A welding construction device for building roof steel structure

A construction device and steel structure technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of cumbersome operation, inability to achieve tight fit welding, etc., and achieve the effect of convenient operation, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments; In application, the shape, thickness or height of each component can expand or contract. The embodiments listed in the present invention are only used to illustrate the present invention, but not to limit the scope of the present invention. Any obvious modifications or changes made to the present invention do not depart from the spirit and scope of the present invention.

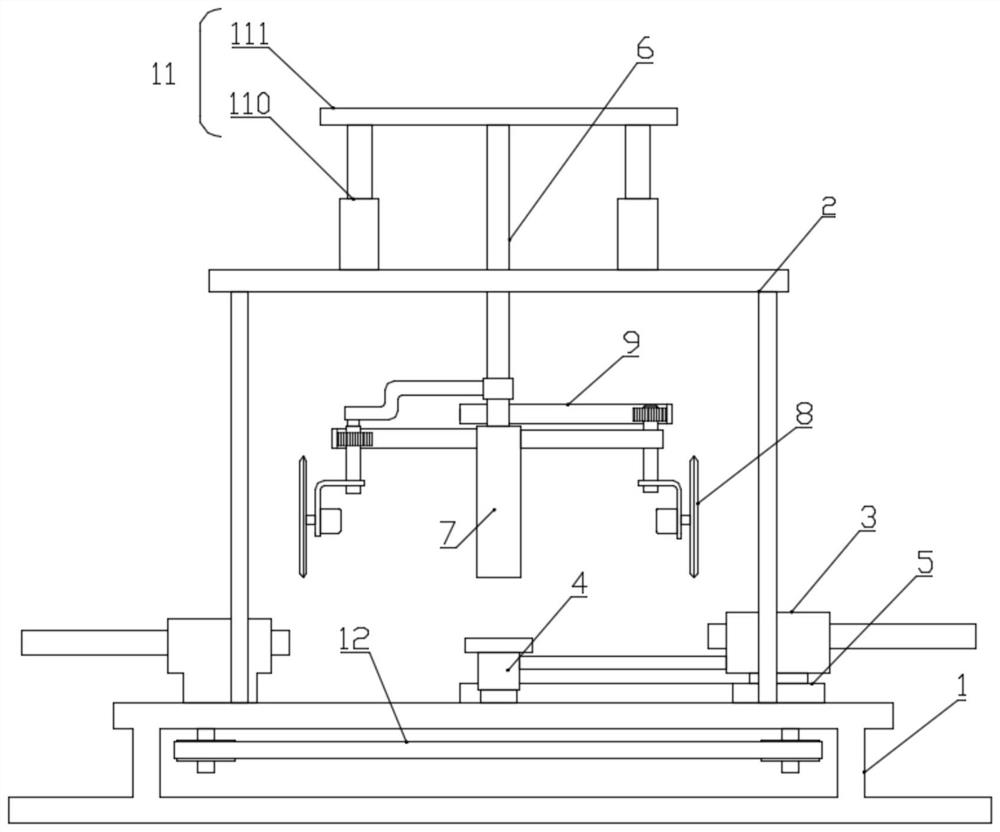

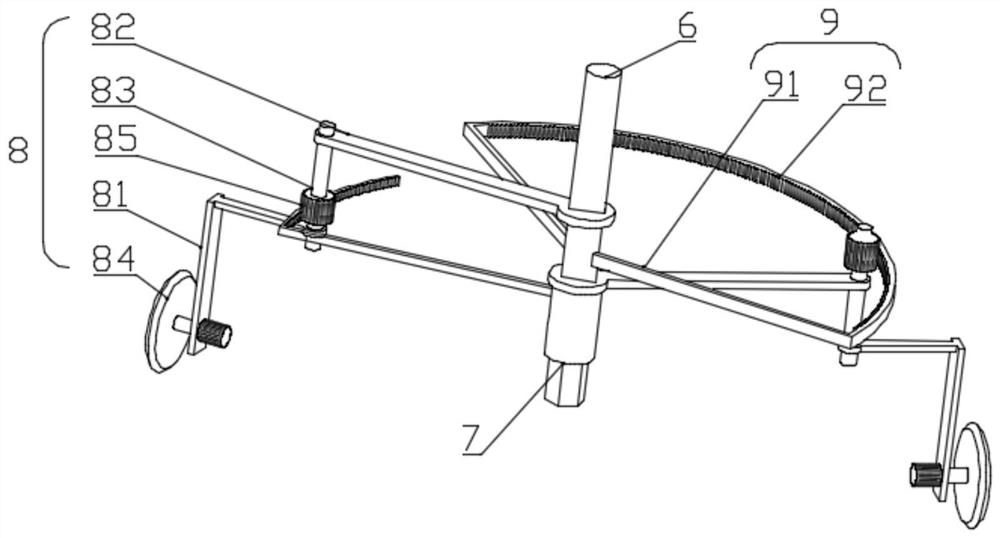

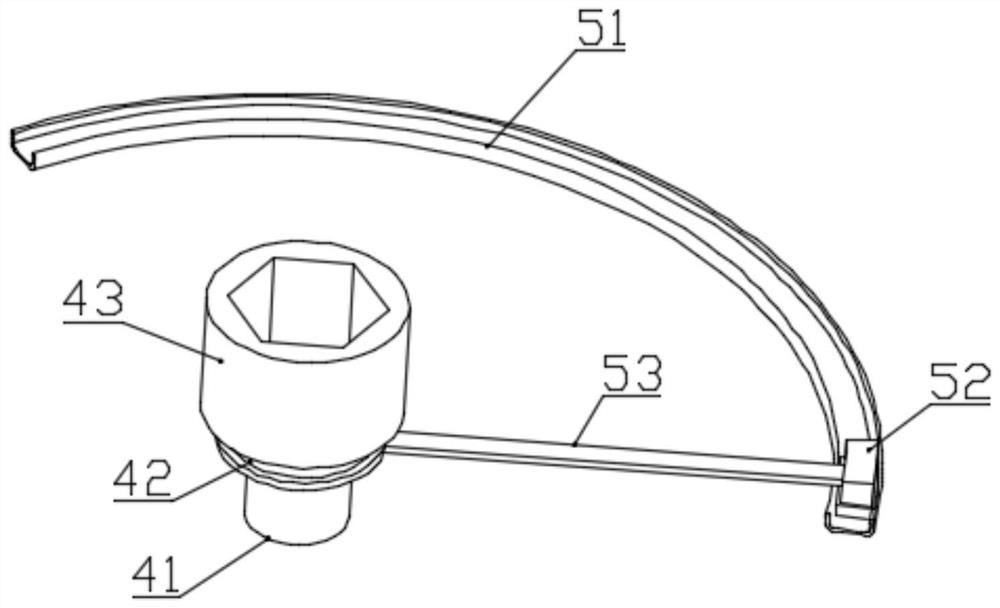

[0024] In one embodiment, as figure 1 and figure 2 As shown, a building roof steel structure welding construction device includes a welding construction platform 1, a frame body 2 arranged on the welding construction platform 1, two conveying brackets 3 and two welding openings for cutting the steel structure. The head assembly 8, the frame body 2 is used for supporting and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com