Tank crawler belt moving support automatic feeding device and conveying system

An automatic feeding and conveying system technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of fixed plate shape limitation, inaccurate grasping of materials, inconvenient use, etc., to reduce exercise intensity, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

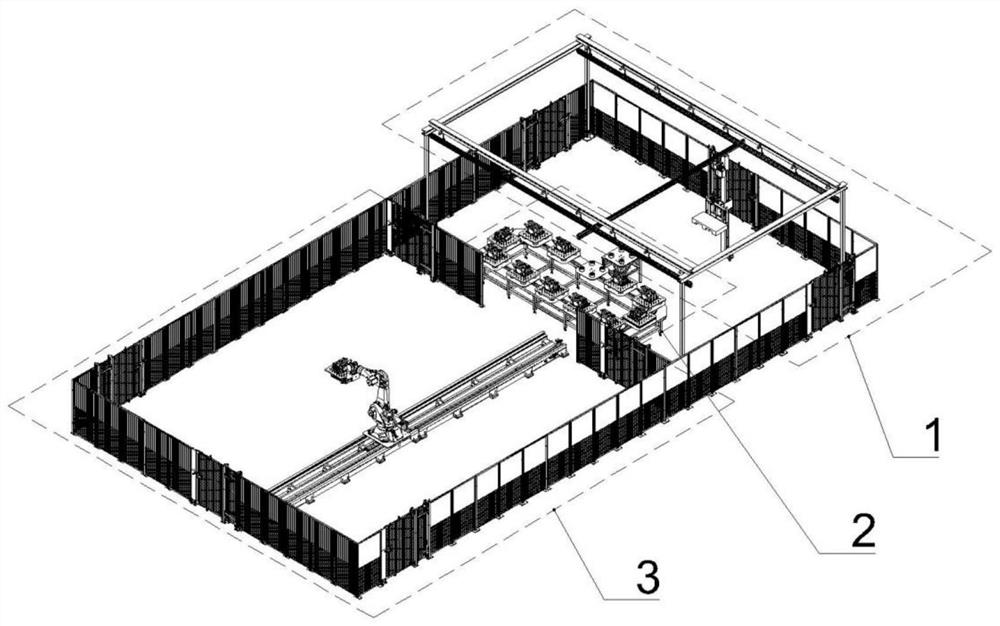

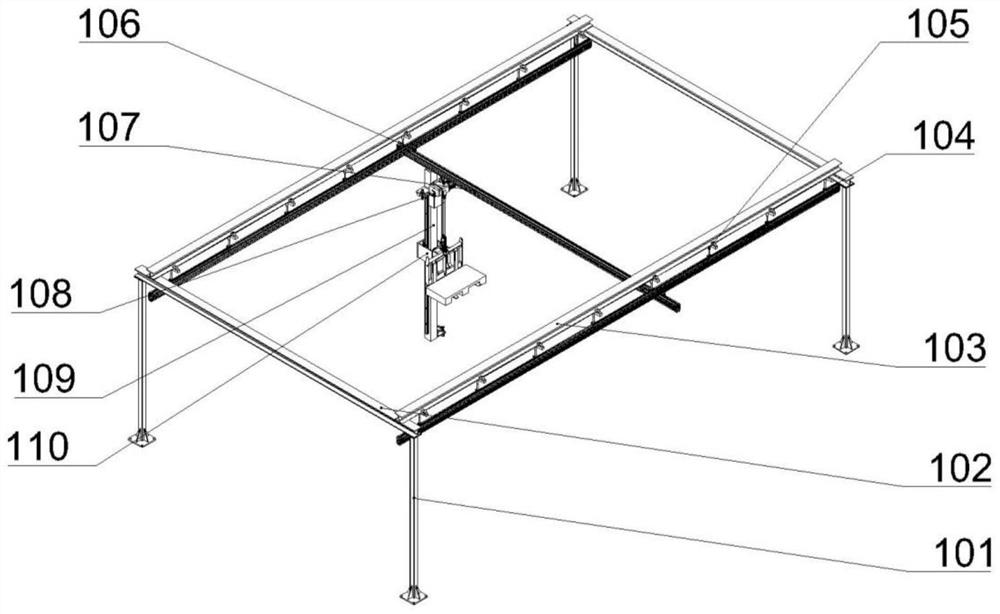

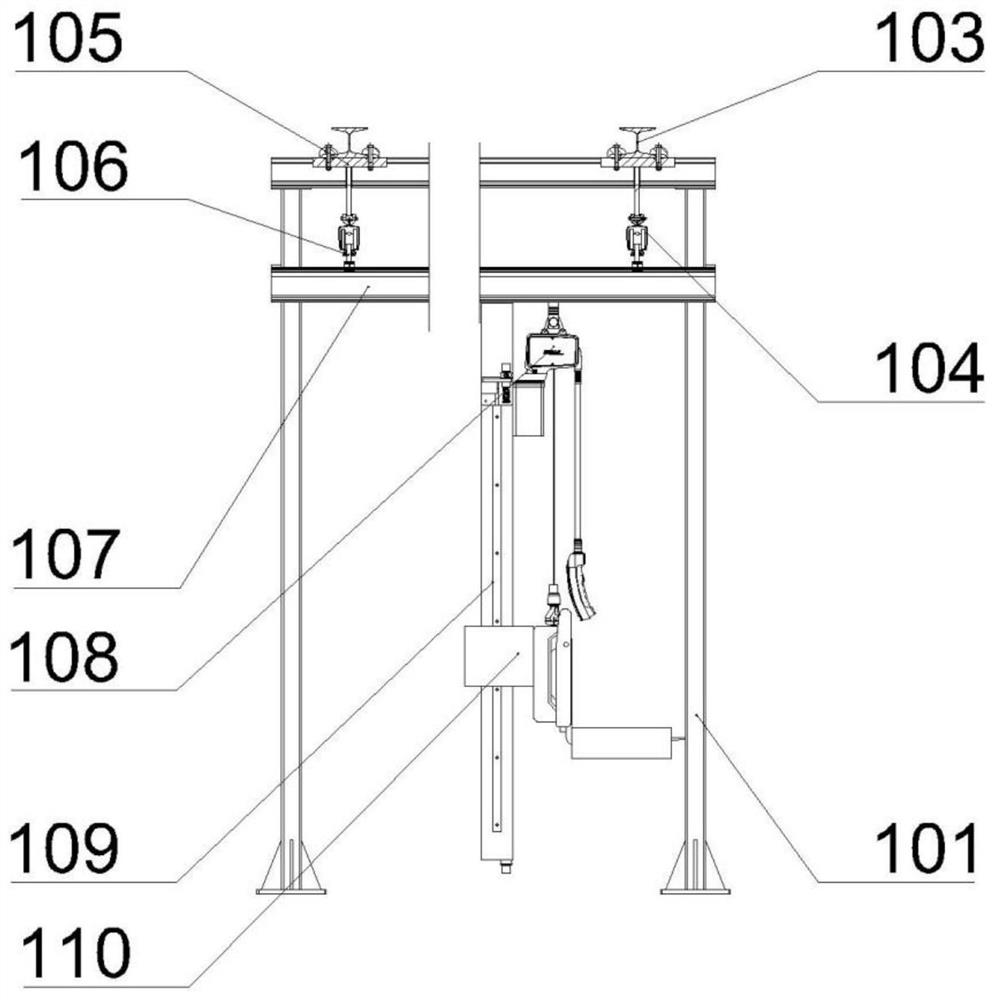

[0051] refer to Figure 1-9 As shown, the present embodiment provides an automatic feeding device for tank crawler action brackets, including an annular conveying line 2, and one side of the annular conveying line 2 is provided with a feeding device;

[0052] The ring conveyor line 2 includes a support frame 201, the top of the support frame 201 is fixedly connected with a bottom plate 202, the top surface of the bottom plate 202 is fixedly connected with a circular guide rail 205, and a plurality of trays 204 are slidably connected to the top of the circular guide rail 205, and the top of the tray 204 is detachably connected with a clamp assembly. Into 4, the bottom of the tray 204 is fixedly connected with an annular driving part to move the tray 204;

[0053] A track-tracking trolley 2041 is fixedly connected to the bottom of the tray 204, and the track-tracking trolley 2041 is slidably connected to the circular guide rail 205, and the ring-shaped driving part is fixedly co...

Embodiment 2

[0065] refer to Figure 10-16 As shown, the difference between the mobile bracket automatic feeding device of the present embodiment and the first embodiment is that the feeding device includes an automatic feeding device 6 positioned on one side of the support frame 201, and the automatic feeding device 6 includes a transport mechanism, and the transport mechanism The side away from the support frame 201 is provided with a screw installation mechanism, and the side of the screw installation mechanism away from the support frame 201 is provided with a clamp assembly mechanism;

[0066] The screw installation mechanism includes a mechanical arm 601 , and the movable end of the mechanical arm 601 is fixedly connected with an inner hexagonal screw driving device 602 and an outer hexagonal screw driving device 603 .

[0067] The clamp assembly 4 is clamped to the mobile support 5 by the clamp assembly mechanism, and then the clamp body 401 is fixed on the tooling plate 402 by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com