Method for rapidly measuring oil content of oil stain solid waste

A technology for rapid determination and oil content, which can be used in measurement devices, preparation of test samples, instruments, etc., and can solve problems such as complex detection processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Weigh 100.00g of oily solid waste sample in a glass dish, place it in an oven, and dry it at 105°C until it reaches a constant weight. The weight of the sample after drying is 80.00g. This step takes 20-25 minutes;

[0029] Step 2, weigh 1.00g of the dried oily solid waste sample in a beaker, and add 70ml of spectral grade tetrachlorethylene solution into the beaker, and this step takes 5 to 8 minutes;

[0030] Step 3, add a magnetic stirring bar to the above beaker, place the beaker on the magnetic stirrer, adjust the magnetic field to control the stirring rate to 500rpm and stir for 5min;

[0031] Step 4, use a 0.45 micron organic microporous filter membrane to filter the mixed solution, and rinse the filter bottle with 10ml of spectral-grade perchlorethylene solution each time, for a total of three times, and this step takes 8 to 10 minutes;

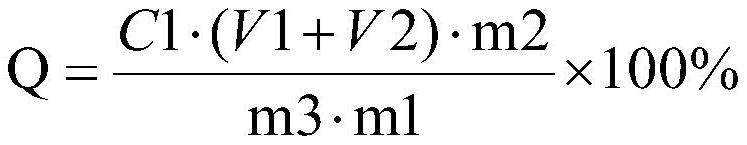

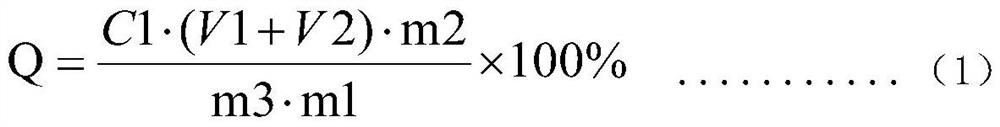

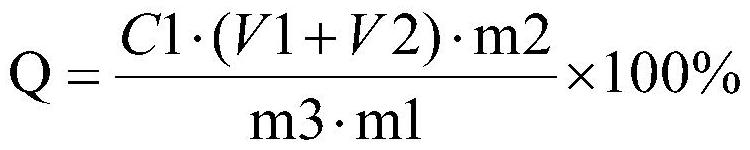

[0032] Step five, take 15ml of the filtered extract in a cuvette, and use infrared spectroscopy at 3400cm -1 ~2400cm...

Embodiment 2

[0037] Experimenters have done five groups of tests according to the present invention, and the test data are as follows:

[0038] Comparison test:

[0039] serial number Standard sample oil content The present invention tests oil content time cost 1 5.00% 4.94% 49min 2 5.00% 4.96% 52min 3 5.00% 4.93% 50min 4 10.00% 9.95% 51min 5 10.00% 9.93% 53min

[0040] This test shows that the present invention can quickly measure the oil content of oily waste and solid waste, and the accuracy of the test results meets the requirements, and can be used for the determination of oily waste and solid waste in actual production.

[0041] The invention discloses a method for quickly measuring oil content, which comprises the following steps: weighing a certain amount of oil sludge and putting it into a drying box, completing the determination of water content and drying of water at the same time, weighing the quantitatively dried sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com