and dry to obtain benzaldehyde compounds; under nitrogen protection, add benzaldehyde compounds into the tetrahydrofuran solution, add sodium borohydride, The reaction was stirred at high temperature for 6 h. After the reaction was completed, deionized water was added to the solution to precipitate a precipitate, which was filtered, washed, and dried to obtain a liquid phase carrier. The usage amount of potassium carbonate is 1.2 wt% of DMF, the addition amount of 3-ethoxy-4-hydroxybenzaldehyde is 6 wt% of DMF, the addition of 2-(2-ethoxyphenoxy)bromoethane The amount is 9 wt% of DMF, the tetrahydrofuran ...

Embodiment 3

[0110] A method for preparing leuprolide by combining solid phase and liquid phase,

[0111] Compared with Example 2, the present embodiment is only different in that in the preparation of Fmoc-Arg(Pbf)-Pro-Wang resin, the usage amount of 2-[(3-aminophenyl)sulfonyl)ethanol is DMF 1.9 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com