Rapid manufacturing tool for sealing rubber ring pad based on principle of compasses

A technology for making sealing rubber rings and tools, which is applied in metal processing and other directions. It can solve the problems of affecting the sealing performance of sealing rubber ring pads and increasing equipment moisture, and achieves the effects of reducing the probability of moisture, efficient and fast cutting, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

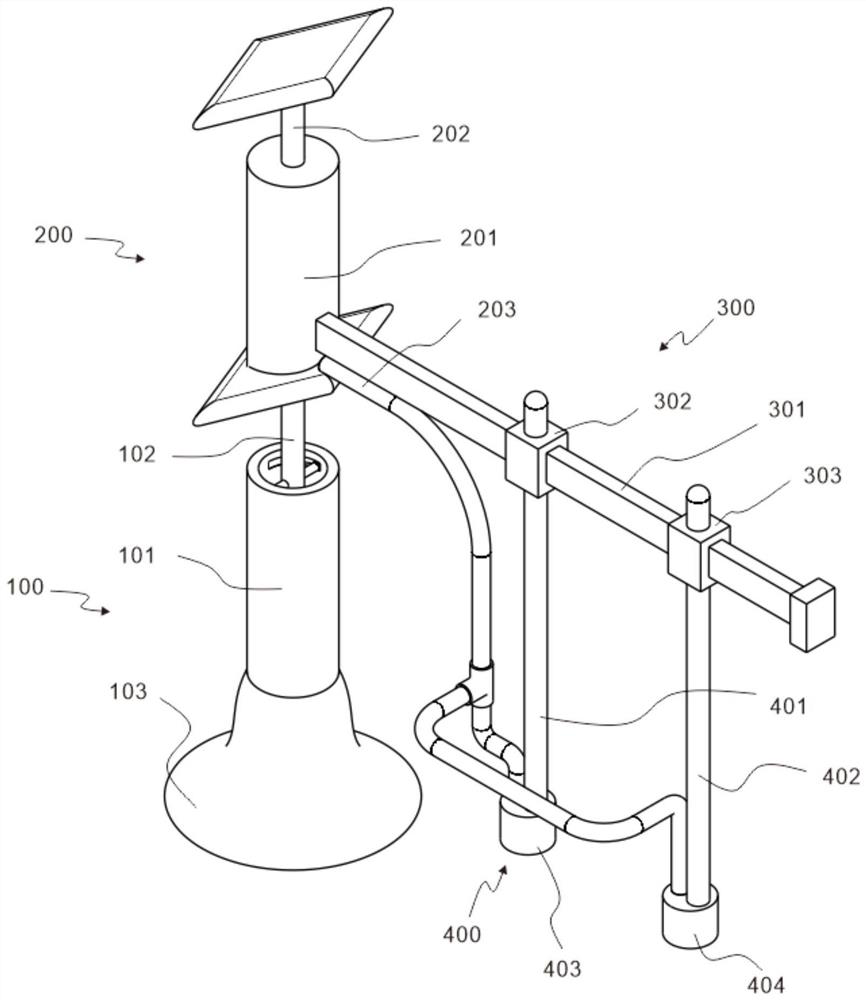

[0029] refer to figure 1 , is the first embodiment of the present invention. This embodiment provides a rapid production tool for sealing rubber gasket based on the principle of compasses. The rapid production tool for sealing rubber gasket based on the principle of compass includes a suction assembly 100 and a compression assembly 200. , the measuring component 300 and the scribing component 400.

[0030] Specifically, the suction assembly 100 includes a suction tube 101, a suction piston 102 disposed inside the suction tube 101, and a suction disc 103 disposed outside the bottom of the suction tube 101. When in use, the suction disc 103 103 is aligned with the rubber surface to be circled. Since the rubber surface is relatively soft, the suction disc 103 is used to fix it on the rubber surface by atmospheric pressure. The suction piston 102 in the suction tube 101 is lifted up, and the gap between the suction disc 103 and the rubber surface Negative pressure is generated an...

Embodiment 2

[0036] refer to figure 1 figure 2 and image 3 , is the second embodiment of the present invention, which is based on the previous embodiment.

