Waxing device for solid wood furniture production

A technology for furniture and solid wood, which is applied in the field of waxing devices for solid wood furniture production, which can solve problems such as inability to use stable supports, and achieve the effects of increasing the overall load limit, expanding the force-bearing area, and reducing space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

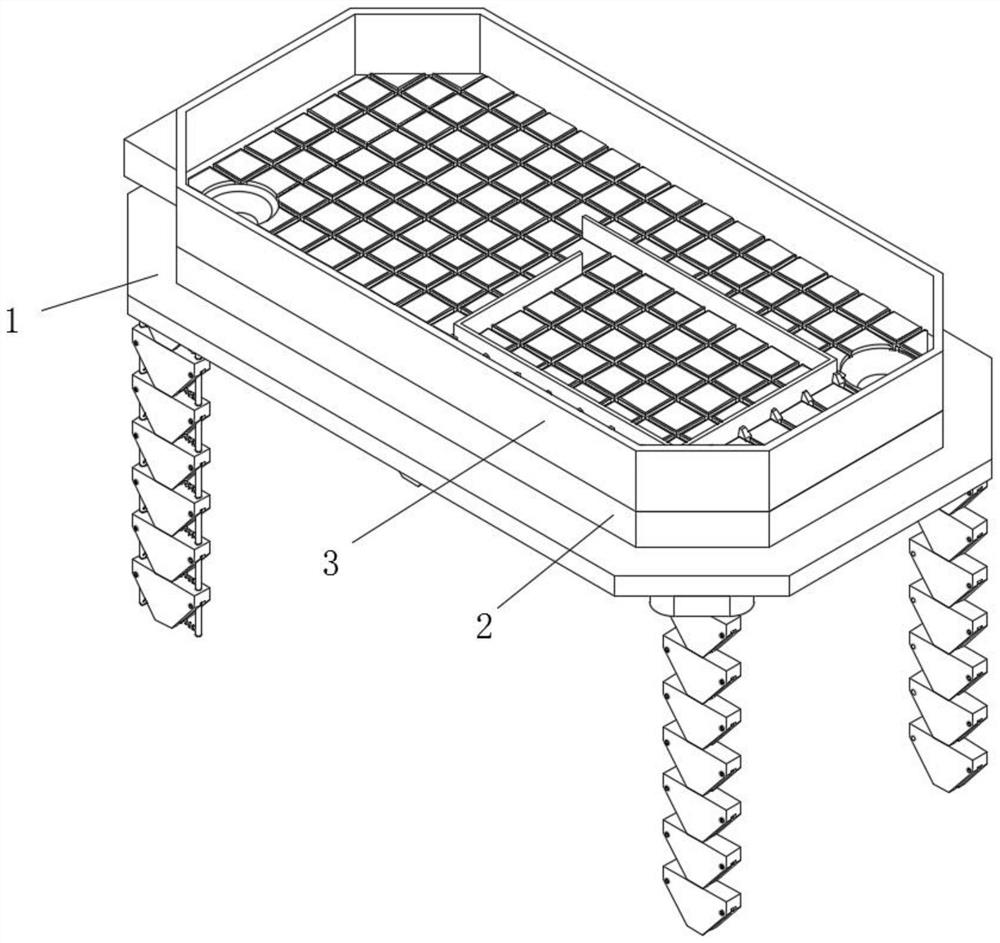

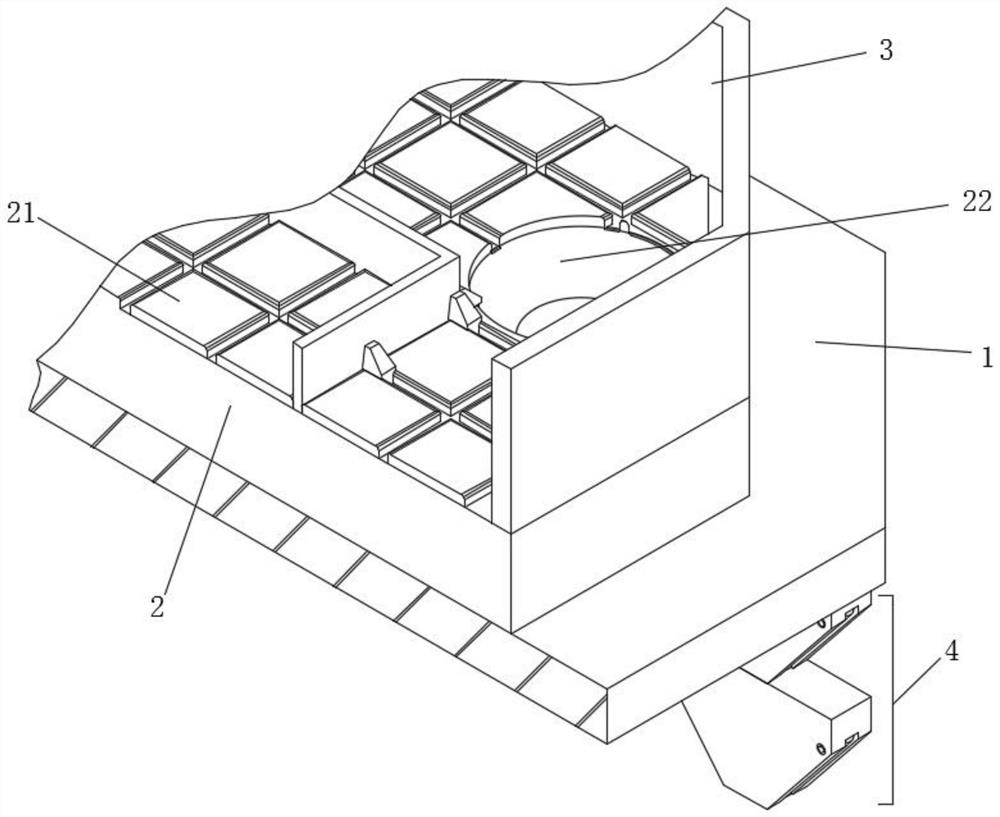

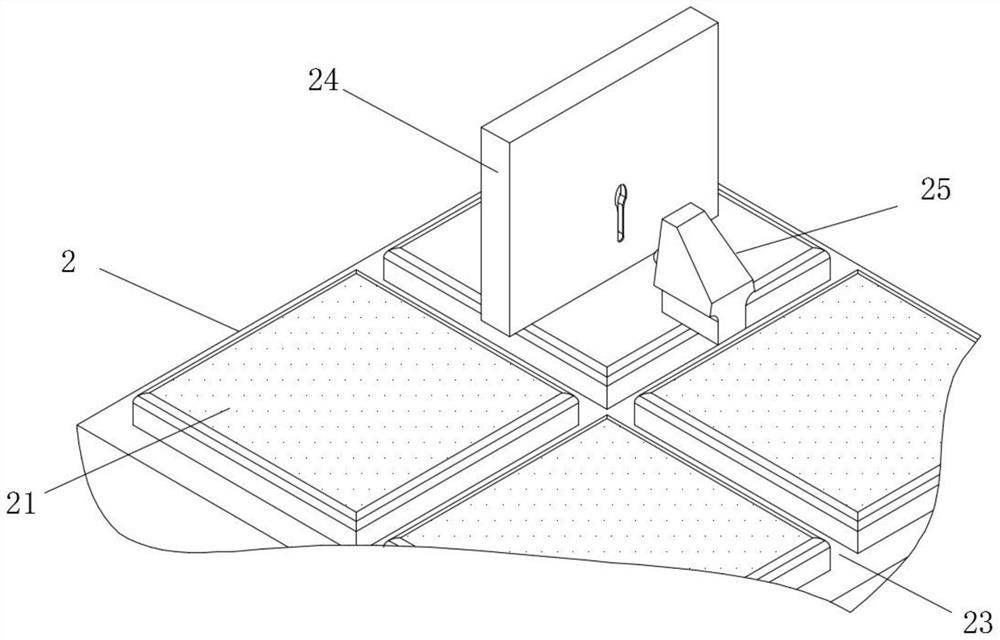

[0027] see Figure 1-6 , the present invention provides a technical solution: a waxing device for solid wood furniture production, including a table board 1, a heating base plate 2 that provides stable heat energy is provided in the middle of the upper surface of the table board 1, and the surrounding surface of the heating base plate 2 is provided with The surrounding board 3 and the four corners of the bottom of the table board 1 are all provided with a foot platform assembly 4 for providing stable support, and the upper surface of the heating base plate 2 is evenly arranged with a number of square blocks 21 for heating wax, and the square blocks 21 are installed. There are molding boards 24 for wrapping furniture with wax materials. The heating base plate 2 is provided with a number of clamping feet 25 for positioning the molding boards 24. The foot platform assembly 4 is stacked with a number of first platforms 41 and second boards. Two platforms 42, the inner side of the ...

Embodiment 2

[0032] Such as Figure 1-6As shown, the present invention provides a technical solution: a waxing device for solid wood furniture production, including a table board 1, a heating base plate 2 that provides stable heat energy is provided in the middle of the upper surface of the table board 1, and the surrounding surfaces of the heating base plate 2 A coaming board 3 is provided, and the four corners of the bottom of the table board 1 are provided with a foot platform assembly 4 for providing stable support. The upper surface of the heating base plate 2 is evenly arranged with a number of grid blocks 21 for heating wax, and the grid blocks 21 A molding board 24 for wrapping furniture with wax is installed on the top, a number of clamping feet 25 for positioning the molding board 24 are arranged on the heating base 2 , and a number of first platforms 41 are stacked on the foot platform assembly 4 And the second platform 42, the inner side of the first platform 41 is installed wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap