Multi-filling-port sausage filling equipment and sausage filling method

A sausage and equipment technology, which is applied in sausage stuffing machines, mixed meat equipment, slaughtering, etc., can solve the problems of uneven mixing, low filling efficiency, and meat retention, etc., to save equipment space, quickly connect, and change the stirring flow field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

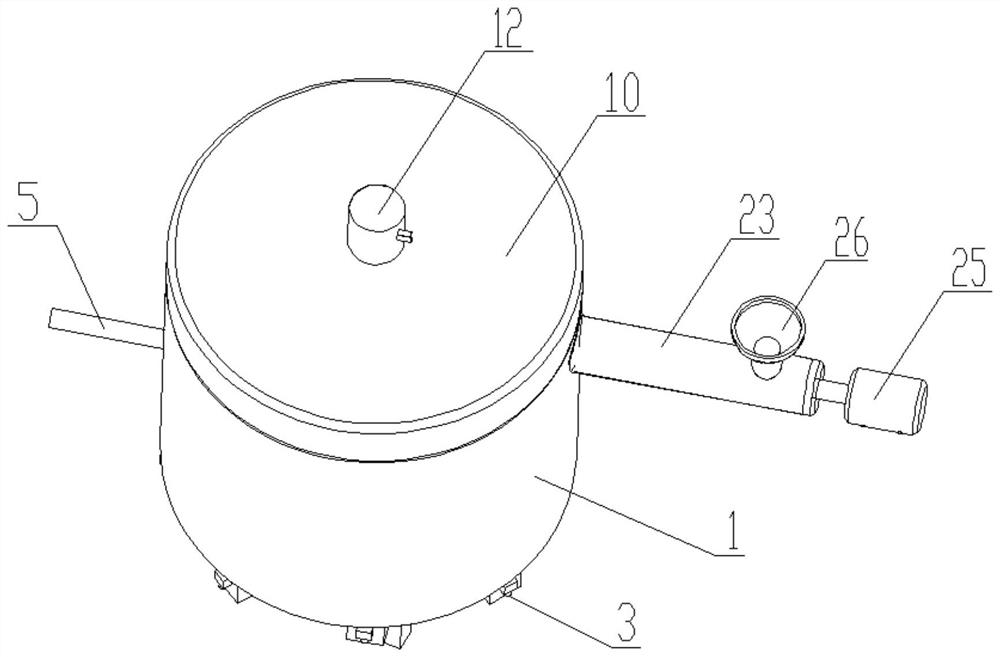

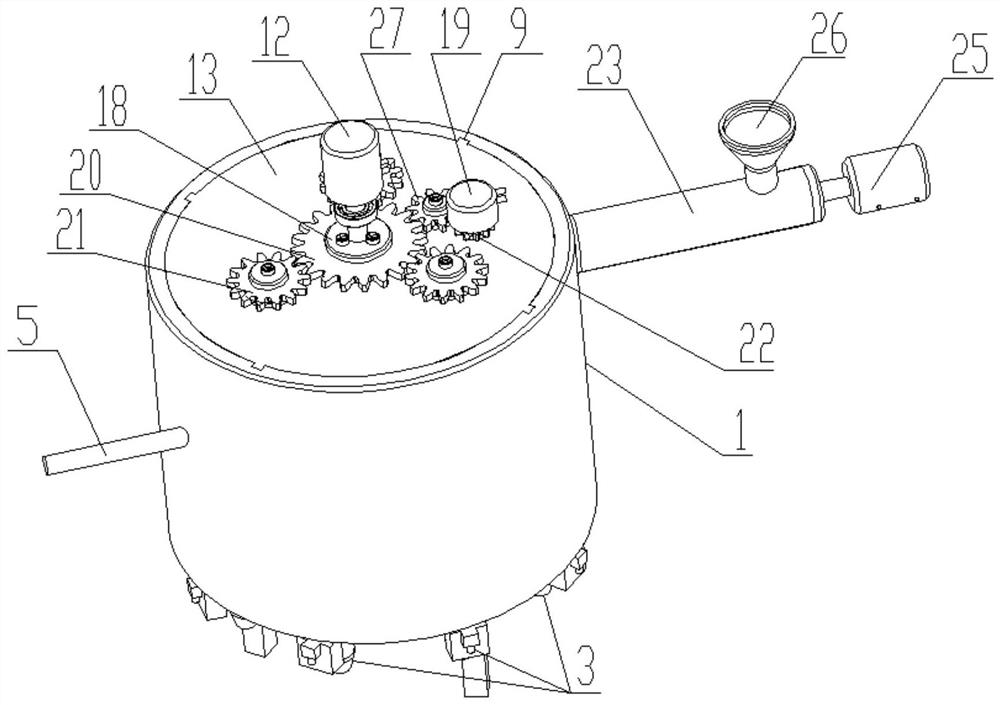

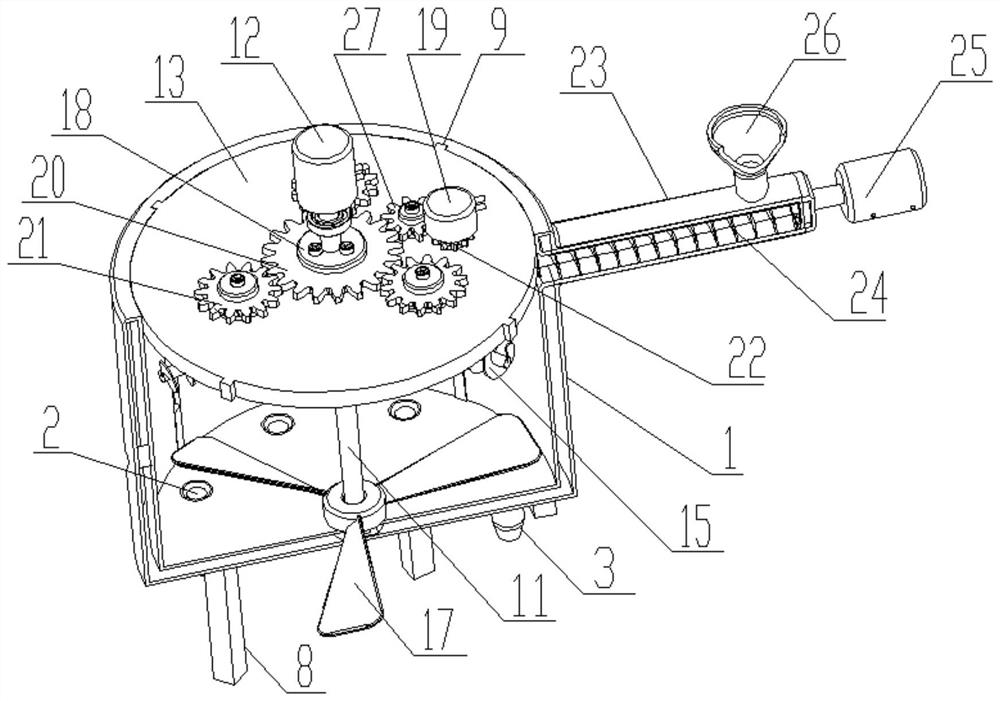

[0036] see Figure 1 to Figure 6 , a sausage filling equipment, comprising a cylindrical tank body 1, the top of the tank body 1 is provided with a cover plate 10, the bottom wall of the tank body 1 is provided with legs 8, the cover plate 10 is sealed and connected with the tank body 1, and the tank body 1 is equipped with a feeding mechanism and eight filling ports 2, and the eight filling ports 2 are evenly arranged on the bottom wall of the tank body 1, and a solenoid valve 3 is installed at each filling port 2, and the outlet of the solenoid valve 3 is used to connect casing casings The side wall of the tank body 1 is also provided with a connecting tube 5 for external vacuuming facilities. After the vacuuming facility is turned on, the inner cavity of the tank body 1 can be vacuumed. The connecting tube 5 should be installed in a convenient and smooth vacuuming area. 1 side wall of the tank body. A stirring mechanism is provided in the tank body 1, and the stirring mech...

Embodiment 2

[0052] A kind of sausage filling equipment, referring to embodiment 1 and combining Figure 7 with Figure 8 As shown, the main difference between it and Embodiment 1 is that a through hole 28 that can pass through the meat material is provided on the helical blade of the second stirring blade 15, and during use, part of the meat material can be passed through a part of the through hole 28 Squeeze side to side to further change the flow field of the meat during mixing.

Embodiment 3

[0054] A kind of sausage filling equipment, referring to embodiment 1 and combining Figure 9 As shown, the main difference between it and Example 1 is that a through-hole 28 for the passage of meat material is provided on the helical blade of the second stirring blade 15, and a spice injection is provided on the cylinder 23 near the outer wall of the tank body 1. Port 4, with such a structure, can completely avoid spices (a small amount of spices will accumulate in the scheme in the embodiment) from accumulating on the inner wall of the cylinder 23, and at the same time, it is beneficial to add spices evenly. This embodiment is a comparison of embodiment 1. Further optimization of the program. In addition, the guide structure 9 includes a groove 30 axially arranged on the inner wall of the tank body 1, the groove 30 is adapted to the rib 29 arranged on the side wall of the pressure plate 13, and a limit block 30 is arranged at the bottom of the groove 30. When moving down, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com