Robot two-degree-of-freedom ankle joint structure module

A technology of structural modules and ankle joints, applied in the field of humanoid robots, can solve problems such as high motor torque requirements, low center of gravity of robot legs, complex ankle joint structure, etc., to achieve balance and stability, simple structure, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

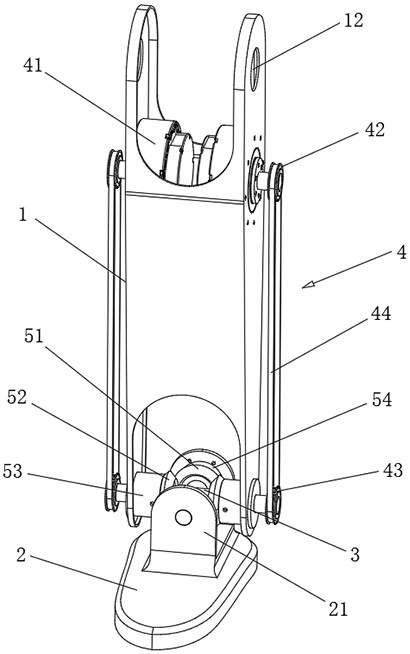

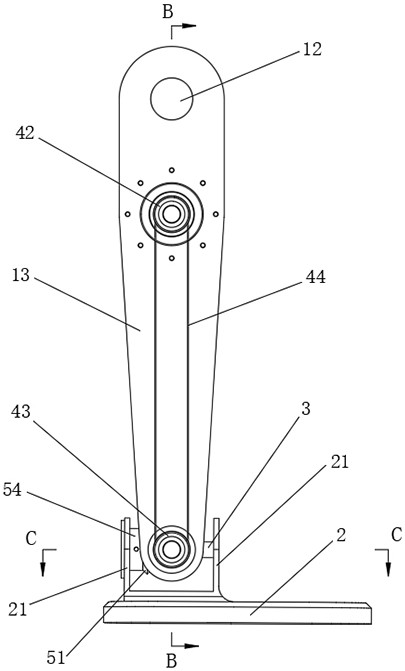

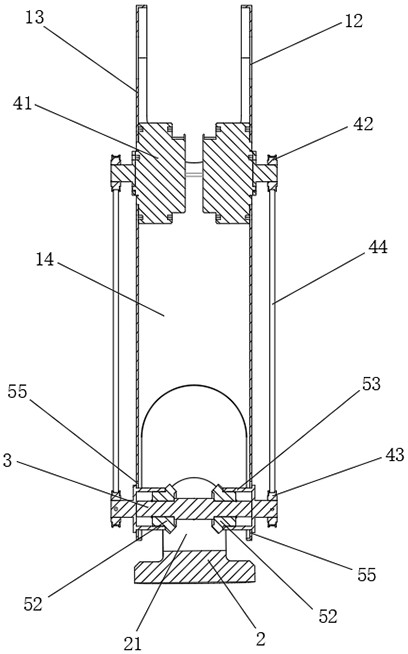

[0037] Embodiment 1, combining Figure 1 to Figure 8 , a robot two-degree-of-freedom ankle joint structure module, including a calf arm 1, a foot 2, a cross connecting shaft 3, a gear assembly and a driving device 4, the foot 2 is arranged under the calf arm 1 through the cross connecting shaft 3, and the cross The longitudinal axis portion of the connecting shaft 3 is rotationally connected with the foot 2 .

[0038] The calf arm 1 is a square tube structure with open upper and lower ends, which includes two long side plates 13 arranged opposite to each other, and the middle parts of the front and rear sides of the two long side plates are fixedly connected by a connecting plate 14 Integrate to form a square tubular calf arm 1, and the calf arm 1 adopts a hollow structure, which is beneficial to reduce its own weight and install components inside it.

[0039] Two knee joint shaft holes 12 are provided symmetrically on the left and right sides of the upper end of the calf arm...

Embodiment 2

[0050] Example 2, combined with Figure 1 to Figure 8 , the working method of the two-degree-of-freedom ankle joint structure module of the above-mentioned robot roughly includes the following steps:

[0051] Step 1: The thigh arm drives the calf arm to move upwards. When the foot leaves the ground, the two servo motors 41 receive instructions from the robot control system to start and determine the rotation direction of the output end of the servo motors 41 .

[0052] Step 2, the servo motor 41 respectively drives the two bevel gears 52 to rotate synchronously, and the rotation direction is opposite, the two bevel gears 52 drive the bevel gear 1 51 to rotate around its axis, and drive the cross connecting shaft 3 to partially rotate around its longitudinal axis After the foot 2 rotates to a predetermined angle around the longitudinal axis of the cross connecting shaft 3, the two bevel gears 2 52 stop rotating, and the foot 2 keeps the left and right inclination angle unchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com