Method for efficiently preparing blueberry concentrated juice with high anthocyanin content

An anthocyanin and concentrated juice technology is applied in the field of efficiently preparing high-anthocyanin-content blueberry juice concentrate, can solve the problems of loss of blueberry aroma, long concentration time, fruit juice change, etc., and achieves attractive color, less time-consuming concentration and rich aroma. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

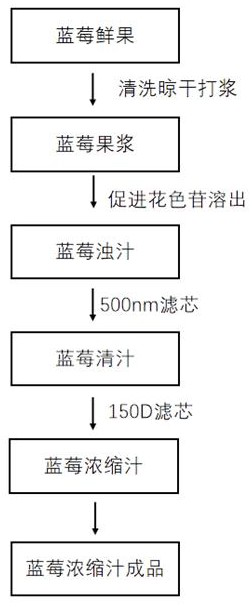

[0027] A method for efficiently preparing concentrated blueberry juice with high anthocyanin content, comprising the following steps:

[0028] Step (1) Cleaning of raw materials: Wash 50kg of fresh blueberries, dry the blueberries with gauze, and place them in room temperature until there are no obvious water droplets on the surface of the blueberries;

[0029] Step (2) beating: Pour the dried blueberries directly into the juicer, and then use the juicer to beat the blueberries evenly;

[0030] Step (3) to promote the dissolution of anthocyanins: add 0.500 wt% pectinase and 0.164 wt% cellulase to the blueberry pulp, enzymolyze it in a water bath at 50 °C for 2.5 h, then place it in a water bath at 100 °C for 5 min to inactivate the enzyme;

[0031] Step (4) Filtration treatment: filter the enzyme-inactivated blueberry pulp with a filter cloth to remove macromolecular pomace, and initially obtain 75L blueberry turbid juice;

[0032] Step (5) adjusting the pH: adjusting the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com