Efficient polyamide yarn elasticizing processing device and production process

A processing device and nylon yarn technology, which is applied in textiles and papermaking, can solve the problems of increasing the cost of nylon yarn, reducing the heating efficiency of the device, and increasing the power consumption of the device, so as to reduce the number of installations, improve efficiency, and reduce power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

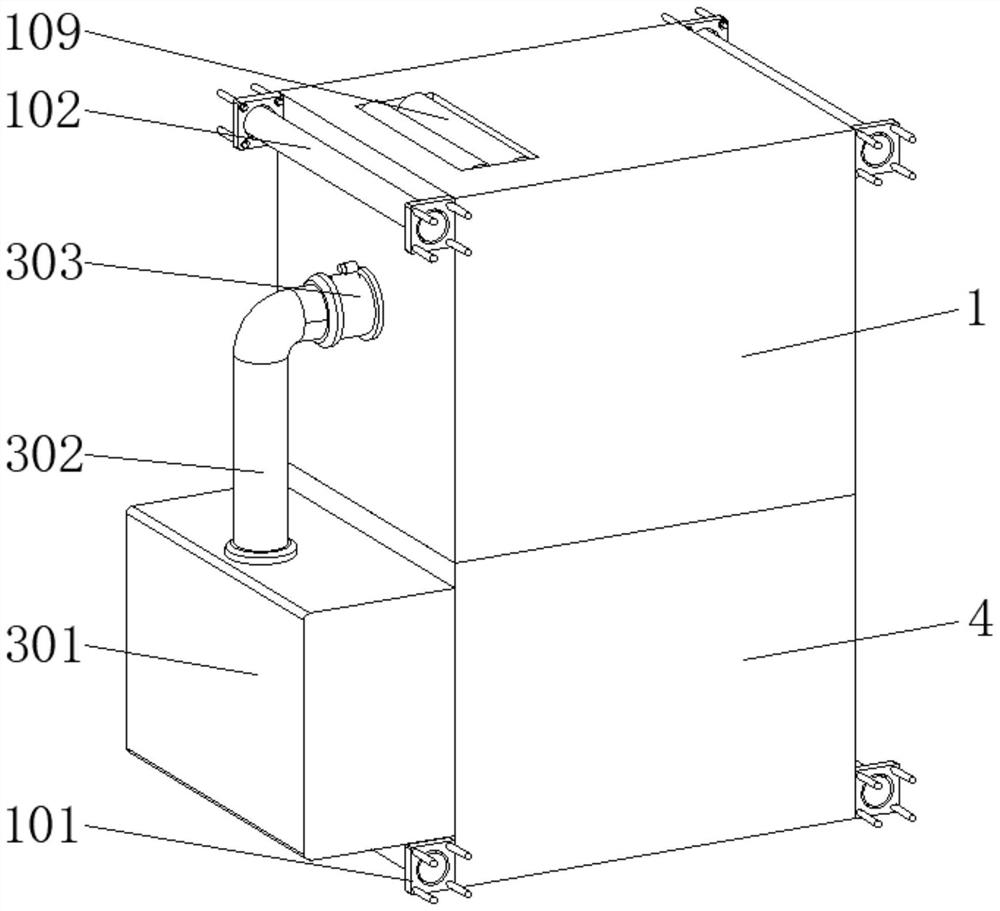

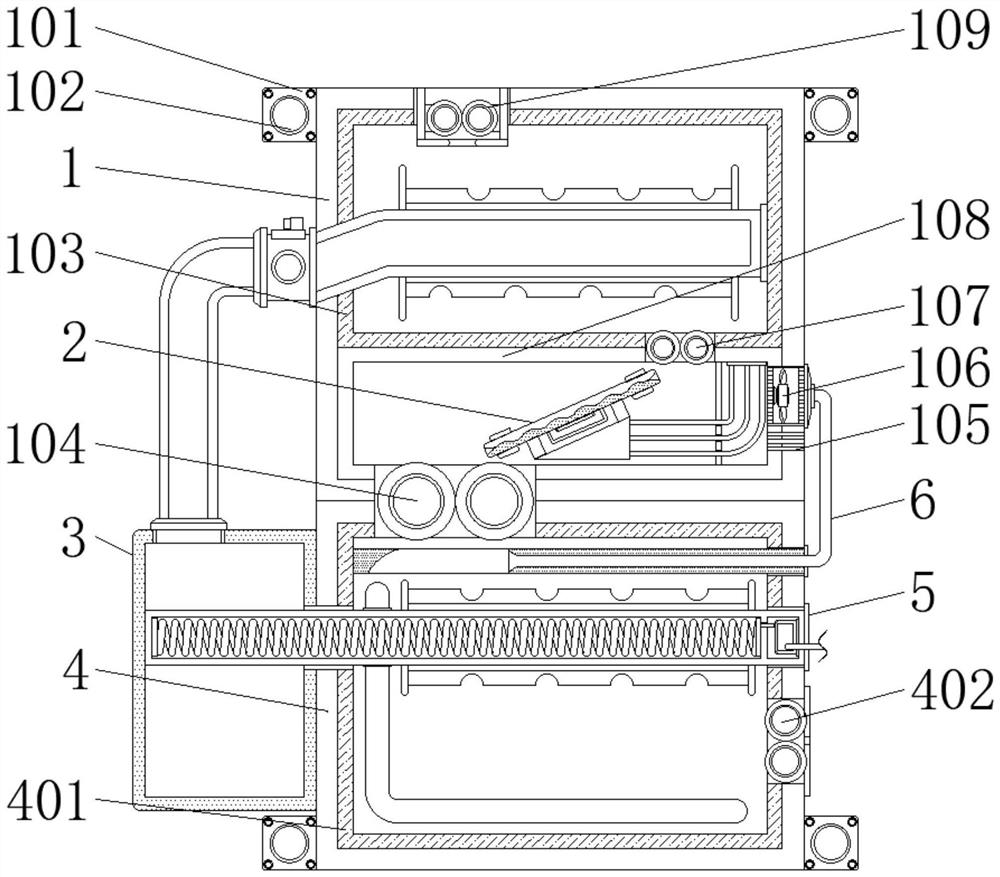

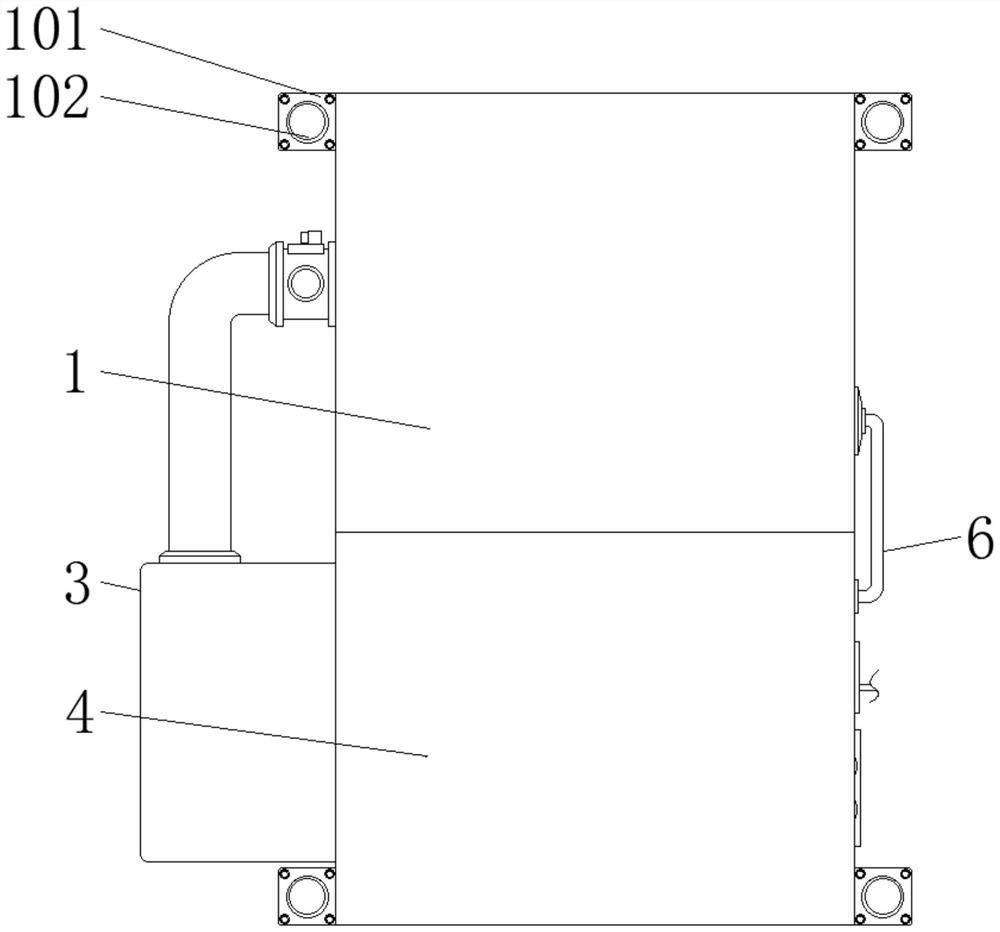

[0035] Such as Figure 1-8 As shown, a nylon yarn high-efficiency texturing processing device proposed by the present invention includes a housing 1, a steam assembly 3, an electric heating assembly 5 and a reflow assembly 6, a heating chamber 103 is installed on the top of the housing 1, and the heating chamber 103 A cooling chamber 108 is installed at the bottom, and a cooling assembly 2 is installed inside the cooling chamber 108. A semiconductor refrigeration plate 201 is installed inside the cooling assembly 2. A bottom shell 4 is welded to the bottom of the housing 1, and an electric heating assembly 5 is installed inside the bottom shell 4. , the installation cylinder 501 is installed in the electric heating assembly 5 , the return assembly 6 is installed above the electric heating assembly 5 , the installation plate 602 is installed in the return assembly 6 , an air guide groove 601 is provided on one side of the installation plate 602 , and one side of the bottom shell...

Embodiment 2

[0041] Such as Figure 1-8 As shown, a nylon yarn high-efficiency texturing processing device proposed by the present invention, compared with Embodiment 1, this embodiment also includes: one side of the cooling chamber 108 is provided with an air inlet 105, and the upper side of the air inlet 105 A heat dissipation fan 106 is installed, a fixed plate 101 is welded on both sides of the housing 1, and a connecting rod 102 is installed on one side of the fixed plate 101, two sets of discharge rollers 109 are installed on the top side of the housing 1, and the housing Two sets of rollers 107 are installed on the inner side of the housing 1, two sets of feed rollers 104 are installed on the bottom side of the housing 1, a limit plate 203 is installed on the top of the semiconductor refrigeration plate 201, and both sides of the bottom of the semiconductor refrigeration plate 201 are installed. There is a clip 206, a silicon wafer 202 is installed on the bottom of the semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com