Keycap detection mechanism and detection method capable of effectively preventing pull hook of drawing block from being broken by collision

A detection mechanism and detection method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of drawing block loss, damage, collapsed keycaps, etc., and reduce the detection cost , Improving detection efficiency and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

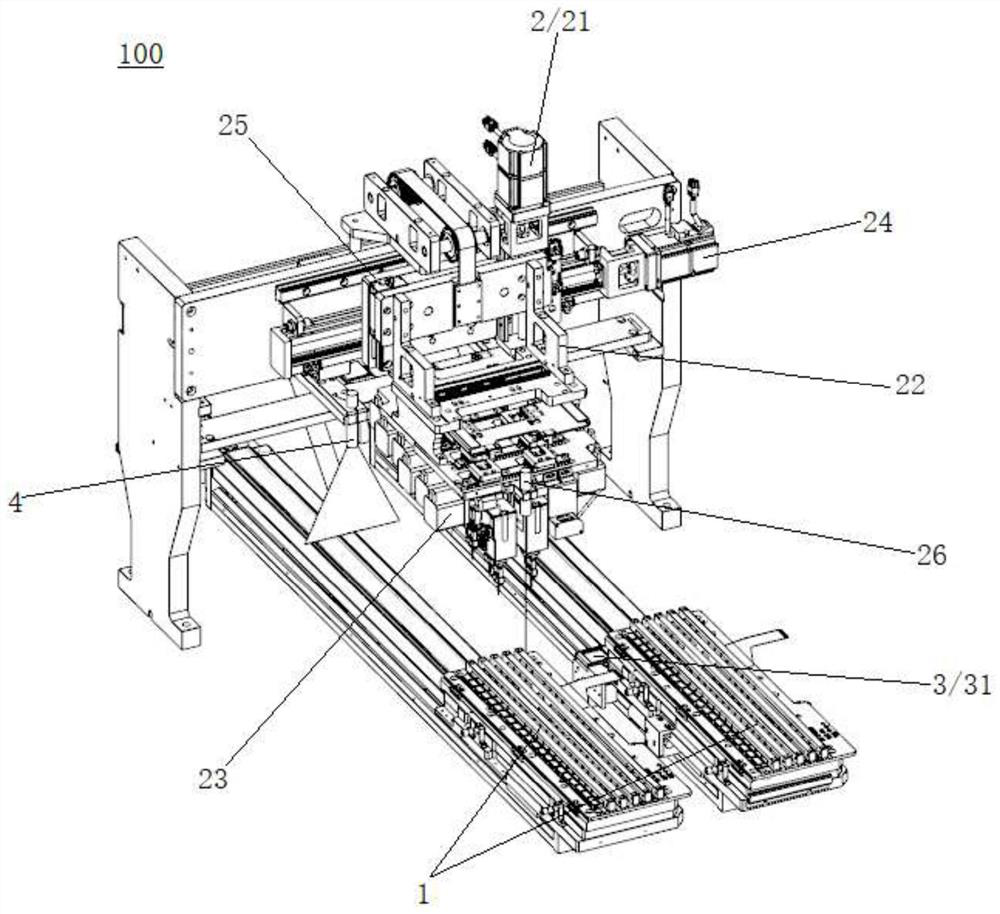

[0029] Please refer to Figure 1-Figure 4 , the present embodiment is a keycap detection mechanism 100 that can effectively avoid the pull hook of the drawing block from being broken. The test head module 2 and the visual detection module 3 for acquiring the position of each pull hook 234 .

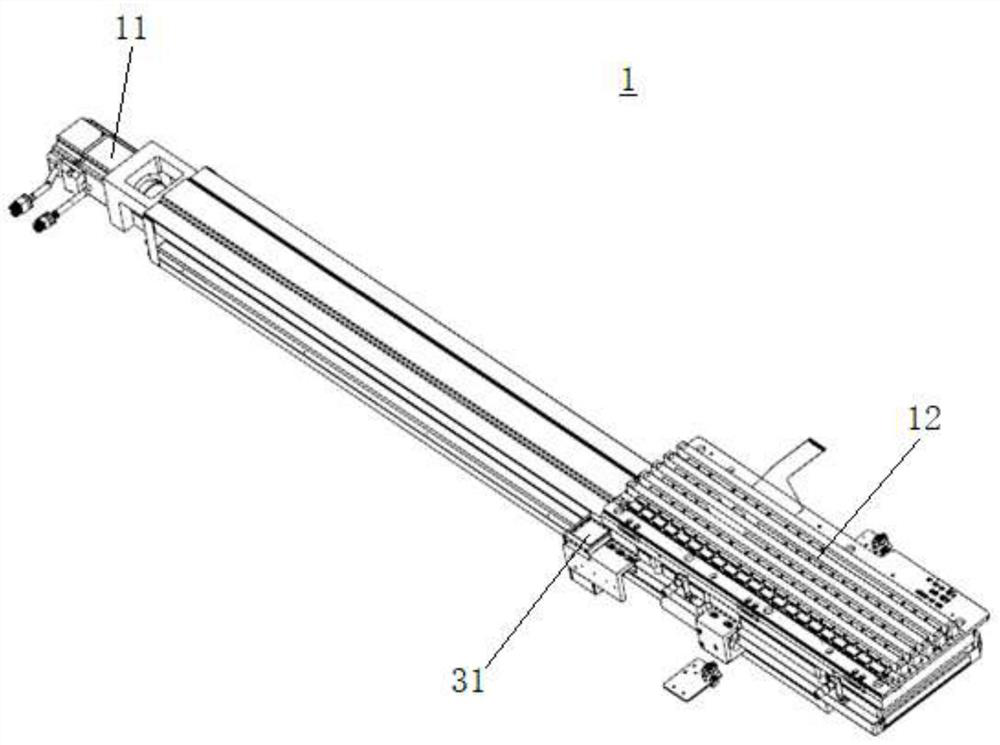

[0030] The keyboard loading and unloading conveying module 1 includes a Y-axis transfer mechanism 11 and a keyboard detection jig 12 driven by the Y-axis transfer mechanism 11 to move horizontally along the Y-axis.

[0031] The pull-out test head module 2 includes a Z-axis transfer mechanism 21 , a support frame 22 driven by the Z-axis transfer mechanism 21 to move up and down, and several test head assemblies 23 fixed on the support frame 22 .

[0032] The test head assembly 23 includes a first driving member 231, a pressure sensor 232 driven by the first driving member 231 to move up and down, a drawing block 233 arranged at the sensing end of the pressure sensor 232, and a drawing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com