Plaster gluing equipment

A plaster and gluing technology, which is applied in coatings, devices for coating liquids on the surface, and devices for making medicines into special physical or ingestible forms, etc., which can solve unqualified plaster products and inconvenient adjustment of conveying rollers and scrapers , Plaster bottom paper folds and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

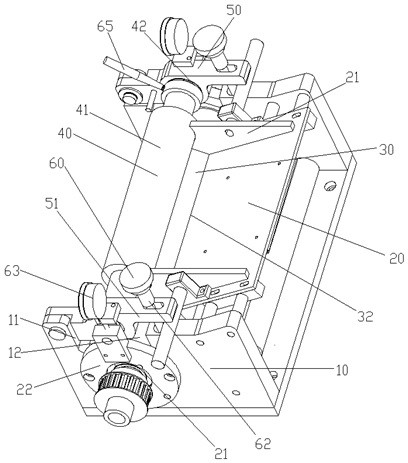

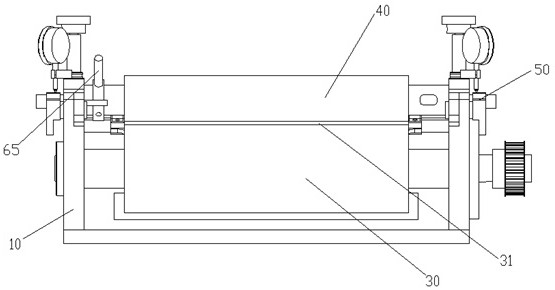

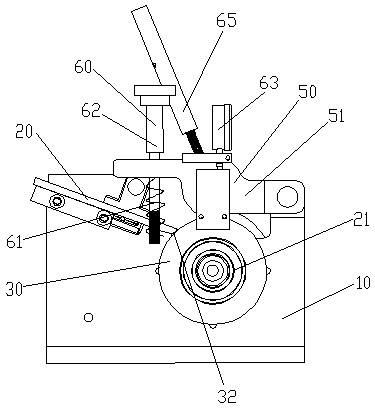

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] Such as Figure 1-Figure 5 As shown, the plaster gluing equipment includes a machine base 10, a conveying platform 20 with a heating function, a conveying roller 30 and a scraping mechanism 40, wherein the conveying roller 30 is rotatably arranged on the machine base 10 by a driving motor, and scrapes The glue mechanism 40 can be placed above the conveying roller 30, and a first gap 31 is left between the conveying roller 30, and the conveying platform 20 is arranged on one side of the conveying roller 30 obliquely, and a second gap is left between the conveying roller 30 32, wherein the end of the conveying platform 20 close to the conveying roller 30 is lower than the end of the conveying platform 20 far away from the conveying roller 30 . Wind the plaster backing paper on the delivery roller 30, place the plaster colloid on the delivery platform 20, rotate the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com