Pressurization type mechanical glue-pouring machine

A glue filling machine and mechanical technology, which is applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve the problems of glue overflow, easy blockage of glue filling ports, and large waste, so as to improve the quality of glue filling and reduce waste of glue , high perfusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

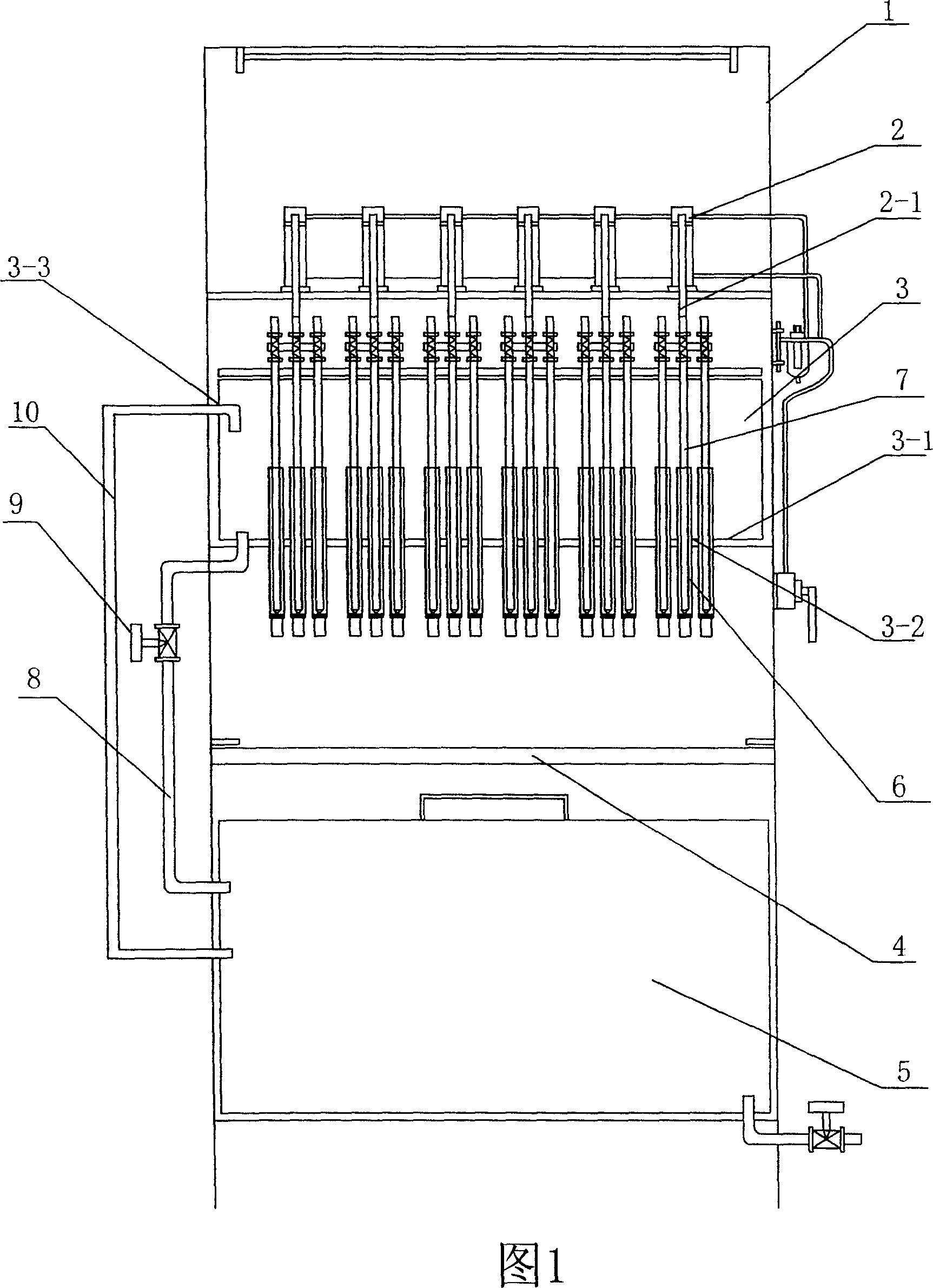

[0011] As shown in the figure, a cylinder 2, a glue storage tank 3, a workbench 4, and an acid tank 5 are arranged on the frame 1 from top to bottom. The free end of the piston rod 2-1 of the cylinder 2 is arranged downward. A rubber feeding pipe 8 is connected between the acid tank 5 and the glue storage tank body 3, and a regulating valve 9 is connected in series to the rubber feeding pipe 8. An outlet 3-3 for controlling the highest level of the colloid is provided on the glue storage tank 3, and an overflow pipe 10 is connected between the outlet 3-3 and the acid tank 5.

[0012] A through hole 3-2 is opened on the lower bottom plate 3-1 of the glue storage box 3, and the through hole 3-2 is sealed and connected to the vertically arranged syringe-shaped acid cup 6, and a pusher is arranged in the syringe-shaped acid cup 6. The upper end of the rod 7 and the push rod 7 is connected with the piston rod 2-1 of the cylinder 2.

[0013] The workbench 4 is arranged below the syringe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com