Energy-saving passive power distribution box capable of automatically opening and closing heat dissipation and working method thereof

An automatic opening and closing, passive technology, applied in the direction of separation methods, chemical instruments and methods, substation/power distribution device shells, etc., can solve the problems of poor passive cooling effect, high energy consumption of active cooling distribution boxes, and safety protection performance Low-level problems to achieve the effect of avoiding environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

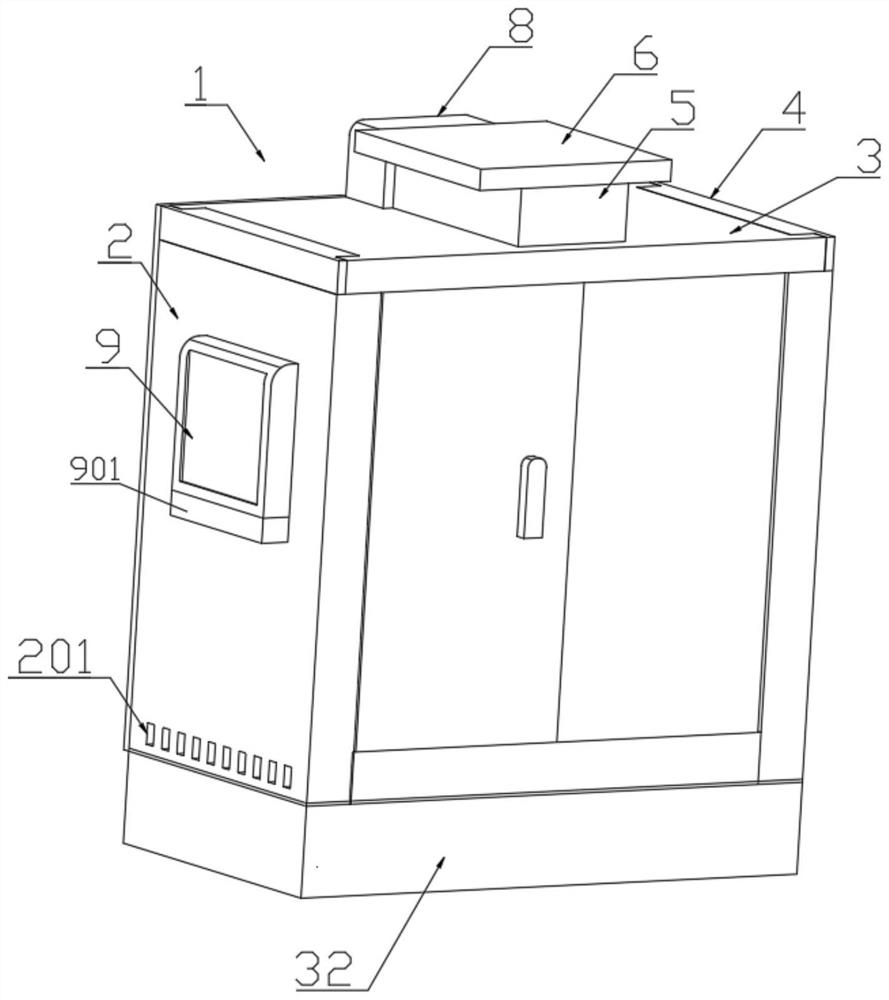

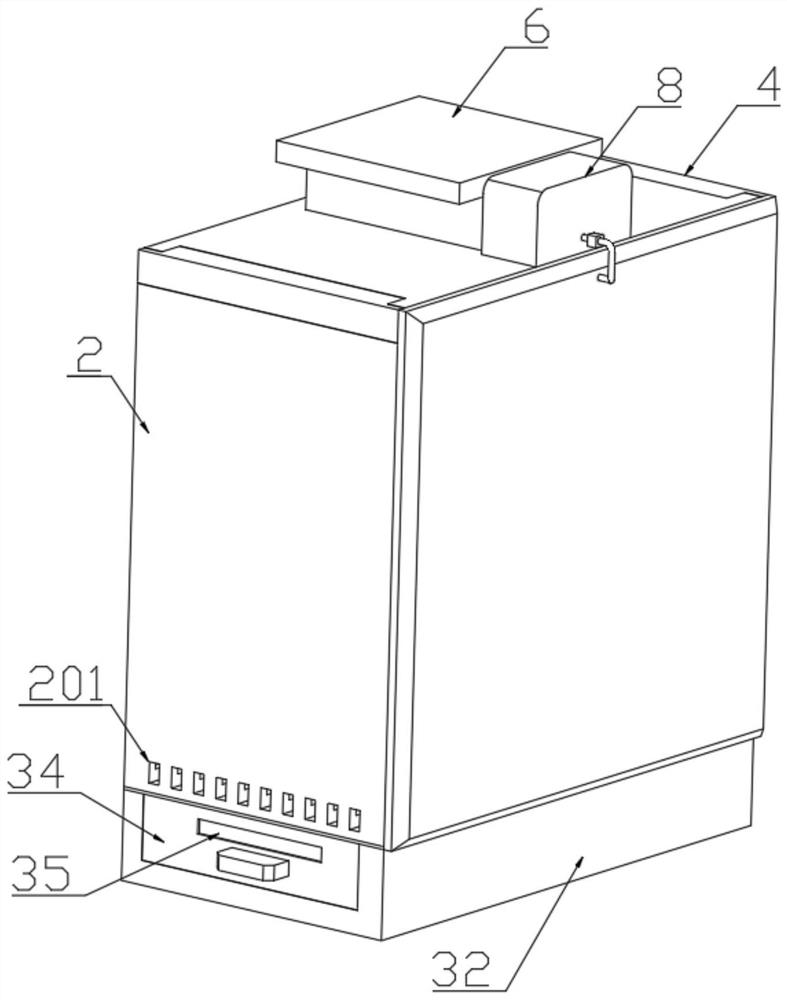

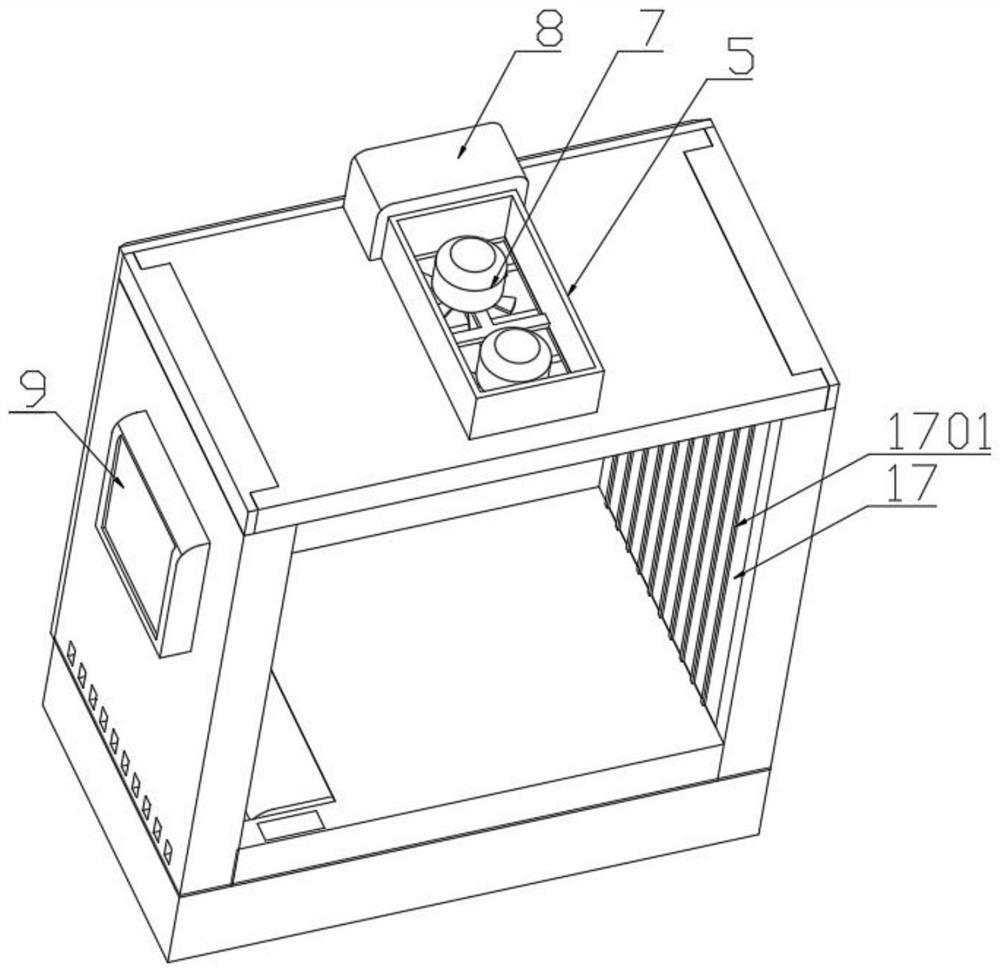

[0037] Such as Figure 1-11 As shown, an energy-saving passive distribution box with automatic opening and closing for heat dissipation includes a passive distribution box 1 and the side plates 2 of the electric box on two sides, the top plate 3 of the electric box and the bottom plate 19 of the electric box, 2. The side plate 2 of the side electric box and the inside of the top plate 3 of the electric box on the top are respectively provided with a side plate evaporation chamber 11 and a top plate air duct 10 connected to each other. The side plate 2 of the electric box located inside the side plate evaporation chamber 11 is installed with a The heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com