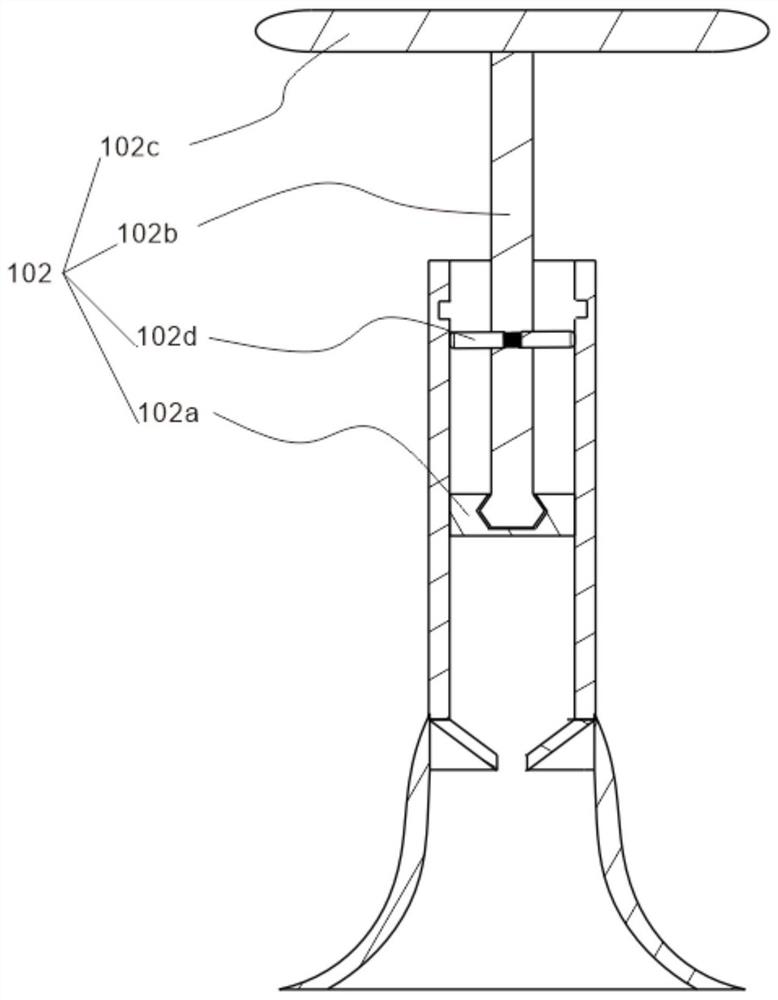

[0037] Specifically, the opening at the bottom of the suction tube 101 shrinks, the inside of the top of the suction disc 103 is fixedly attached to the outside of the bottom of the suction tube 101, the bottom of the suction disc 103 protrudes from the bottom of the suction tube 101, and the suction disc 103 is made of soft materials. The inner wall of the top of the suction disc 103 is bonded to the outer wall of the bottom of the suction tube 101 with glue. When the suction piston 102 in the suction tube 101 is lifted up, the suction disc 103 will naturally expand and become flat under the action of atmospheric pressure, and fit tightly on the glue face.

[0038] Specifically, the suction piston 102 includes a suction piston head 102a, which is arranged inside the suction pipe 101 to closely fit the inner wall of the suction pi...

Embodiment 3

[0044] refer to figure 1 Figure 4 and Figure 5 , is the third embodiment of the present invention, which is based on the first two embodiments.

[0045] Specifically, the No. 1 locking pin 302 is sleeved on the outside of the scale rod 301, including the No. 1 casing 302a and the No. 1 pin 302b. The top of the No. 1 casing 302a is provided with a screw hole, and the No. 1 pin 302b and the No. 1 casing 302a threaded connection, the No. 2 locking pin 303 is sleeved on the outside of the scale rod 301, including the No. 2 casing 303a and the No. 2 pin 303b, and the top of the No. The shell 303a is threadedly connected, and the sleeve shell is sleeved on the outside of the scale bar 301. The pin can move the sleeve shell when it is loose through the threaded hole on the top of the sleeve shell, and fix the sleeve shell when it is tight.

[0046] Specifically, the top of the No. 1 outrigger 401 is welded to the bottom of the No. 1 locking pin 302, the top of the No. 2 outrigge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com