Multifunctional electric grinding machine

A grinding machine and multi-functional technology, applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problems that the anti-corrosion layer cannot be removed quickly, the surface is too smooth, and it is not conducive to anti-corrosion treatment, so as to improve convenience, The effect of good adaptability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

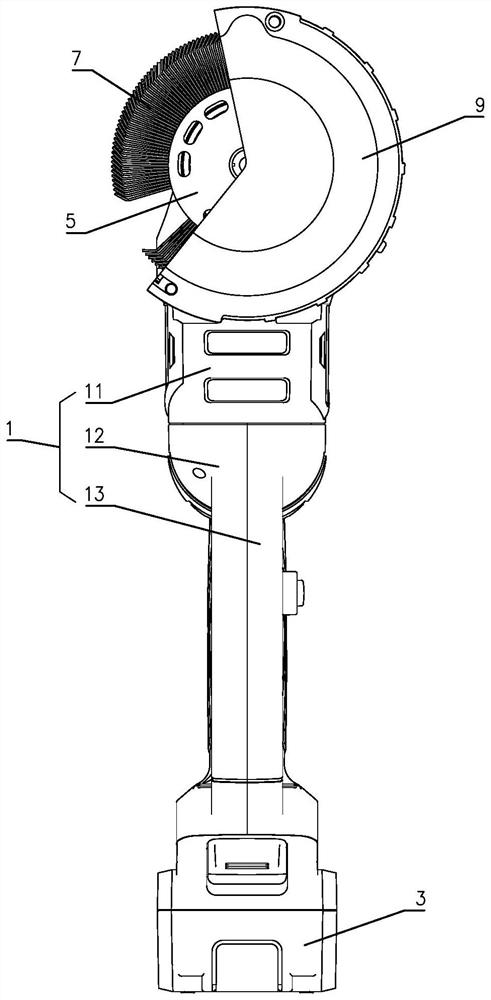

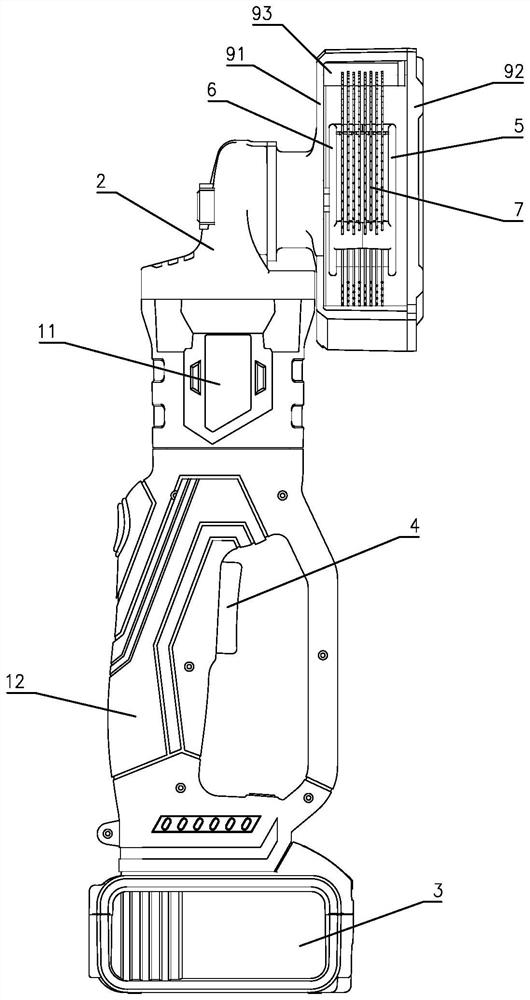

[0038] Such as Figure 1 to Figure 21Shown is a specific embodiment of a multifunctional electric grinder of the present invention, including a main body 1, a motor 2 and a battery 3 are correspondingly arranged at the upper and lower ends of the main body 1, and a control device 4 connected to the motor 2 and the battery 3 is arranged in the main body 1 , the grinding device is installed on the output shaft of the motor 2, so that the grinding device is provided with a front buckling part 5 and a rear buckling part 6 which are engaged with each other, and a front buckling part 5 and a rear buckling part 6 which are clamped betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com