Novel assembly type self-resetting buckling restrained brace device with SMA (Shape Memory Alloy)

A buckling restraint and support device technology, applied in building types, protective buildings/shelters, buildings, etc., can solve problems such as permanent failure, insufficient overall structural rigidity, loss of use function, etc., to improve the rigidity of support structures, assembly The method is quick and easy, and the effect of increasing energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

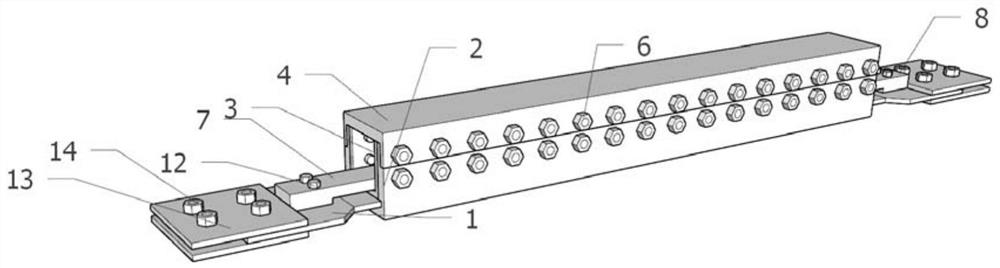

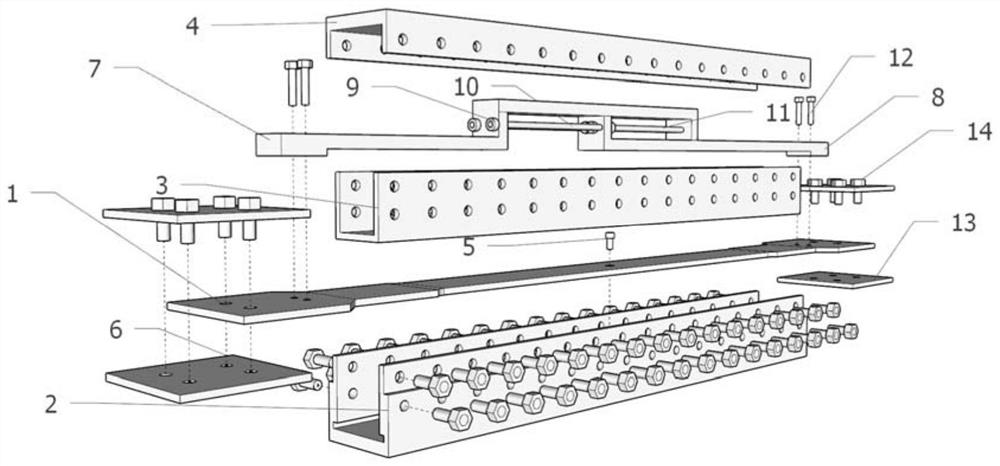

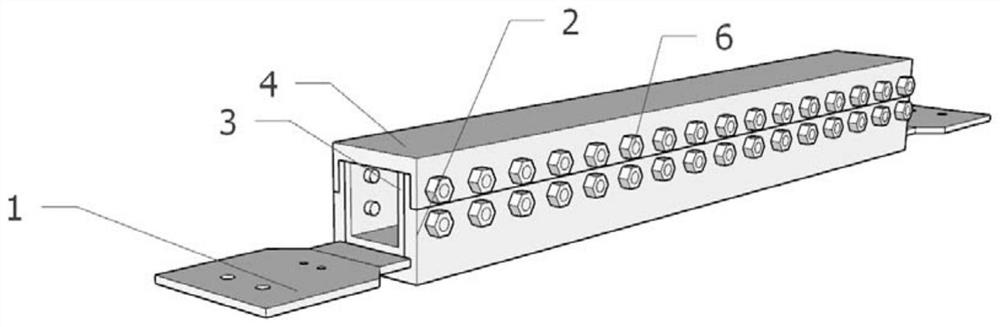

[0034] A new type of prefabricated self-resetting buckling restraint support device with SMA, characterized in that: inline support core 1, outer U-shaped steel 2, inner U-shaped steel 3, several bolts I6, several bolts II12, special-shaped components I7 and special-shaped components II8.

[0035] The U-shaped groove of the outer U-shaped steel 2 accommodates the inline support core 1 and the inner U-shaped steel 3 . The inline support core 1 is a plate-shaped material, and its two ends are connecting end plates 102 located outside the outer U-shaped steel 2 . The upper and lower panels of the inline support core 1 face the inner U-shaped steel 3 and the outer U-shaped steel 2 respectively. The U-shaped notch of the inner U-shaped steel 3 faces away from the inline support core 1, and the U-shaped groove of the inner U-shaped steel 3 accommodates the special-shaped component I7 and the special-shaped component II8.

[0036] The special-shaped member I7 includes a horizontal s...

Embodiment 2

[0039] The main structure of this embodiment is the same as that of Embodiment 1, and further includes a channel steel cover plate 4 . The channel steel cover plate 4 is connected with the outer U-shaped steel 2 and / or the inner U-shaped steel 3 through bolts I6.

[0040] The channel steel cover plate 4 and the outer U-shaped steel 2 form a cylindrical structure, and the special-shaped combination and the inner U-shaped steel 3 penetrate into the inner cavity of the cylindrical structure.

Embodiment 3

[0042] The main structure of this embodiment is the same as that of Embodiment 1. Further, the inline support core 1 is composed of a yielding section 101 in the middle, connecting end plates 102 at both ends, and a transition section 103 connecting the yielding section 101 and connecting the end plates 102.

[0043] The connecting end plate 102 is trapezoidal with openings, and these openings are used for connecting with special-shaped composites and external components.

[0044] The width of the yield section 101 is smaller than the width of the transition section 103 and the connecting end plate 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com