Accessory tool rapid locking device and locking method

A fast locking and tooling technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problem of incompatibility of the fitting range, and achieve the effect of wide selection of auxiliary tools, quick operation, and labor-saving operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

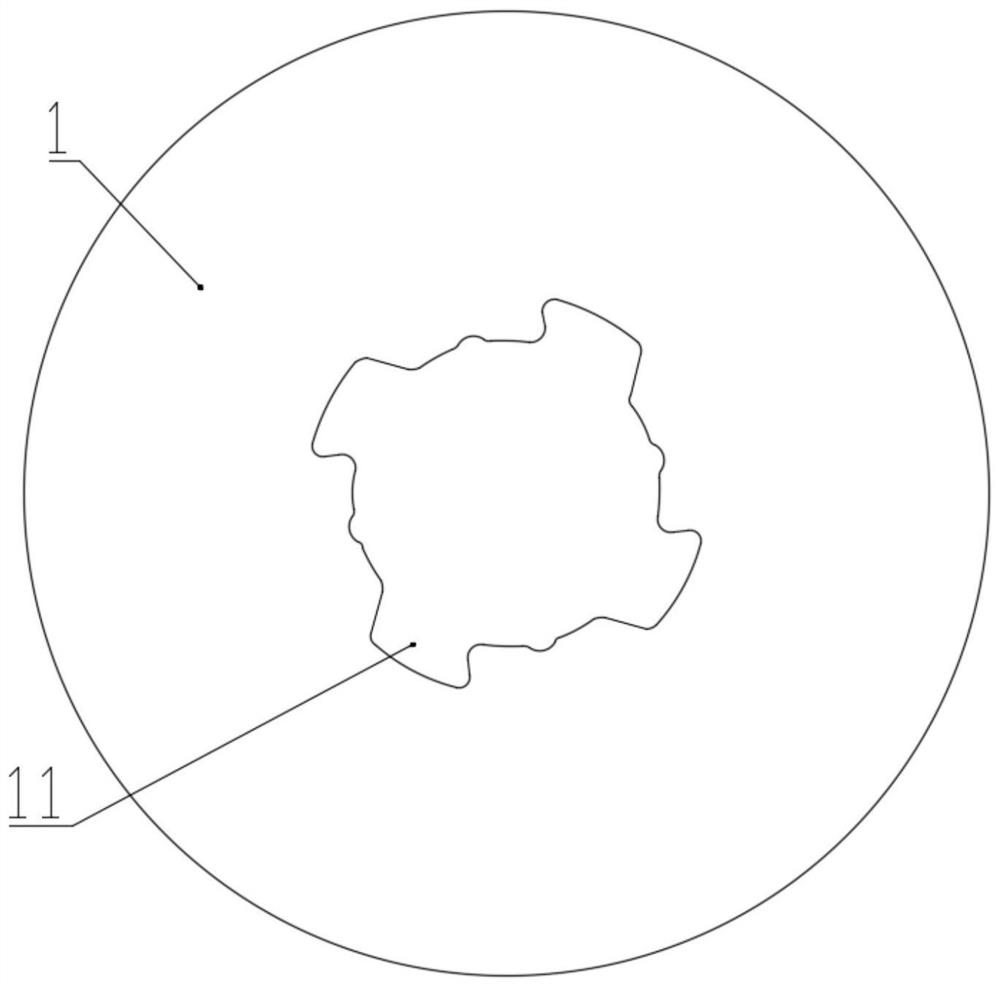

[0057] The center of the grinding section 1 has an accessory tool installation hole, and the accessory tool installation hole can be a round hole or a figure 1 There are several snap-fitting holes 11 that are equidistant and circumferentially distributed around. In this embodiment, the technical solution of this embodiment is described by using the abrasive slice 1 as an accessory tool, but this cannot limit the scope of protection of the present invention.

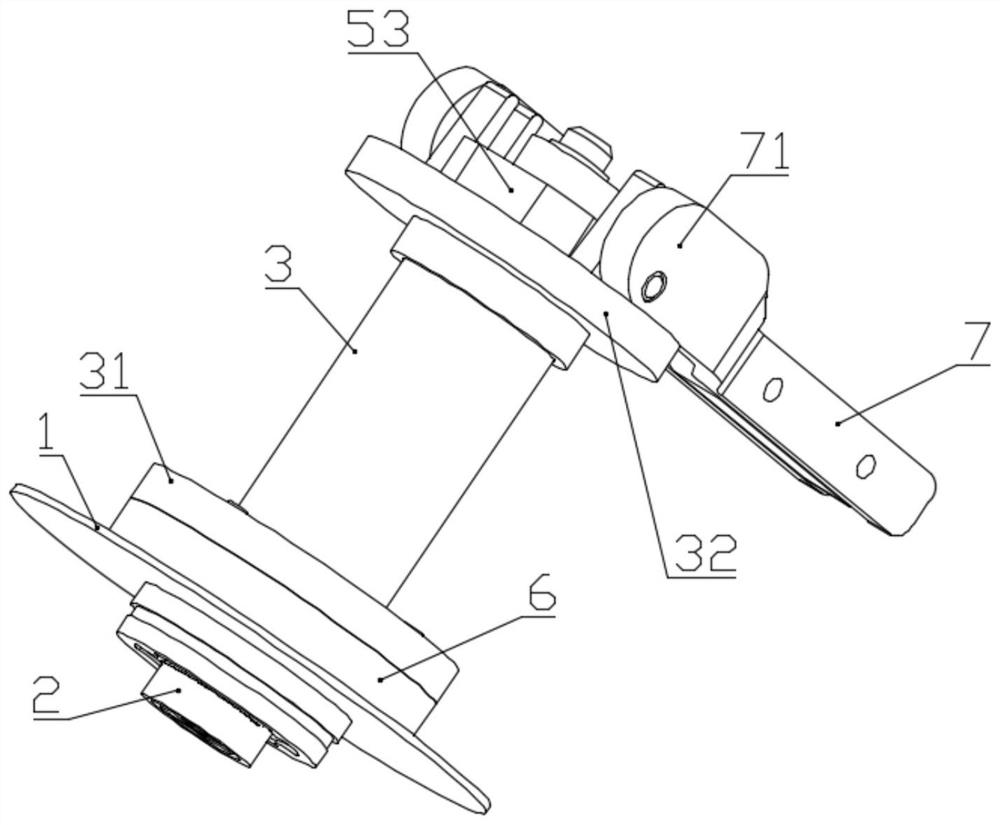

[0058] Such as Figure 2 to Figure 12 As shown: this embodiment discloses a quick locking device for accessory tools: it includes a locking clamping part, a drive transmission part and a support part 3, the drive transmission part include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com