Contactor standby stroke test clamp and use method thereof

A technology of test fixtures and contactors, which is applied in the direction of the measuring device shell, etc., can solve the problems of difficult measurement and achieve the effect of convenient operation, simple structure and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] DRAWINGS The present invention will be further described in detail:

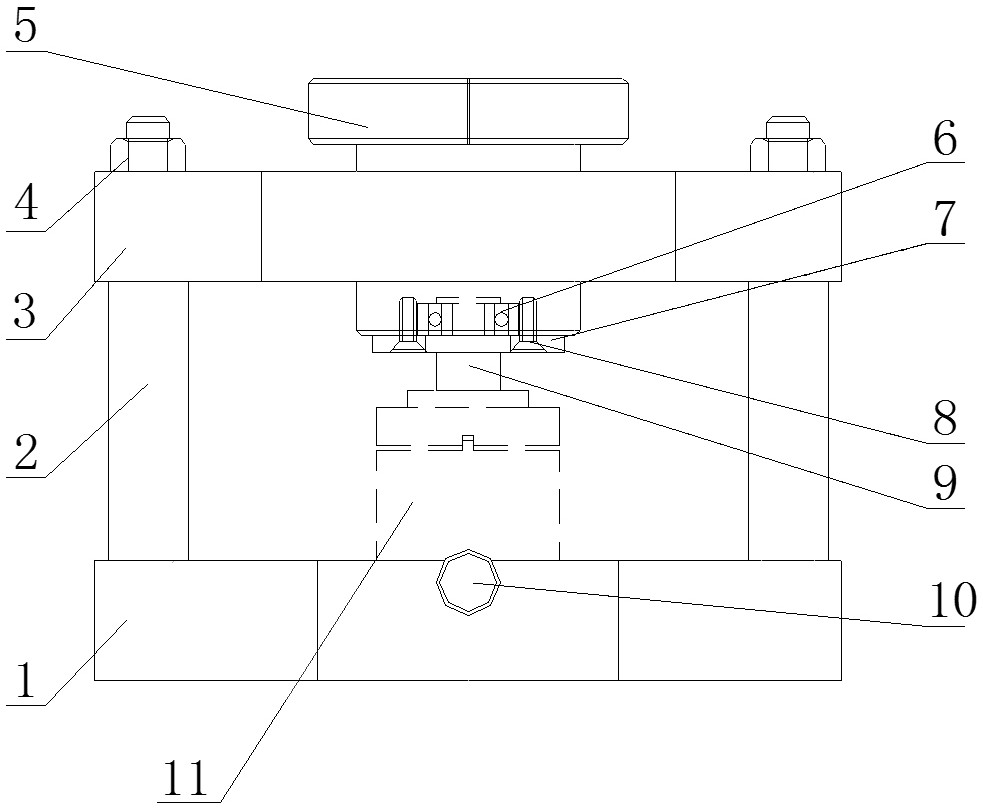

[0028] A touch Spare stroke test fixture, comprising a base 1, column 2, the upper plate 3, a nut 4, a threaded clamps 5, bearing 6, the baffle 7, screws 8, 9 clamps, clamping screws 10, the after the base plate 1 and upper plate 3 are connected by struts 2, and then by a nut 4 is fixed to a solid overall; 3 center position of the upper plate 5 is attached to a threaded compacts, compacts bottom 5 is attached to a threaded bearing 6, the said bottom threaded with compact 5 is fixed by screws 8 baffles 7; 9 mosaic compact while piercing the rear flap 7 is connected to the bearing 6, the bearing 6 purpose is to threaded rotational movement of the clamps 5 compact in the bearing bore 9 6 always linear motion; clamping screw 10 is mounted on the base plate 1.

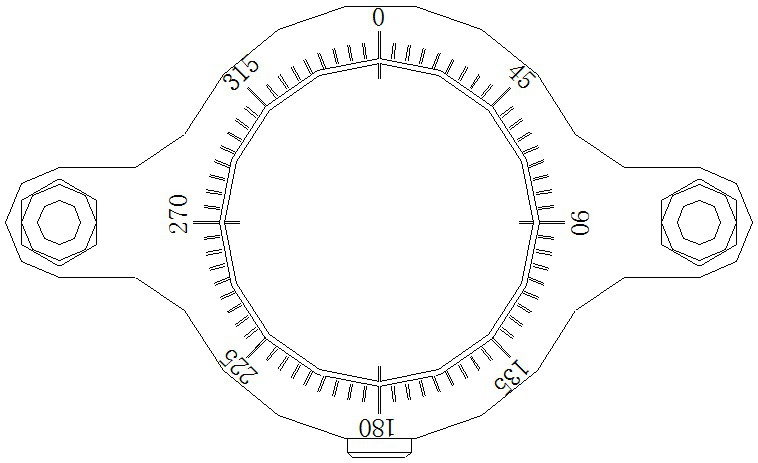

[0029] The present invention utilizes the principle of amplification threaded member, the linear distance from the threaded into curves, thereby measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com